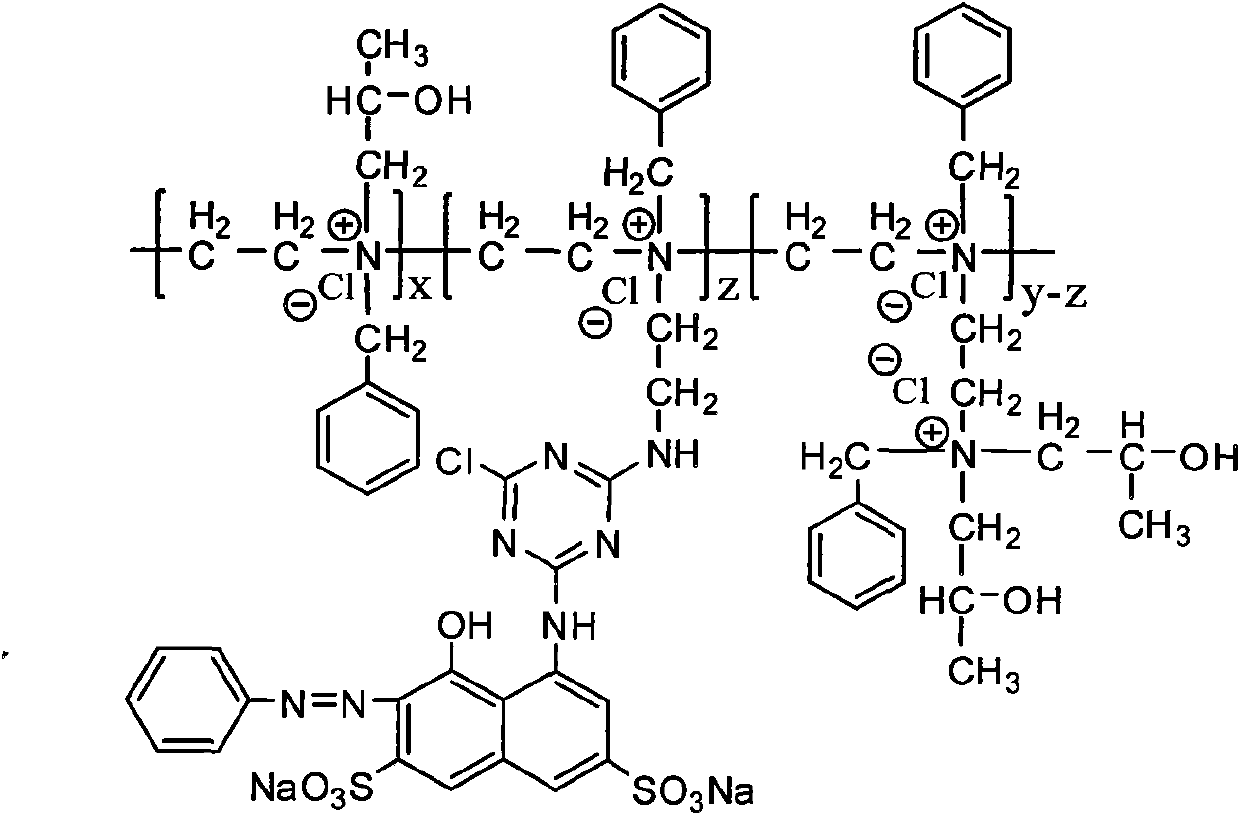

Antibacterial cation reactive dye and preparation and application thereof

A technology of reactive dyes and cations, which is applied in the field of antibacterial cationic reactive dyes and their preparation and application, can solve the problems of dyes losing antibacterial properties, easy hydrolysis, and lack of affinity for cotton fibers, etc., and achieve excellent color fastness, high affinity, and good The effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

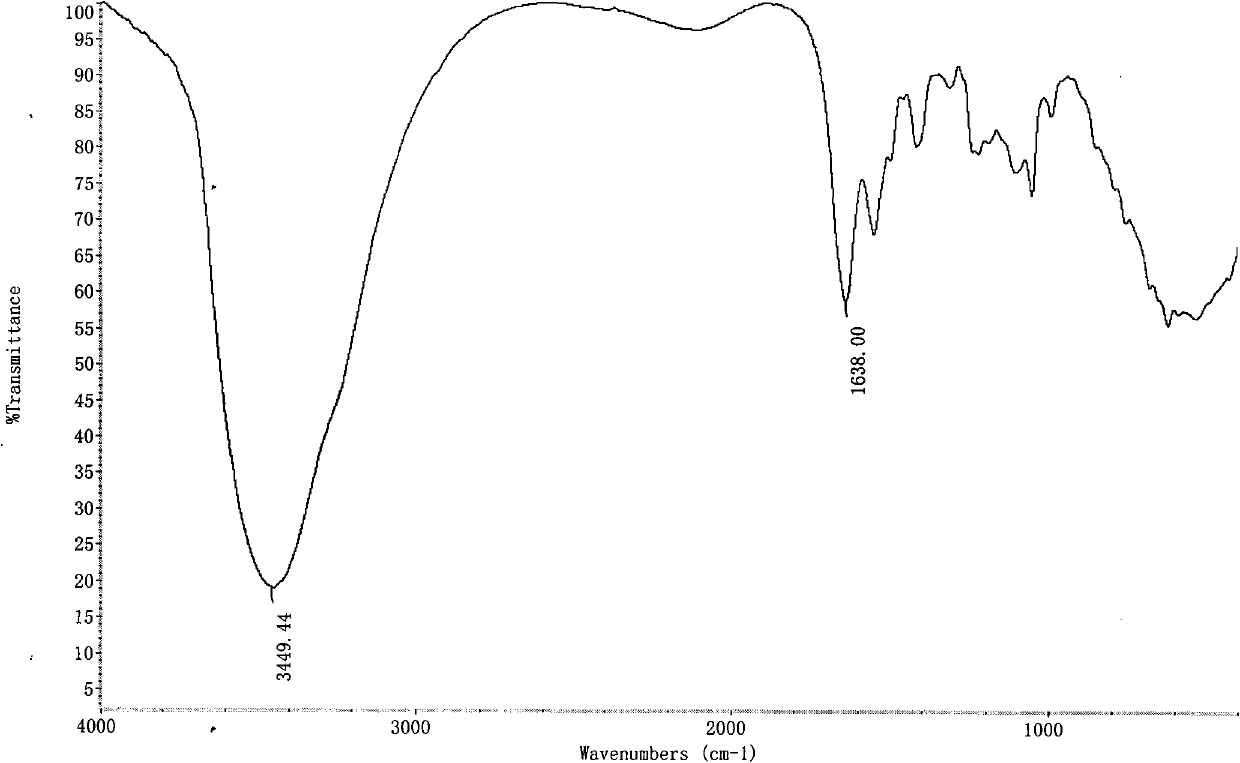

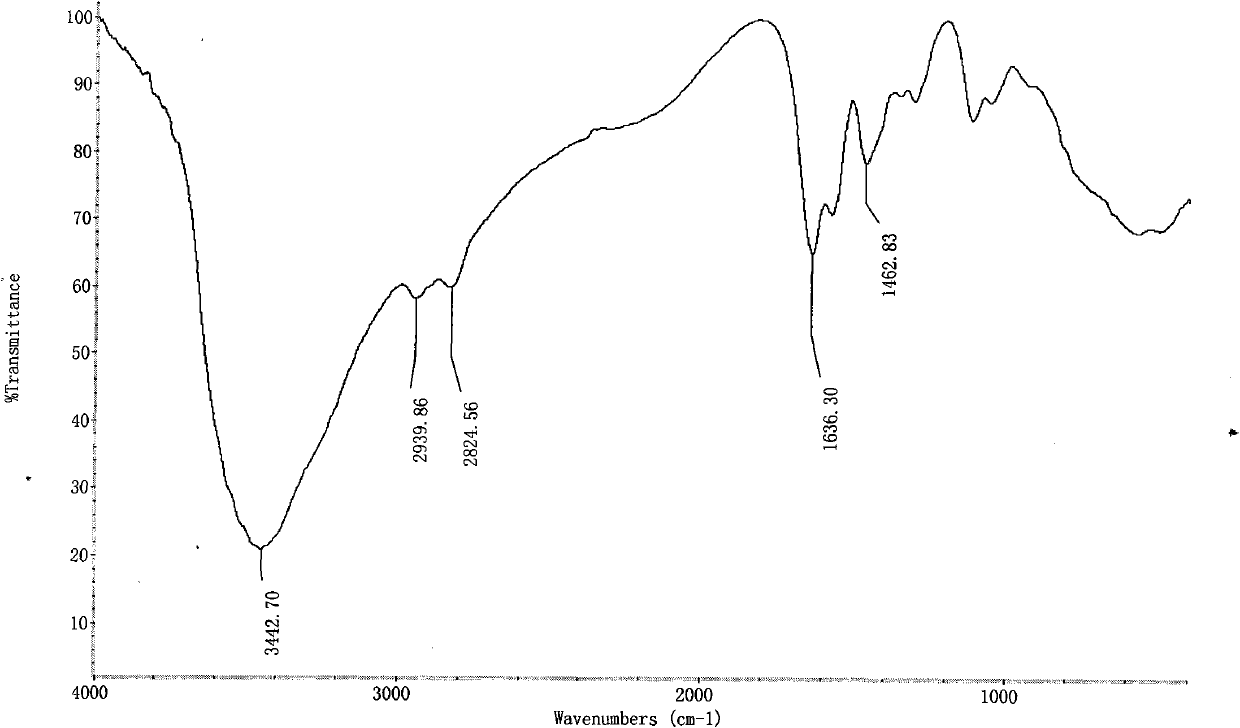

[0031] Dissolve 8.33g of polyethyleneimine (30% aqueous solution) with a degree of polymerization of 1550 to 1650 in 100mL of water, keep the temperature at 25°C, and add 3.07g (5mmol) of 3-phenylazo-4-hydroxy-5-[( 4,6-dichloro)-1,3,5-triazine]amino-2,7-sodium naphthalene disulfonate, TLC (n-propanol:concentrated ammonia water=3:1, v / v) monitoring the reaction to the starting material The dot disappears, add 300mL acetone and stir to precipitate a precipitate, after standing still, filter to obtain a red polymer dye, referred to as XPEI. The obtained product was washed with water and acetone (volume ratio 1:3), and the product was vacuum-dried in an oven at 30° C. for more than 12 hours, and the yield was 91%.

[0032] Wash the product of the above reaction and then dissolve it in 120mL of water, add it to a 250mL three-neck flask, add 8.5g of propylene oxide dropwise with a dropping funnel, maintain the temperature at 0-5°C with an ice-water bath, and continue the reaction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com