A method for separating huperzine A in Melaleuca tower by foam separation method

A foam separation method and a technology for huperzine A, which are applied in the field of huperzine A in the separation of melaleuca towers by the foam separation method, can solve the problems of short processing time, inconvenient industrialization, and high cost, and achieve low cost, easy industrialization, and low energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

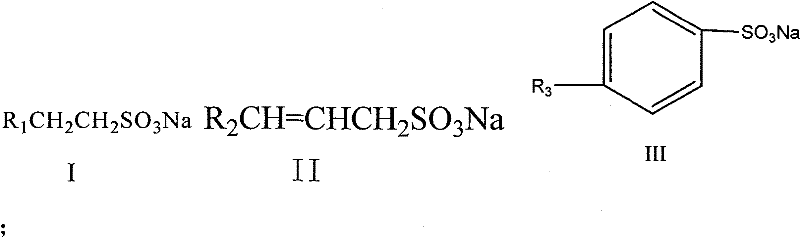

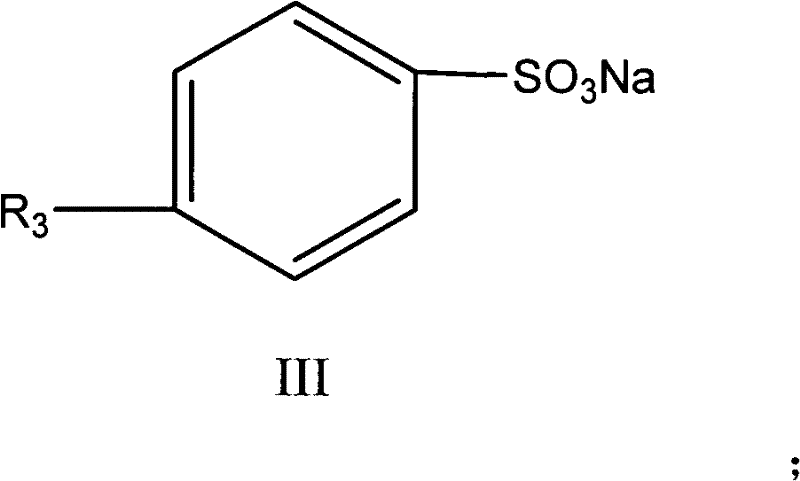

[0034] Weigh 100 grams of melaleuca extract (commercially available, Xi'an Sanwei Biotechnology Co., Ltd.) (with 1% huperzine A content), dissolve it in 200ml of ethanol and stir evenly to obtain a dilute total alkali solution. Then total alkali dilute solution and activator sodium dodecyl sulfonate (3 grams) are dropped in the foam separation tower (Terada Pump Terada Pump Manufacturing Institute MS-S small foam separator, total capacity 2L, the same below), foam separation The column height of tower and internal diameter ratio are 14: 1, and the temperature in the control foam separation tower is 30 ℃, stirs evenly, introduces air through the bottom of the tower, and the gas flow rate of air is 120ml / min, carries out bubbling, and the foam that obtains is passed through the tower The top is discharged into the storage tank to obtain foam liquid, and the foam is collected until no foam is produced. The foam liquid was centrifuged at 10000rpm for 15 minutes, and the centrifuge...

Embodiment 2

[0036] Weigh 120 grams of Melaleuca extract (commercially available, Xi'an Sanwei Biotechnology Co., Ltd.) (with a huperzine A content of 2%), dissolve it in 250 ml of ethanol and stir evenly to obtain a dilute total alkali solution. Then total alkali dilute solution and active agent sodium dodecylbenzenesulfonate (7 grams) are poured in the foam separation tower, the temperature in the control foam separation tower is 30 ℃, introduces air through the bottom of the tower, and the gas flow rate of air is 150ml / min, carry out bubbling, and the foam obtained is discharged into the storage tank from the top of the tower to obtain a foam liquid, and the foam is collected until no foam is produced. Centrifuge the foamy liquid at 10,000rpm for 20 minutes, take the centrifuged precipitate, put it into 15ml of 10wt% NaOH solution for full reaction, stir so as to remove sodium dodecylbenzenesulfonate, filter and take the filter cake to obtain Huperzine A Crude product, huperzine A crude...

Embodiment 3

[0038] Weigh 140 grams of melaleuca extract (commercially available, Xi'an Sanwei Biotechnology Co., Ltd.) (3% huperzine A content), dissolve it in 280ml of ethanol to obtain a dilute total alkali solution. Then total alkali dilute solution and active agent sodium dodecenyl sulfonate (12 grams) are poured in the foam separation tower, the temperature in the control foam separation tower is 30 ℃, introduces air through the bottom of the tower, and the gas flow of air is 150ml / min, for bubbling, and the obtained foam is discharged from the top of the tower into the storage tank to obtain a foam liquid, and the foam is collected until no foam is produced. Centrifuge the foam liquid, centrifuge at 10000rpm for 25 minutes, take the centrifuged precipitate, then put the resulting precipitate into 24ml 10wt% NaOH solution to fully react, stir, filter, remove sodium dodecenyl sulfonate, and filter The cake obtains the Huperzine A crude product, and the Huperzine A crude product is re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com