Material for pressure measurement

A pressure and substrate technology, applied in the field of pressure measurement materials, which can solve problems such as inability to use products, concentration analysis or control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] (Preparation of preparation liquid for color-forming agent layer formation)

[0082] The microcapsules can be obtained in the form of a dispersion as described above, and the dispersion of the microcapsules can also be directly used as a preparation solution for forming a color-forming agent layer containing an electron-donating leuco dye precursor (especially for coating). liquid). In addition, a buffer such as starch or starch derivative fine powder, cellulose fiber powder, water-soluble polymer binders such as polyvinyl alcohol, vinyl acetates, acrylic acid, etc. may be further added to the dispersion of microcapsules obtained above. Hydrophobic polymer binders such as styrene-butadiene copolymer latex, fluorescent whitening agents, defoamers, penetrating agents, ultraviolet absorbers, and preservatives are used as preparation solutions (especially coating solutions).

[0083] The thus-obtained preparation solution (particularly, the coating solution) is applied to ...

Embodiment 1

[0101] -Preparation of Microcapsule Liquid (A) Including Electron Donating Leuco Dye Precursor-

[0102] Solution A was obtained by dissolving 9 parts of the following compound (A) which is an electron-donating leuco dye precursor in 70 parts of diarylethane. Next, 0.4 parts of a butylene oxide adduct of ethylenediamine dissolved in 1 part of methyl ethyl ketone was added to the solution A being stirred to obtain a solution B. Further, 2 parts of a trimethylolpropane adduct of toluene diisocyanate dissolved in 1 part of methyl ethyl ketone was added to the solution B being stirred to obtain a solution C. Then, the above-mentioned solution C was added to a solution obtained by dissolving 6 parts of polyvinyl alcohol in 150 parts of water, and emulsified dispersion was performed. 300 parts of water were added to the emulsified and dispersed emulsion, heated to 70° C. while stirring, and cooled after stirring for 1 hour. Water was added to adjust the concentration to obtain a m...

Embodiment 2

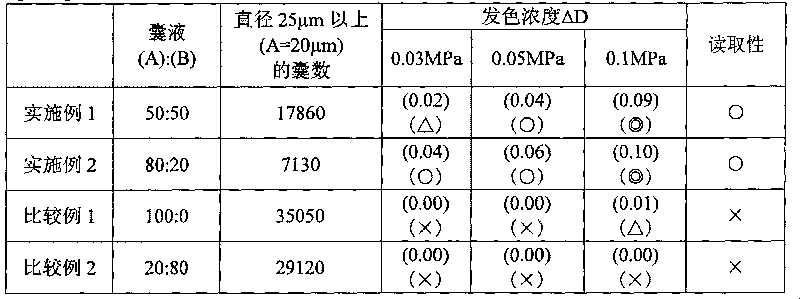

[0131] Mix 80 parts of microcapsules (A) containing electron leuco dye precursors prepared in Example 1 and 20 parts of microcapsules (B) containing electron leuco dye precursors. The quality of the mixed microcapsule liquid after drying is 5.0g / m with a bar coater 2 The standard was coated on a polyethylene terephthalate (PET) sheet with a thickness of 75 μm, and dried to obtain an electron-donating leuco dye sheet. Evaluation and measurement were performed in the same manner as in Example 1 using this electron-donating leuco dye sheet. The results of evaluation and measurement are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com