Ammoximation reaction of ketone or aldehyde

A technology of ammoximation reaction and aldoaminoxime, which is applied in the field of ammoximation reaction of ketones or aldehydes, can solve the problems that the efficiency is greatly affected by the concentration of the catalyst, difficult large-scale operation, and slow separation rate, etc., so as to reduce energy consumption , Prolong the regeneration cycle and improve the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

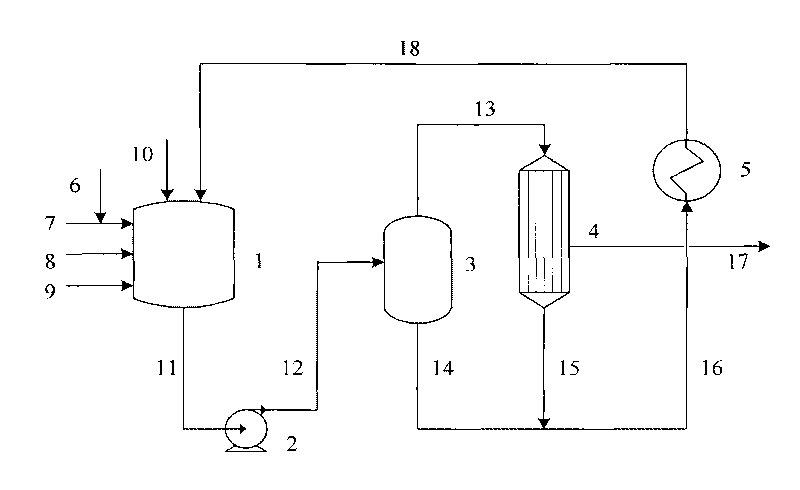

[0065] For the reaction process, see figure 1 . The volume of the reactor is 500 liters, the diameter of the hydrocyclone is 10mm, the separation element is an inorganic ceramic membrane tube with 19 channels φ4, and the effective filtration area is 0.2m 2 , The slurry is forced to circulate by a circulation pump.

[0066] Concrete feed parameter, separation system parameter and reaction result are as follows:

[0067] Cyclohexanone = 46 kg / hour

[0068] Hydrogen peroxide containing 27.5% by weight of hydrogen peroxide = 65 kg / hour

[0069] Tert-butanol (about 15w% water) = 120 kg / h

[0070] Liquid ammonia = 9 kg / hour

[0071] Reaction temperature = 83±1°C

[0072] Reaction pressure = 0.3MPa (gauge pressure)

[0073] Catalyst concentration = 3.2% by weight

[0074] The average residence time of the material in the reactor = 72 minutes

[0075] Filtration system recoil cycle = 30 minutes

[0076] Filtration system recoil time = 3 seconds

[0077] Slurry inlet pressur...

Embodiment 2

[0087] Reaction flow see figure 1 , other conditions were the same as in Example 1, and the fluxes of solid-liquid separation membranes under different catalyst concentrations of 0, 1.1, 3.2, 5.1, 8.3, and 9.8% by weight were investigated. The experimental results are shown in Table 1.

Embodiment 3

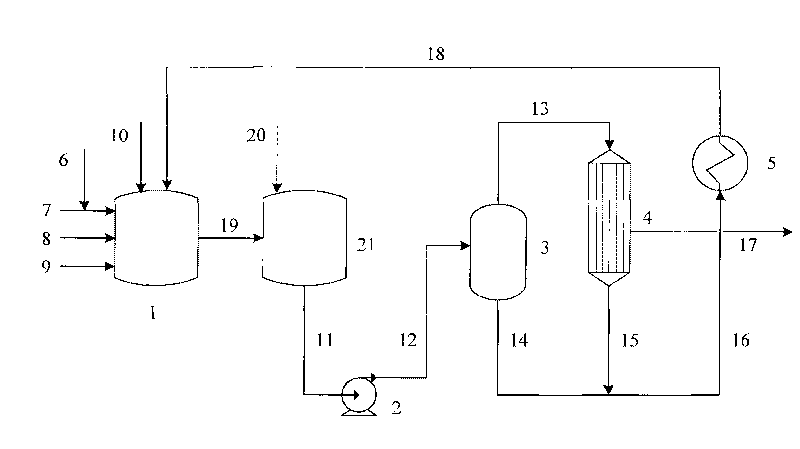

[0108] This example illustrates that the method provided by the present invention adopts the mode of two reactors connected in series. For the reaction process, see image 3 . The volumes of the two reactors are 500 liters respectively, and the two reactors are operated in series. The slurry in the first reactor enters the second reactor through the pressure difference, and the separation system after the second reactor is the same as in Example 1, and the type and size of the ceramic membrane and the hydrocyclone are the same as in Example 1.

[0109] Concrete feed parameter, separation system parameter and reaction result are as follows:

[0110] First Reactor (1)

[0111] Cyclohexanone = 46 kg / hour

[0112] Hydrogen peroxide containing 27.5% by weight of hydrogen peroxide = 62.8 kg / hour

[0113] Tert-butanol (about 15w% water) = 120 kg / h

[0114] Liquid ammonia = 9 kg / hour

[0115] Reaction temperature = 83±1°C

[0116] Reaction pressure = 0.3MPa (gauge pressure)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com