Advanced treatment method for pesticide industrial wastewater

An advanced treatment and pesticide technology, applied in the field of quinafos pesticide wastewater treatment, can solve the problems of wastewater CODcr difficulty, unable to meet the discharge standards, etc., achieve the effect of no secondary pollution, low labor intensity of workers, and achieve discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

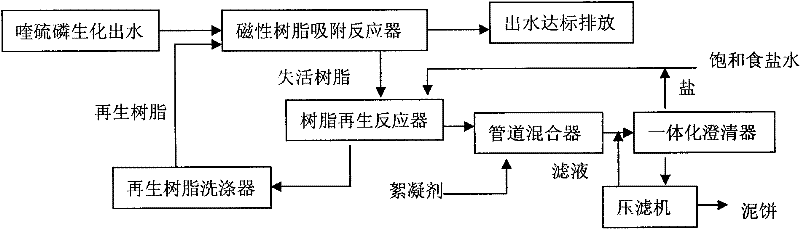

[0009] The steps are as follows: the process flow diagram is as follows figure 1 .

[0010] a) Continuous dynamic adsorption of Quetiafos pesticide production wastewater and magnetic resin after aerobic biochemical treatment. The upflow suspended bed magnetic resin contact reactor is used as the adsorption reactor, and the water is continuously fed in and out. The temperature of the incoming water is controlled at 15-30°C, PH6-9, CODcr≯200mg / l, and the ratio of water flow (inlet and outlet water: of magnetic resin) Weight)≯66.7:1. Effluent, CODcr≤50mg / l, up to standard discharge. Of course, the lower the influent flow rate, the better the effect of water treatment can be guaranteed. After the aerobic biochemical treatment, the wastewater produced by Quetiaphos pesticide is continuously and dynamically adsorbed by the magnetic resin. For example, the wastewater produced by Quetiaphos pesticide is reduced from 180-200 mg / l mg / l CODcr at the influent to 50 mg / l;

[0011] b) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com