Surface modification processing method and device of MEMS microcomponent

A technology for the surface of micro-devices and workpieces, applied in the field of surface treatment of micro-devices, can solve problems such as not being retrieved, and achieve the effects of improving fatigue resistance and stress corrosion resistance, easier process and control, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

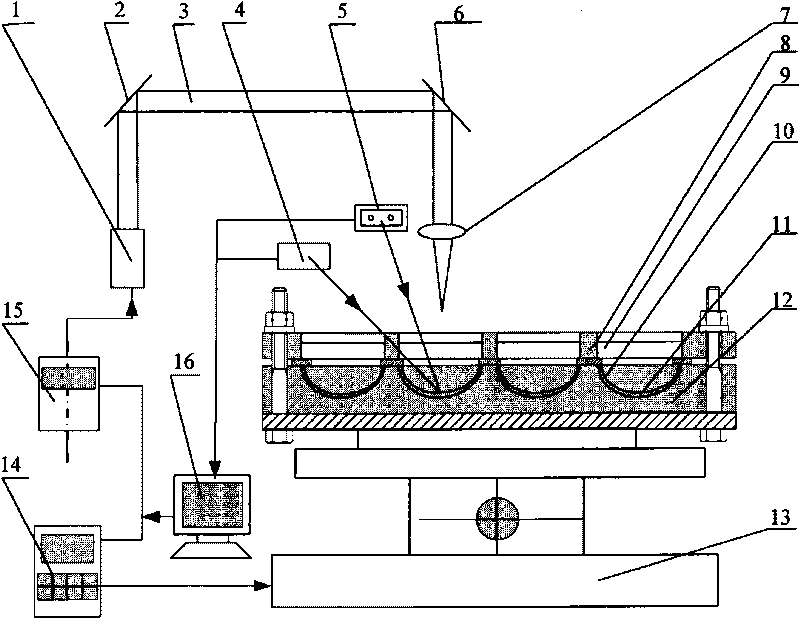

[0037] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] The device includes a laser generator 1 and a light guide system, a shot blasting head 7 , a fixture system 12 , a computer control system 16 , a CCD monitoring system 5 and an X-ray micro-diffraction system 4 . The laser is a Nd:YAG Q-switched nanosecond pulse laser, which generates laser pulses with an energy of 100-500 μJ and a duration of 50 nanoseconds. The light guide system includes a reflector 2 , a light guide element 3 , and a rotating reflector 6 . The workpiece fixture system includes a workpiece fixture 12 and a multi-axis linkage worktable 13. This device has three coordinates of movement and two rotations, and can realize five-axis linkage, so that laser shot peening can be conveniently implemented on the workpiece 11. The control system is composed of machine tool controller 14 , laser controller 15 and computer contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com