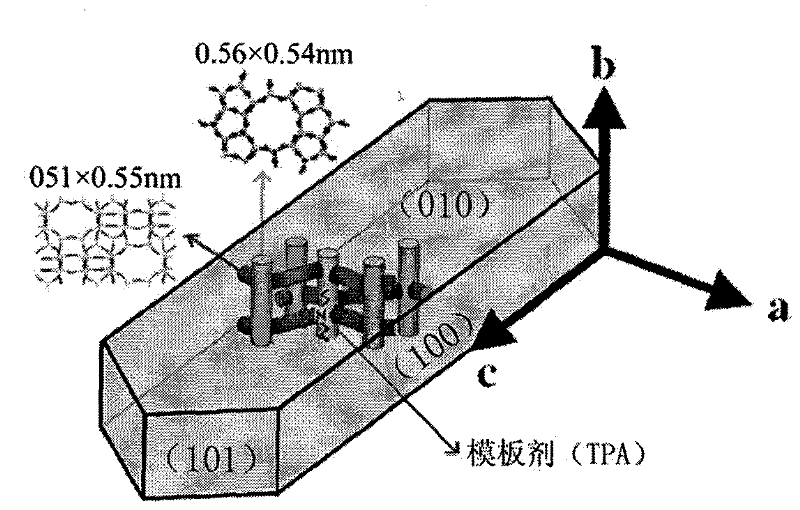

Method for preparing oriented molecular sieve membrane by using diauxic growth method

A secondary growth, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of poor orientation and a large number of seed layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

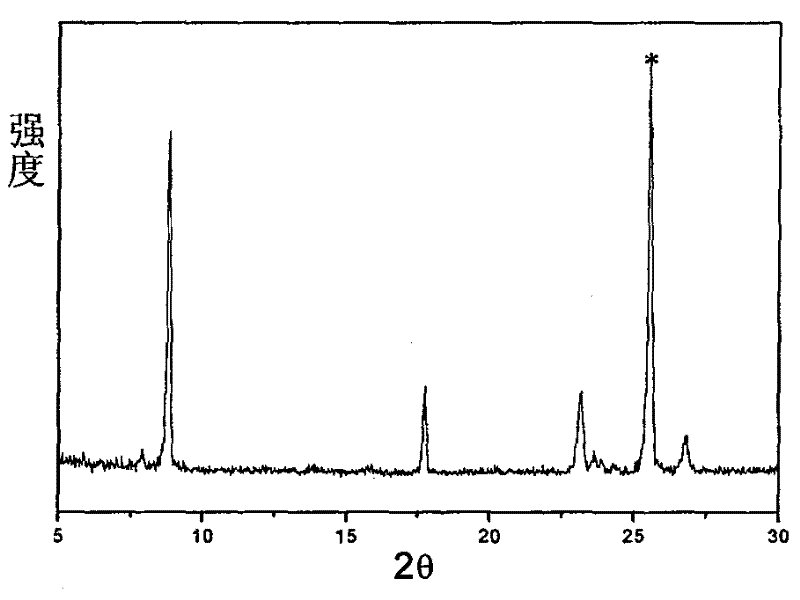

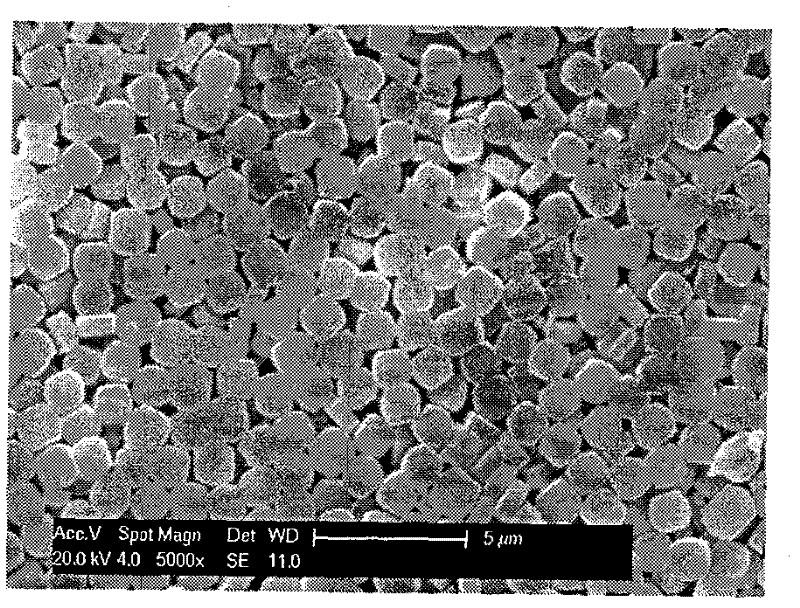

[0022] (1) Disperse 0.25 g of TS-1 seed crystals in 49.75 g of tetrapropylammonium hydroxide TPAOH aqueous solution to prepare seed crystal liquid, the pH of which is 3.5. Put a petri dish with built-in filter paper in the ultrasonic cleaner, put the carrier on the filter paper in the petri dish, soak the carrier and filter paper with tetrapropylammonium hydroxide TPAOH aqueous solution with pH=3.5, and set the temperature at 200W, 40KHz, 40 Under the ultrasonic condition of ℃, 0.5ml of the aforementioned seed liquid was added dropwise on the carrier, ultrasonicated until the surface of the carrier was dry, and then taken out to obtain a b-axis orientation TS-1 molecular sieve seed layer.

[0023] (2) Disperse 0.05 g of TS-1 seed crystals in 49.95 g of tetrapropylammonium hydroxide TPAOH aqueous solution according to the method of (1) to prepare a seed crystal solution, the pH of which is 6. Under ultrasonic conditions of 100W, 40KHz, and 65°C, 1ml of the aforementioned seed l...

Embodiment approach 2

[0026]The seed layer was prepared according to the method of (1) in Example 1. In the aqueous solution of 10.83ml tetrapropyl ammonium hydroxide (20%) TPAOH, add the water of 96.77ml, stir for 15 minutes, then dropwise add the silica sol (40%) of 16 grams wherein, the tetrabutyl titanate of 0.145 grams Dissolve the ester in 3.5ml of isopropanol, add it dropwise to the aforementioned sol at 0°C under the protection of nitrogen, stir for 20 minutes, heat up to 80°C, stir at this temperature, evaporate and remove the alcohol in the sol, and add water to The original liquid level is cooled to room temperature, stirred for 1 hour, and the secondary growth liquid is obtained, and its composition is: 1SiO 2 :0.004TBOT:0.1TPAOH:60H 2 O.

[0027] Put the carrier loaded with the seed crystal and the secondary growth solution together in the crystallization reaction kettle, place the carrier horizontally, and the carrier seed layer loaded with the seed crystal is in contact with the se...

Embodiment approach 3

[0029] Prepare the seed crystal layer according to the method of (2) in Example 1, on the basis of Example 2, according to the method of Example 2, add 56.68 to the aqueous solution of tetrapropyl ammonium hydroxide (20%) TPAOH of 7.04ml ml of water, stirred for 15 minutes, then added dropwise 11.09 g of tetrabutyl titanate to it, dissolved 0.145 g of tetrabutyl titanate in 3.5 ml of isopropanol, and dropped at 0°C under the protection of nitrogen Add to the aforementioned sol, stir for 20 minutes, raise the temperature to 82°C, stir at this temperature, evaporate and remove the alcohol in the sol, add water to the original liquid level, cool to room temperature, and stir for 1 hour to obtain the secondary growth solution. Its composition is: 1TEOS:0.008TBOT:0.13TPAOH:65H 2 O, secondary growth at 175°C for 36 hours to prepare a b-axis oriented TS-1 molecular sieve membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com