Chitin fiber and preparation method thereof

A chitin fiber and chitin technology, applied in the fiber field, can solve the problems of poor spinnability and weaving performance of chitin fiber, low mechanical properties of chitin fiber, endangering the health of operators, etc., and achieve excellent mechanical properties , good dry elongation at break, good solubility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

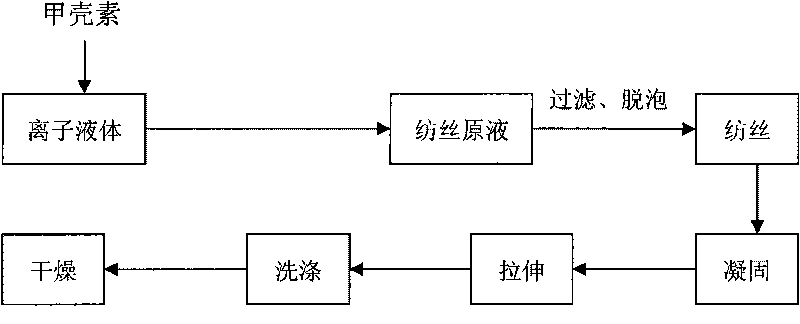

Method used

Image

Examples

Embodiment 1

[0052] (1) Pulverizing chitin, then adding an ionic liquid to dissolve it to obtain a spinning stock solution;

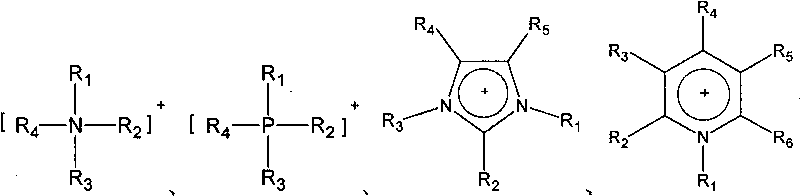

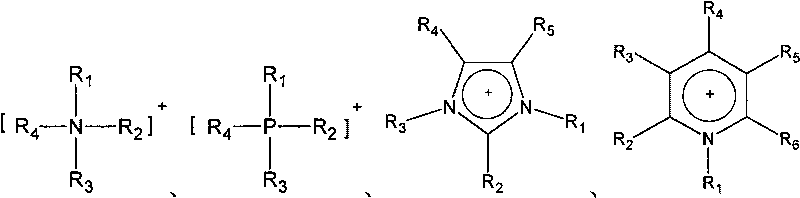

[0053] Firstly, the chitin is pulverized by using a chitin-specific pulverizer so that the obtained chitin has a fineness of about 300 meshes. The chitin is chitin with a deacetylation degree of 0%. The pulverized chitin is put into the ionic liquid for dissolving, wherein the amount of the ionic liquid is 85% of the weight of the spinning stock solution, and it is dissolved at a temperature of 50° C. for 50 hours. When dissolving, it is stirred so that the chitin is dissolved in the ionic liquid fully dissolved. After fully dissolving, the spinning stock solution is obtained, and its concentration is 15%.

[0054] (2) filtering and defoaming the spinning dope, and then performing dry spray-wet spinning;

[0055] After the spinning dope is filtered and defoamed, dry spray-wet spinning is carried out, and filament bundles are obtained after spinning. When perform...

Embodiment 2

[0060] (1) Pulverizing chitin, then adding an ionic liquid to dissolve it to obtain a spinning stock solution;

[0061] First, the chitin is crushed, and a chitin-specific pulverizer is used during the crushing, so that the obtained chitin has a fineness of about 400 meshes. The chitin is chitin with a deacetylation degree of 40%. The pulverized chitin is put into an ionic liquid for dissolving, wherein the amount of the ionic liquid is 75% of the weight of the spinning stock solution, and it is dissolved for 8 hours at a temperature of 100°C. The ionic liquid is [EMIN]Ac- (the Chinese name is Acetate (1-ethyl-3-methylimidazolium salt) aqueous solution, when dissolving, stir to allow chitin to fully dissolve in the ionic liquid. After fully dissolving, the spinning stock solution is obtained, and its concentration is 25%.

[0062] (2) filtering and defoaming the spinning dope, and then performing dry spray-wet spinning;

[0063] After the spinning dope is filtered and defoa...

Embodiment 3

[0068] (1) Pulverizing chitin, then adding an ionic liquid to dissolve it to obtain a spinning stock solution;

[0069] Firstly, the chitin is pulverized by using a chitin-specific pulverizer so that the obtained chitin has a fineness of about 500 meshes. The chitin is chitin with a deacetylation degree of 80%. Put the pulverized chitin into the ionic liquid for dissolving, wherein the amount of the ionic liquid is 95% of the weight of the spinning stock solution, dissolve for 1 hour at a temperature of 150°C, and stir when dissolving, so that the chitin is dissolved in the ionic liquid fully dissolved. After fully dissolving, the spinning dope was obtained, the concentration of which was 5%.

[0070] (2) filtering and defoaming the spinning dope, and then performing dry spray-wet spinning;

[0071] After the spinning dope is filtered and defoamed, dry spray-wet spinning is carried out, and filament bundles are obtained after spinning. When performing dry jet-wet spinning,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap