Phosphorus-free corrosion and scale inhibitor

A technology of phosphorus-free corrosion and scale inhibitors, applied in the field of water treatment, can solve environmental pollution and other problems, and achieve the effect of reducing molecular weight, low price and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

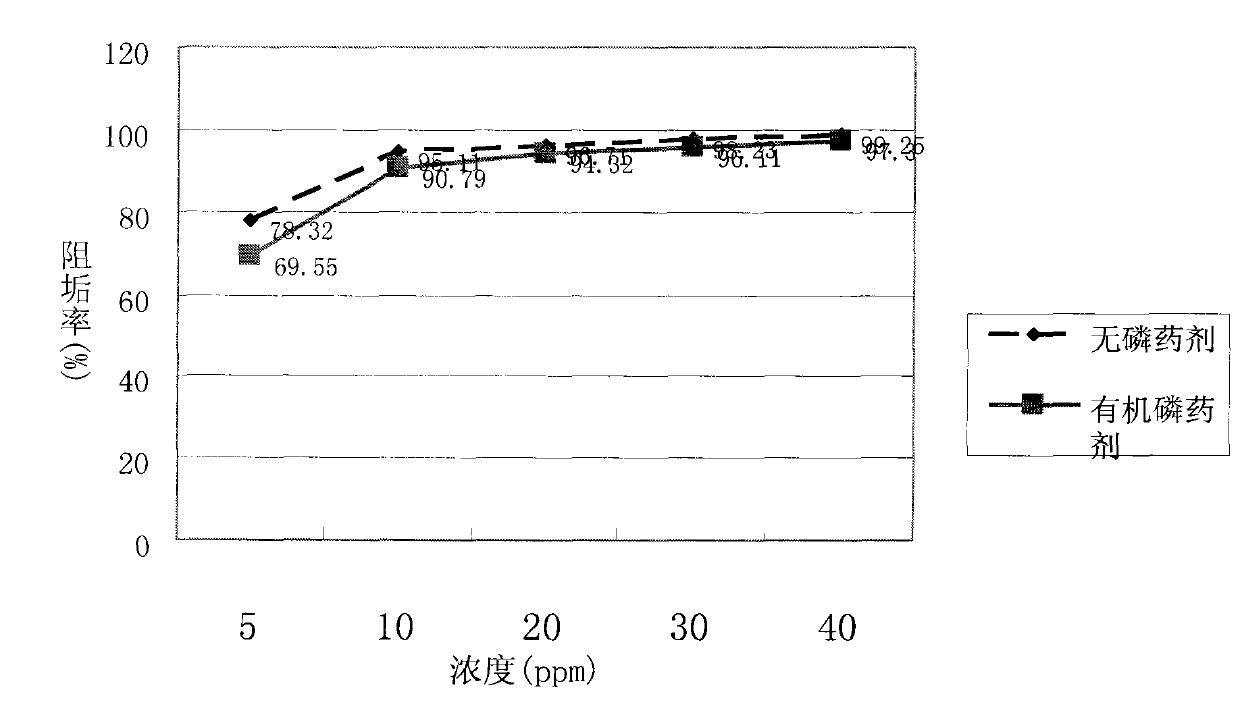

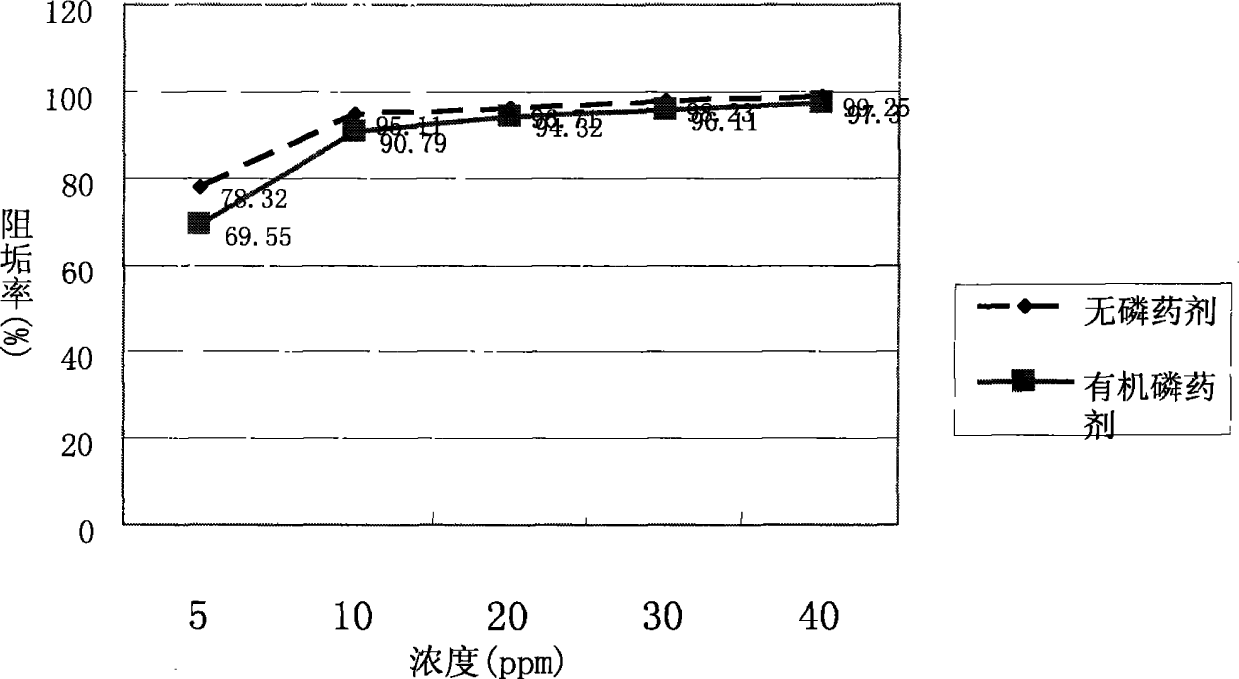

Image

Examples

Embodiment Construction

[0028] 1. Formula:

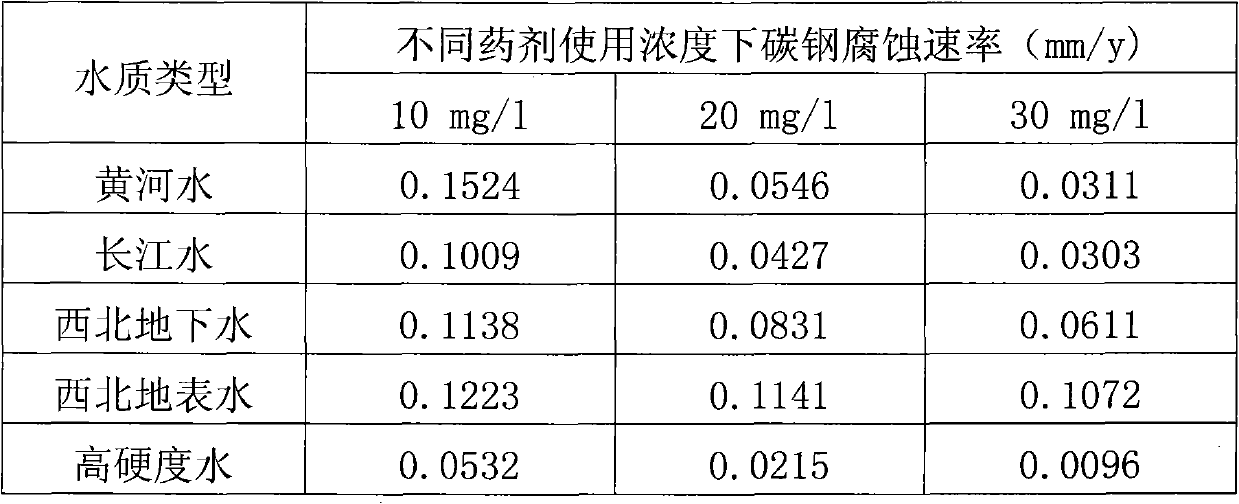

[0029] Itaconic acid-acrylic acid-acrylate copolymer 18-20%; 2-acrylamide-2-methylpropanesulfonic acid-diethylacrylamide polymer 8-10%; polyepoxysuccinic acid 9-11%; Hydrolyzed polymaleic anhydride 10-12%; Fluorescein 0.5-1.5%; Water 45-53%. The above formula is just a reference dosage, and it needs to be adjusted appropriately according to the specific water quality of the enterprise during use. For water with high hardness and high concentration ratio, the dosage of chemicals can be increased to meet the water quality requirements.

[0030] 2. The operation procedure of drug compounding:

[0031] (1) Pour a certain amount of room temperature water into the kettle. (Heat the water to about 26°C in cold weather).

[0032] (2) Add a certain amount of 2-acrylamide-2-methanesulfonic acid-diethylacrylamide polymer, and stir to turn it on, do not turn it off.

[0033] (3) Add a certain amount of polyepoxysuccinic acid to dissolve and stir for 20 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com