Infrared positive thermal-sensitive imaging composition

A technology of infrared thermosensitive and imaging composition, which is applied in the direction of photosensitive materials, printing, and printing plate preparation for optomechanical equipment, and can solve the problems of reducing the use function of printing plates, affecting compatibility, and low chemical resistance. Achieve high film retention, excellent chemical resistance, and high development latitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-7

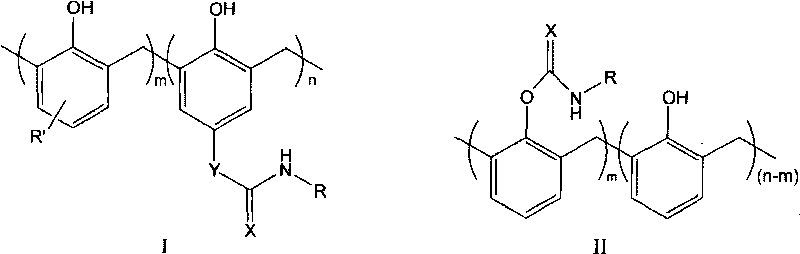

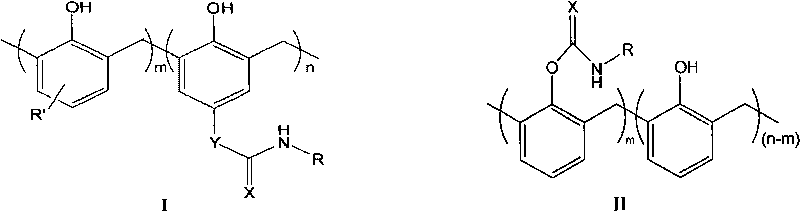

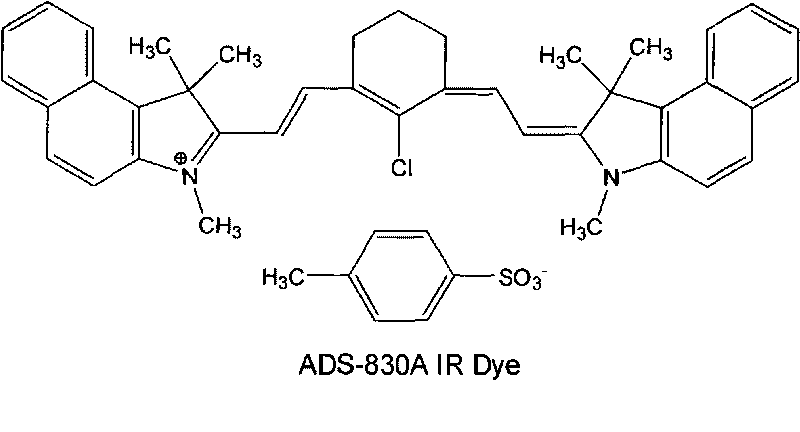

[0138] On the obtained plate base, at 1.6g / cm 2 Coating amount Coating thermosensitive positive imaging composition: 22.52g polymer P1 (or P9, or P18, or P20, or P23, or P25, or P29, 0.71g IR830A infrared absorber, 250.00g γ-butylene Lactone / acetone / isobutyl ketone = 150 / 200 / 650 mixed solvent. The coated sample plate was dried in an oven at 120°C for 10 minutes to obtain the original plate of thermal positive CTP.

[0139] The obtained original plate was mounted on a Creo Trendsetter 800 Quantum type CTP plate-setter, using an 830nm laser, a drum rotation speed of 158rpm, and a laser power of 8W for scanning exposure. The exposed plate was developed with XingraphicsDV-F3 developer (from Chengdu Xintu Printing Technology Co., Ltd.) for 40 seconds at 25°C, and all the exposed parts of the original plate were completely dissolved, while the non-exposed parts were not dissolved. The image of the developed plate is clear, with sharp and neat edges.

example 8-14

[0144] Except that the 0.7g IR830A infrared absorber in Example 1-7 was changed to 1.01g of 3-10 μm carbon black, other operations were unchanged, and the results similar to Example 1-7 were obtained.

example 15-22

[0149] On the obtained plate base, at 1.6g / cm 2 The amount of coating coating thermosensitive positive imaging composition: 19.80g polymer P18, 0.55g IR830A infrared absorber, 0.40g MCF312 surfactant, 0.15g F-176 surfactant, 1.00g crystal violet lactone , 0.75g of phthalic anhydride was dissolved in 250g of γ-butyrolactone / acetone / isobutyl ketone=150 / 200 / 650 mixed solvent. The coated sample plate was dried in an oven at 120°C for 10 minutes to obtain the original plate of thermal positive CTP.

[0150] The obtained original plate was mounted on a Creo Trendsetter 800 Quantum type CTP plate-setter, and an 830nm laser was used with a drum rotation speed of 158rpm for scanning exposure. The exposed plate was developed at 25°C with Xingraphics DV-F3 developer.

[0151] Replace P1 in the example with P10, P18, P21, P23, P24, P28, and P29, and keep the other components unchanged. Measure the exposure energy when clear images are obtained without bottom dirt, and the following data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com