Algae-laden water separation process for scale and engineered treatment of high concentration algae slurry

A technology of algal water separation and high concentration, which is applied in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, dehydration/drying/thickened sludge treatment, etc. Without mechanized salvage of cyanobacteria, it is impossible to form large-scale, engineering, and solve problems such as salvaging cyanobacteria, so as to prevent and control eutrophication of water bodies, improve the quality of water body environment, and facilitate ecological restoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

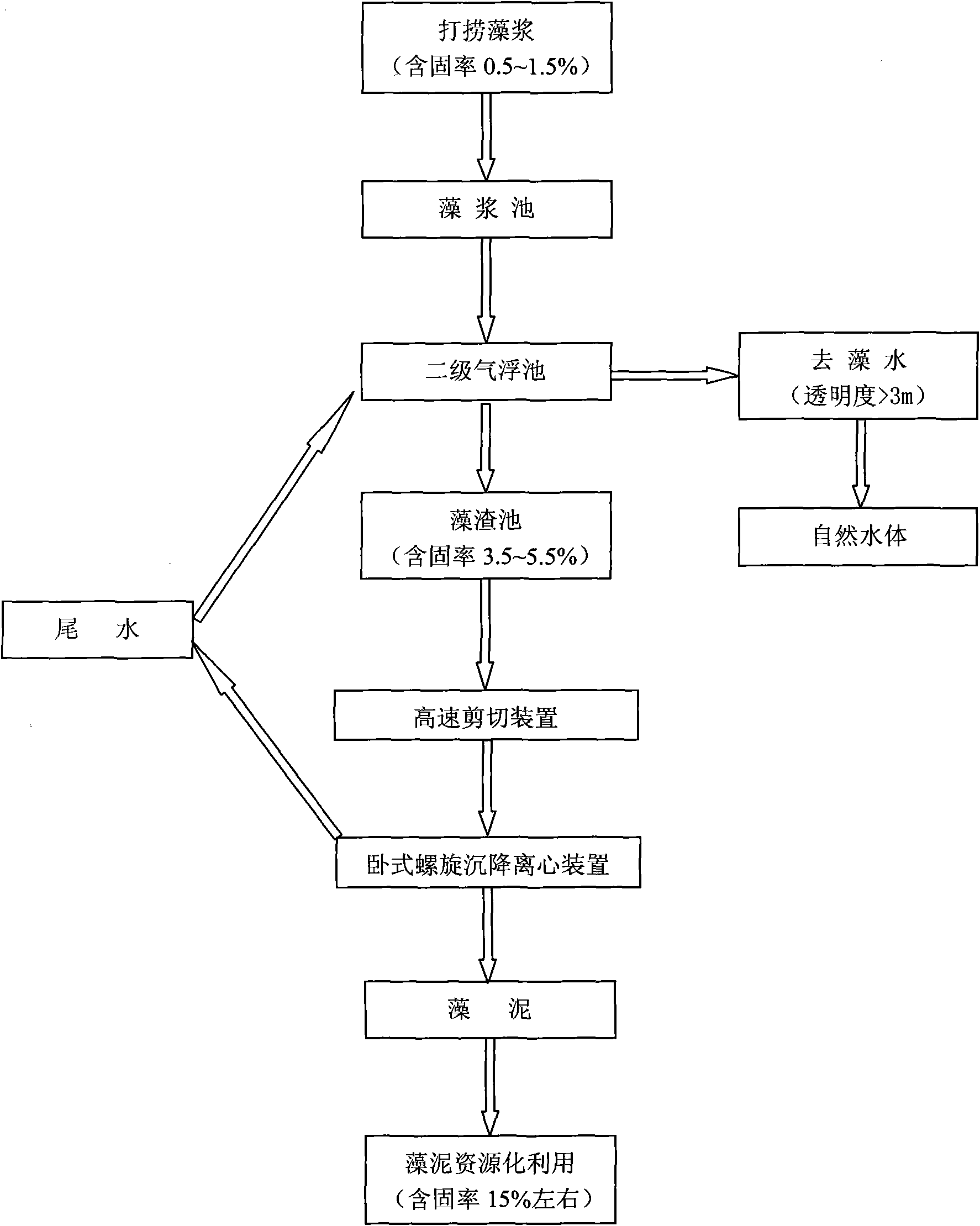

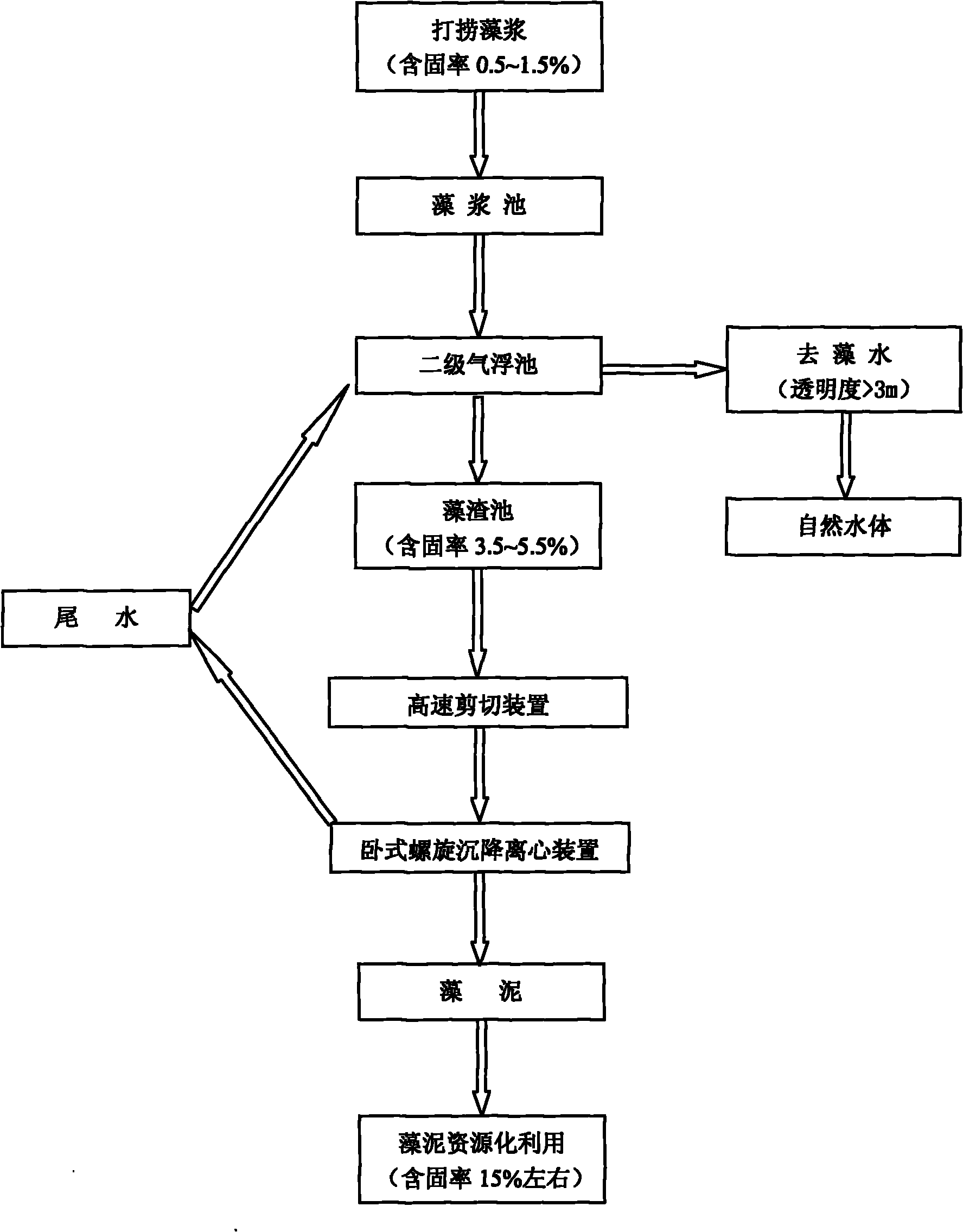

Method used

Image

Examples

example 1

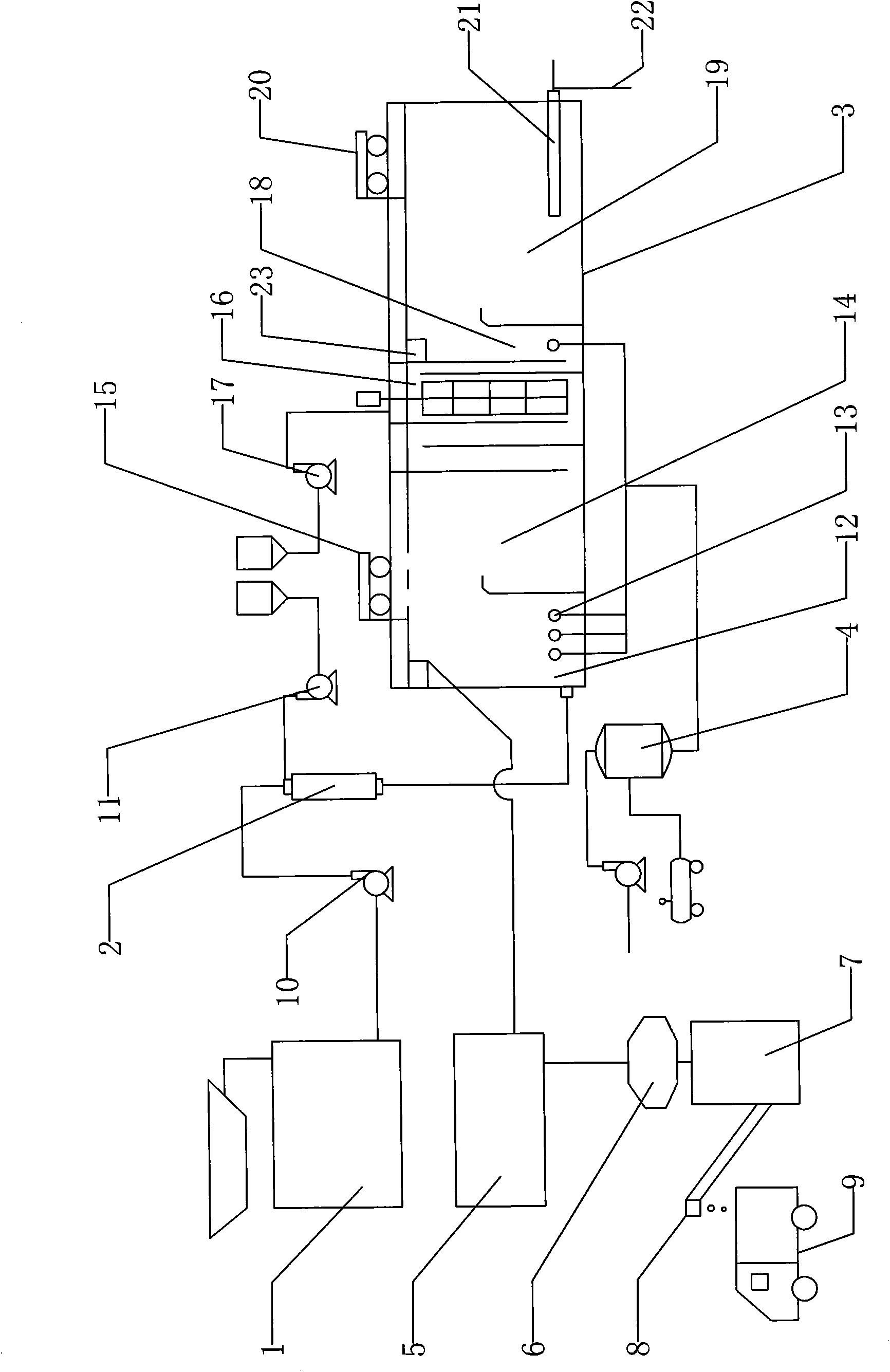

[0029] Example 1, Wuxi Yangwan Algal Water Separation Station:

[0030] In May 2009, an algae water separation station was built in Yangwan near the shore of Shibawan cyanobacteria gathering waters in Wuxi City, Jiangsu Province. The algae-water separation station is designed to process cyanobacteria: 10,000 tons / day, (solid content of algal pulp is 0.5-1.5%), algae removal rate is over 95%; algae pulp pool 7m×8m×3.5m (effective volume 150m 3 ); air flotation pool 4.8m×24.8m×2.8m, 2 sets; pipe mixer DN125×1200mm, 2 sets; pressure dissolved air tank working pressure 2.8kgf / cm 2 ; The gas-solid ratio is 0.02, and the algae residue pool is 4m×6m×3.5m (effective volume 60m 3 ); Horizontal spiral decanter centrifuge, design flow rate 15m 3 / h, 2 sets; the processing effect is as follows:

[0031]Table 1: Pollutant removal effect table

[0032]

[0033] According to the analysis of the above influent and effluent water quality testing results, the actual cyanobacteria removal...

example 2

[0034] Example 2, Wuxi Lvjiang Estuary Algal Water Separation Station:

[0035] In May 2009, an algae-water separation station was built in Lujiangkou, near the shore of the Lujiangkou cyanobacteria gathering waters in Wuxi City, Jiangsu Province. The algae-water separation station is designed to process cyanobacteria: 10,000 tons / day, (solid content of algal pulp is 0.5-1.5%), algae removal rate is over 95%; algae pulp pool 7m×8m×3.5m (effective volume 150m 3 ); air flotation pool 4.8m×24.8m×2.8m; pipeline mixer DN125×1200mm; working pressure of pressure dissolved air tank 2.8kgf / cm 2 ; The gas-solid ratio is 0.015, and the algae residue pool is 4m×6m×3.5m (effective volume 60m 3 ); Horizontal spiral decanter centrifuge, design flow rate 15m 3 / h; the processing effect is as follows:

[0036] Table 2: Pollutant removal effect table

[0037]

example 3

[0038] Example 3, Wuxi Xin'an algal water separation station:

[0039] In May 2009, an algae-water separation station was built in Xin'an near the shore of the cyanobacteria-gathering waters of Xidong Water Plant, Wuxi City, Jiangsu Province. The algae water separation station is designed to process cyanobacteria: 5000 tons / day, (solid content of algae slurry is 0.5-1.5%), algae removal rate is over 95%; algae slurry pool 7m×8m×3.5m (effective volume 150m 3 ); air flotation pool 4.8m×24.8m×2.8m; pipeline mixer DN125×1200mm; working pressure of pressure dissolved air tank 2.8kgf / cm 2 ; The gas-solid ratio is 0.012, and the algae residue pool is 4m×6m×3.5m (effective volume 60m 3 ); Horizontal spiral decanter centrifuge, design flow rate 15m 3 / h; the processing effect is as follows:

[0040] Table 3: Pollutant removal effect table

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com