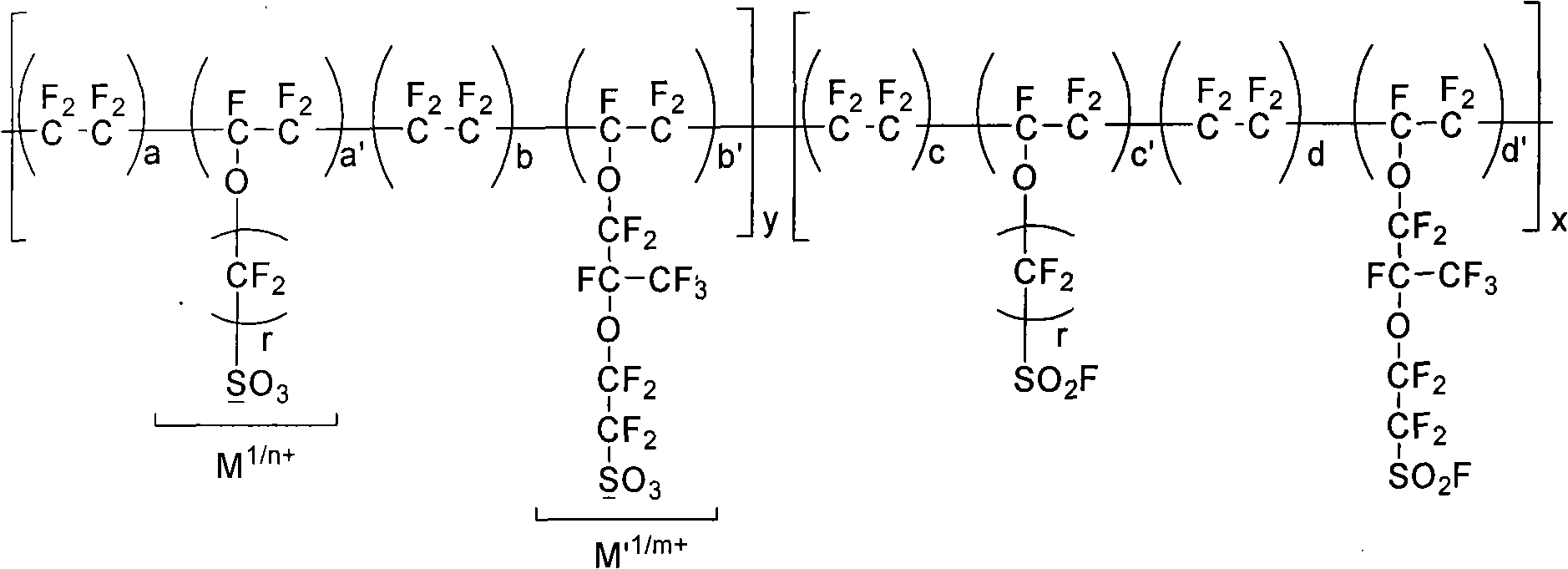

Functional perfluoro resin and preparation method thereof

A functional and fluororesin technology, which is applied in the field of multi-component copolymerized perfluorinated ion exchange resin and its preparation, can solve the problem of insufficient molecular weight of the resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

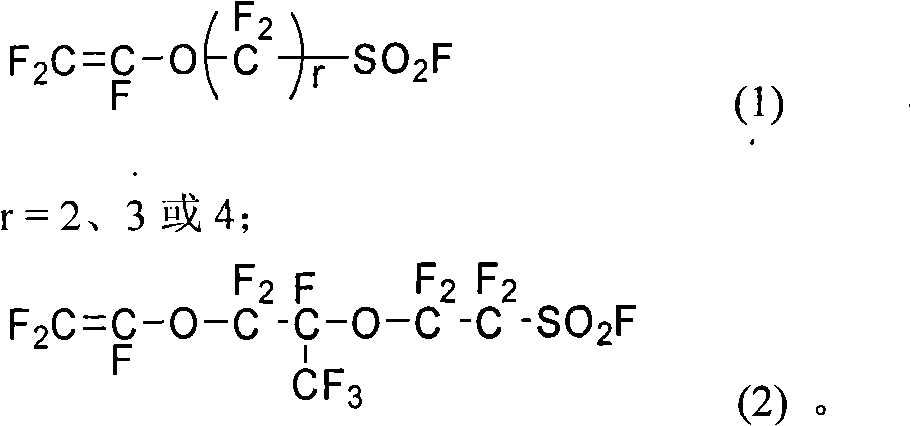

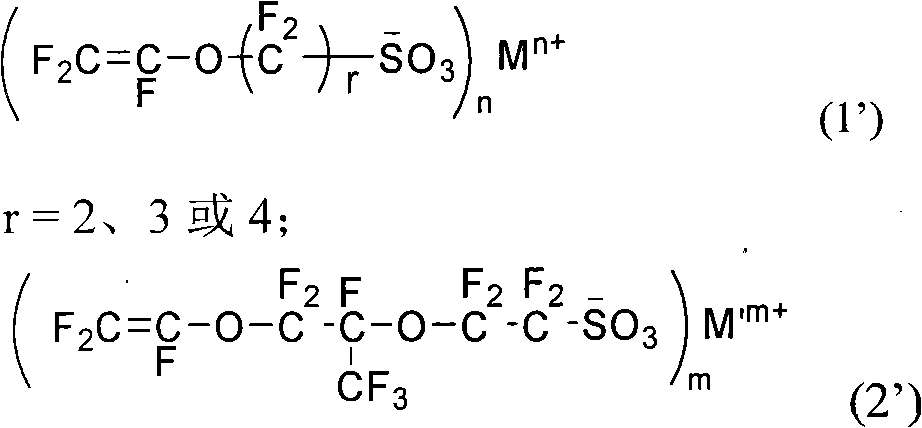

[0034] The preparation method of the functional perfluororesin with sulfonyl fluoride and sulfonate side groups is an emulsion polymerization reaction carried out in the water phase, and the steps are:

[0035] 1), after cleaning the reaction kettle, add pure water, sulfonyl fluoride pendant alkenyl ether and sulfonyl fluoride pendant alkenyl ether, the overall mass percentage concentration of the two sulfonyl fluoride pendant alkenyl ethers in water is 5-50 %, the overall mass percent concentration of the two sulfonate pendant alkenyl ethers in water is 0.5 to 5%;

[0036] 2) Fill the reaction kettle with tetrafluoroethylene monomer through the gas metering tank to a pressure of 2-10MPa;

[0037] 3) The temperature of the reactor is raised to 10-60°C, adding an initiator into the reaction system through a metering pump to initiate the reaction, and continuously adding tetrafluoroethylene monomer and initiator to the reactor to keep the reaction pressure of the reactor at 2-10...

specific Embodiment approach

[0049] The following examples are further illustrations of the present invention, but the present invention is not limited thereto. Unless otherwise specified, the reaction kettles used in each embodiment are all 10L stainless steel high-pressure reaction kettles, and are equipped with temperature sensors, pressure sensors, heating circulation systems, cooling circulation systems, stirring motors, internal cooling water pipes, liquid metering pumps, gas Feed valve, liquid feed valve, material discharge valve in the reactor.

[0050] The perfluoroalkyl initiator used in the synthesis process of the present invention can be prepared according to known techniques in the art, and the recommended preparation method of the present invention can be found in J.Org.Chem., 1982, 47(11):2009-2013.

[0051] Potassium persulfate, ammonium persulfate, N 2 f 2 All gases are available for purchase.

[0052] The comonomer tetrafluoroethylene, sulfonyl fluoride side group vinyl ether monomer...

Embodiment 1

[0053] Embodiment 1, (r=2)

[0054] Reactor is cleaned and adds 5.0L deionized water, 500ml contains 70g cerium sulfonate pendant vinyl ether monomer (1 ') ((F 2 C=CF-O-CF 2 CF 2 -SO 3 - ) 4 Ce 4+ ) and 25g cerium sulfonate pendant vinyl ether monomer (2') ((F 2 C=CF-O-CF 2 -CF(CF 3 )-O-CF 2 CF 2 -SO 3 - )3Ce 3+ ) aqueous solution, start the stirring device, vacuumize and replace with high-purity nitrogen for three times, after the oxygen content in the reactor is tested to be below 1ppm, vacuumize, and add 500g of sulfonyl fluoride pendant alkenyl ether into the reactor through the liquid feed valve Monomer(1)(F 2 C=CF-O-CF 2 -CF 2 -SO 2 F) and 500g sulfonyl fluoride pendant vinyl ether monomer (2) (F 2 C=CF-O-CF 2 -CF(CF 3 )-O-CF 2 CF 2 -SO 2 F) After that, fill the reaction kettle with tetrafluoroethylene monomer to a pressure of 2.3MPa, raise the temperature to 25°C, and add 2.2g perfluorobutyryl compound (CF 3 CF 2 CF 2 CO-OO-CCF 2 CF 2 CF 3 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com