Method for clearing away aflatoxin from crop seeds by utilizing acid electrolyzed functional water

A technology for electro-generating functional water and aflatoxin, which is applied in the fields of application, food science, food preparation, etc., can solve the problems of high processing conditions, high processing cost, difficult production and application, etc., and achieves no hidden safety hazards and low processing costs. , the effect of avoiding secondary pollution and toxin residue problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of acidic electrogenerated functional water

[0028] A. Preparation of strongly acidic electrogenerated functional water:

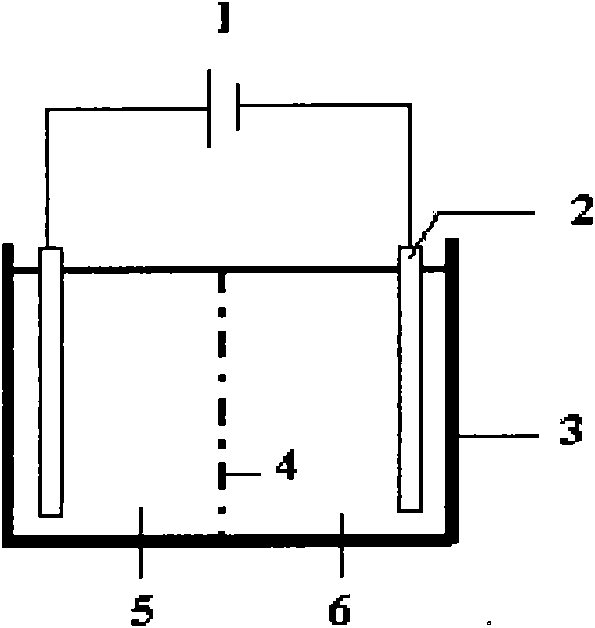

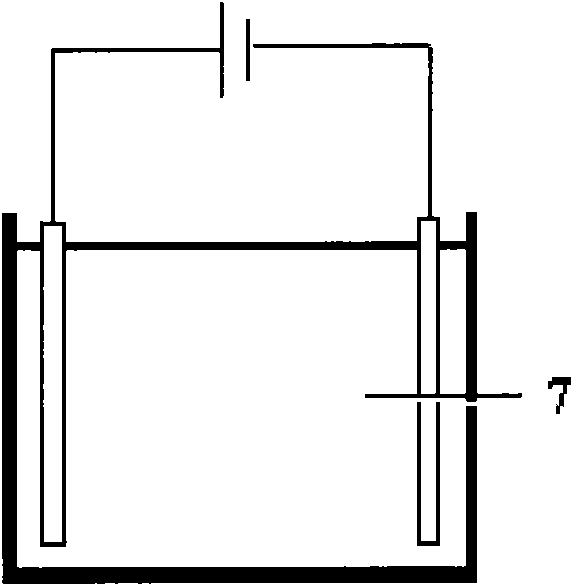

[0029] (1) Sodium chloride is dissolved in drinking water at a ratio of 0.2% by weight, fully stirred evenly, and then placed in figure 1 In the two electrolyzers of the strong acidic electric functional water generator shown;

[0030] (2) When the voltage is 30V, the current is 2.0A, the electrode distance is 12mm, and the plate area is 108cm 2 The electrolysis reaction was carried out for 15 minutes; that is, strong acid electrogenerated functional water was obtained in the anode electrolyzer, and alkaline electrogenerated functional water was obtained in the cathode electrolyzer. Strongly acidic electro-generated functional water is pH=2.50±0.77, ORP=1097±28mV, and the content of available chlorine is 100.5±3.9mg / L; the obtained alkaline electro-generated functional water is pH=11.46±0.11, ORP=-851.8± 45.3mV.

[0031] B...

Embodiment 2

[0034] Example 2 Test of the removal effect of acidic electrogenic functional water on aflatoxin in peanut seeds

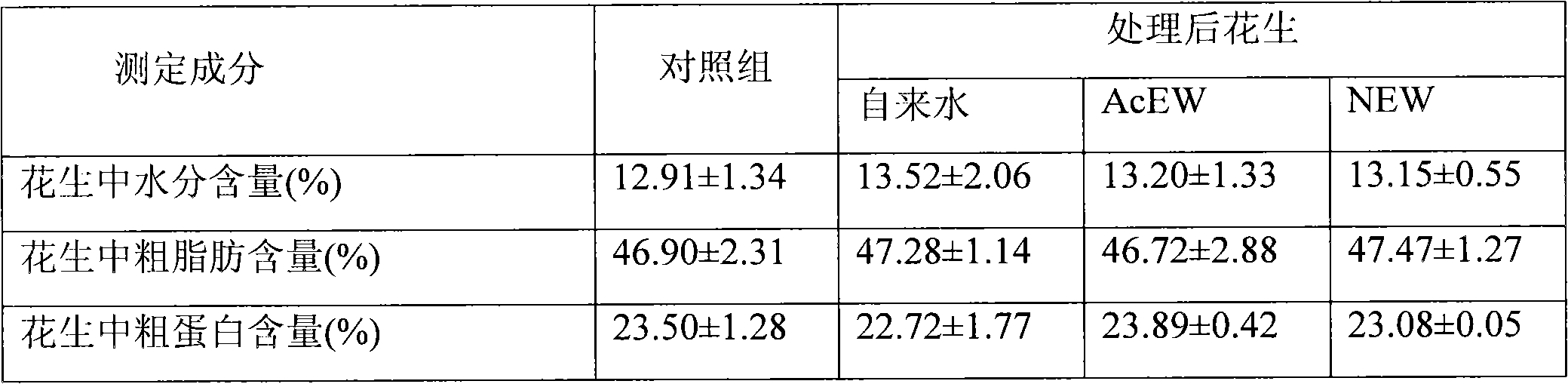

[0035] (1) Test material: a, the processing of peanut grain: get peanut 5kg, store 30 days under the environment of temperature 30 ± 2 ℃, relative humidity 90 ± 5%, naturally go moldy; b, the prepared by embodiment 1 AcEW and NEW with an available chlorine concentration of 100 mg / L were adjusted to AcEW and NEW with an available chlorine concentration of 60 mg / L with distilled water, respectively. Strong alkaline electrogenic functional water (hereinafter referred to as AlEW) pH=11.62±0.22, ORP=-872.0±31.1mV, tap water (control) pH=7.67±0.05, ORP=535.9±93.0.

[0036] (2) Test method: Weigh 20g of processed peanuts for each portion, place them in conical flasks, and add tap water, AlEW and available chlorine to different conical flasks with a ratio of liquid to material mass ratio of 5:1. AcEW and NEW with a concentration of 60mg / L were shaken at 45°C for 15 minut...

Embodiment 3

[0039] Example 3 Process Test of Acidic Electric Functional Water for Removing Aflatoxins

[0040] This example is a test of the toxin removal effect of electrogenic functional water on aflatoxin-contaminated peanuts under different available chlorine concentrations, different cleaning methods, different liquid-to-solid ratios, different treatment times and different treatment temperatures. details as follows:

[0041] (1) Test material: the mildewed peanut material prepared in step (1) of Example 2.

[0042] (2) various waters that are used to process moldy peanuts in the test: the AcEW and NEW that the available chlorine concentration prepared in Example 1 is 100mg / L are adjusted to be 20mg / L, 40mg / L, 40mg / L, 60mg / L and 80mg / L AcEW and NEW.

[0043] (3) Test method: ① Test of different available chlorine concentrations, weigh 20g of moldy peanuts for each portion, place them in conical flasks respectively, and add available chlorine concentrations of 20mg / L and 40mg respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com