Method for preparing rice protein polypeptide powder from rice residue protein

A technology of rice dregs protein and rice protein, applied in the protein composition of vegetable seeds, protein food processing, protein food ingredients, etc., can solve the problems of low yield of bioactive peptides, long preparation process, low efficiency of enzymatic hydrolysis, etc. , to achieve high protein and peptide content, reduce production costs, and reduce the effect of protein molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

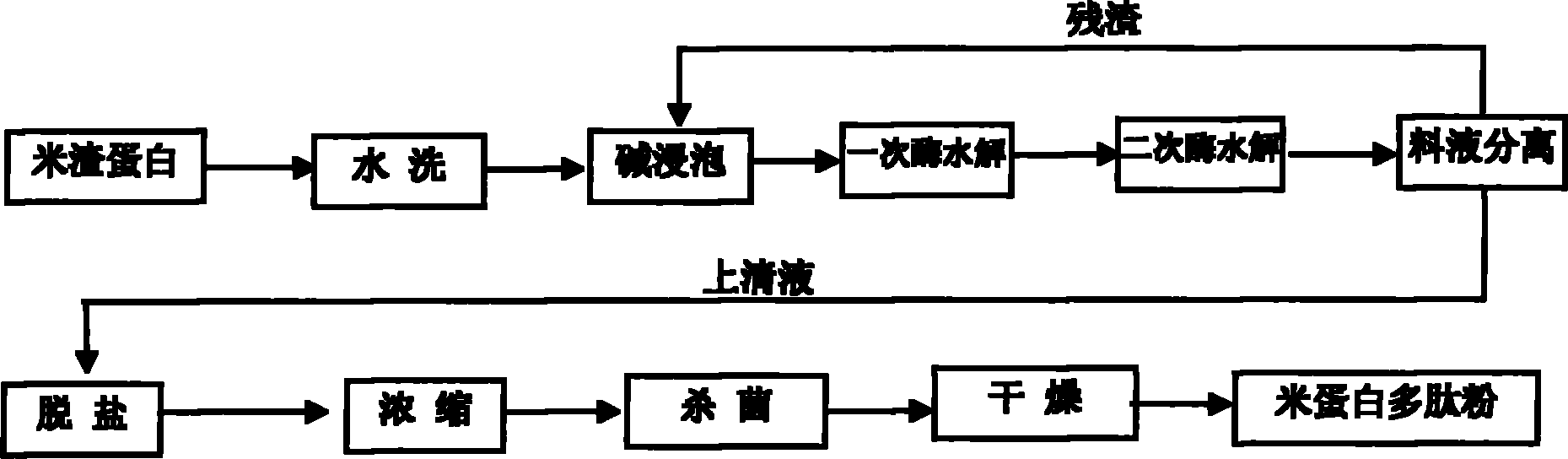

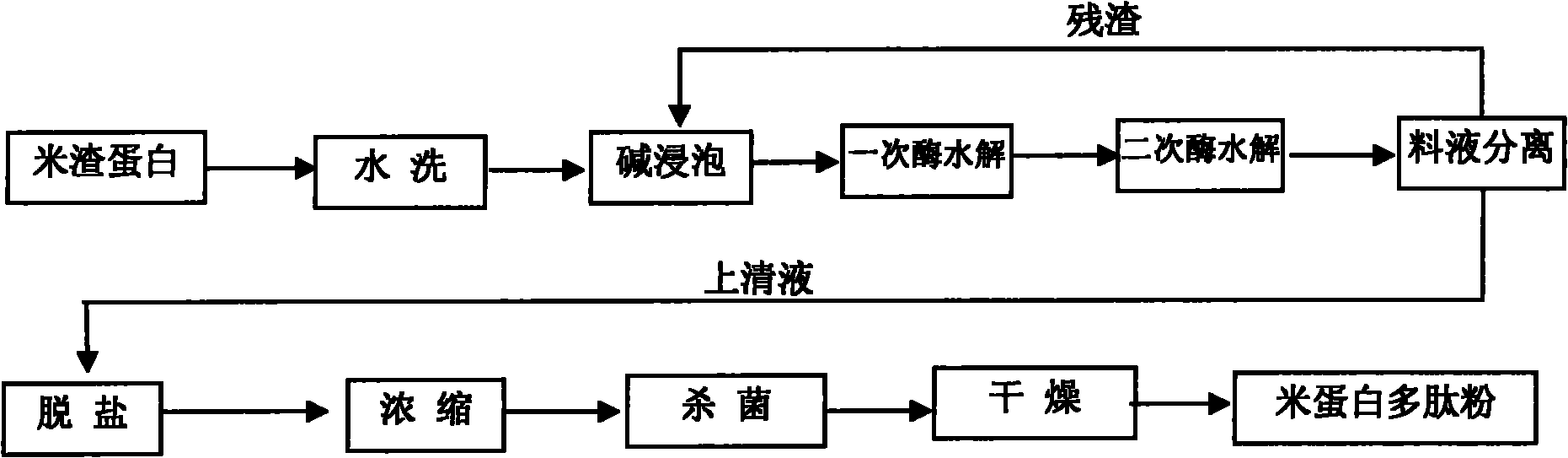

[0038] Attached figure 1 The process method for preparing rice protein powder is prepared in a laboratory. Weigh 100g of rice dregs (containing about 60% protein) in a beaker, add 500ml of water, stir thoroughly, spread filter paper with a funnel to filter, take the filter residue and repeat the above steps twice, and fully wash. Put the washed slag in a jacketed beaker, add 500ml of water, stir evenly, add dropwise 1mol / l NaOH solution to pH 11, maintain the temperature of the material liquid at 55°C, soak for 1.5 to 2 hours, the pH drops to 10, add protein dry basis 0.6 g of alkaline protease (Novozymes) for hydrolysis, and when the pH continued to drop to 8.5, add 0.3 g of papain (Novozymes) on a dry basis to the feed liquid, and when the pH dropped to 6.5, stop the reaction. , Centrifuge the feed liquid with a centrifuge, collect about 480ml of the supernatant, first use cationic resin and then use anionic resin to desalt, the conductivity is reduced to about 60μm / s, and ...

Embodiment 2

[0041] Attached figure 1 The process for preparing rice protein powder is an industrial example. Feed 200kg of rice dregs (containing about 60% protein), add water at a ratio of 1:5, stir and mix, enter the three-stage cyclone for washing and separation, the washing water volume is 600kg, and the protein weight after washing is about 630kg, and pumped into In the reaction tank, adjust the concentration to 10°Be, the feed liquid is about 900kg, heat the feed liquid temperature to 55°C, keep stirring at a constant temperature and constant speed, add alkali to adjust the pH to 11, soak for 1.5 to 2 hours, and the pH at this time is about Down to about 10, add 1.2kg alkaline protease (Novozymes) for hydrolysis, react until the pH drops to 8.5, add 0.6kg papain (Novozymes), react until the pH drops to about 6.5, and discharge, Enter the plate and frame filter press, collect 880kg of supernatant, conduct electrodialysis desalination on the supernatant, the output conductance is les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com