Digital signal processor (DSP) embedded controller for electric dust-removing three-phase high-voltage direct-current power supply

A high-voltage DC power supply and embedded controller technology, applied in power supply technology, electrostatic separation, etc., can solve the problems of difficult to meet increasingly stringent environmental protection requirements, difficult to optimize the overall electrostatic precipitator system, and high flashover discharge intensity on the secondary side , to improve the ability to collect and process data in real time, improve the anti-interference ability of the system, and reduce the complexity of task management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing, the present invention is further described:

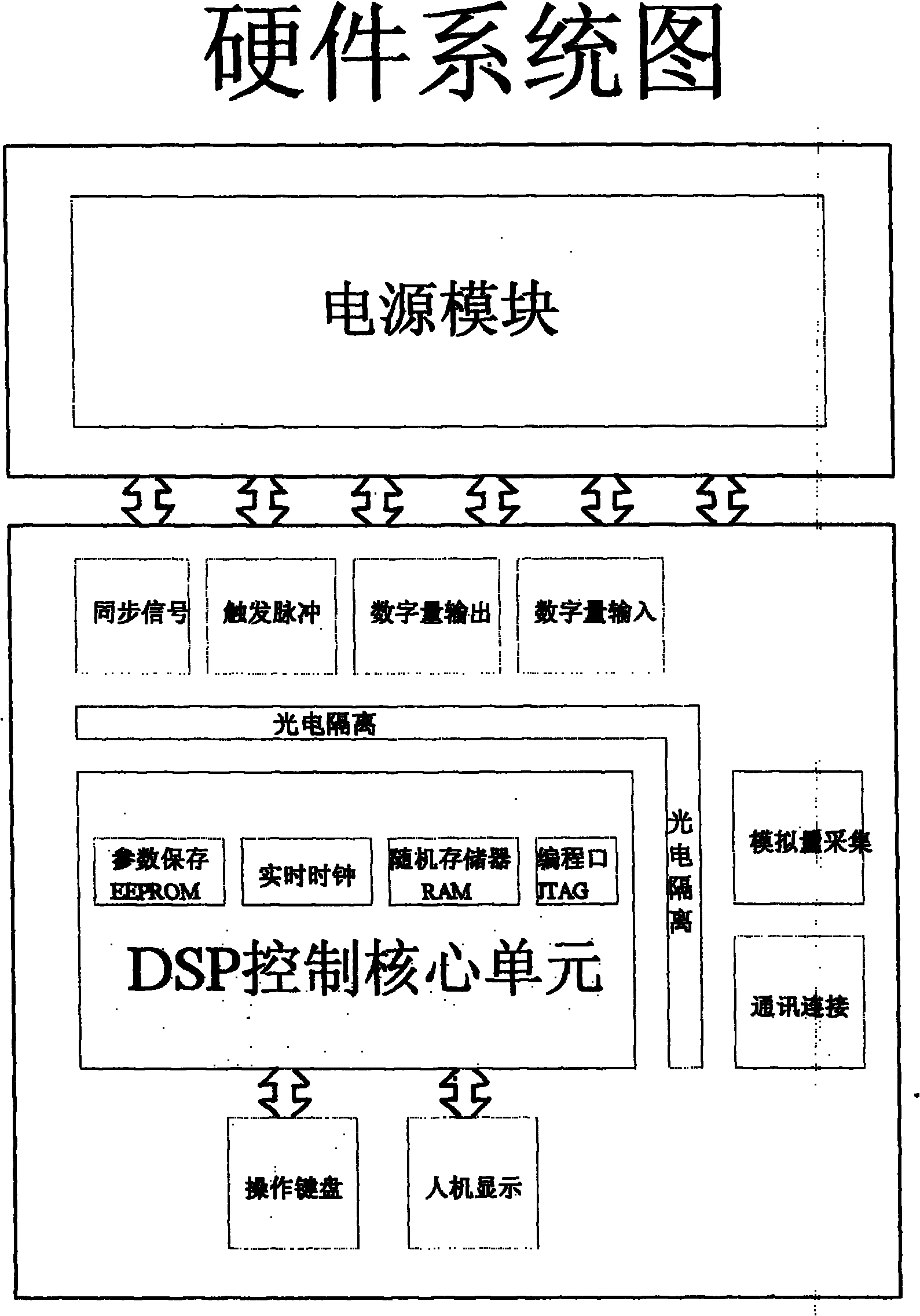

[0066] hardware system

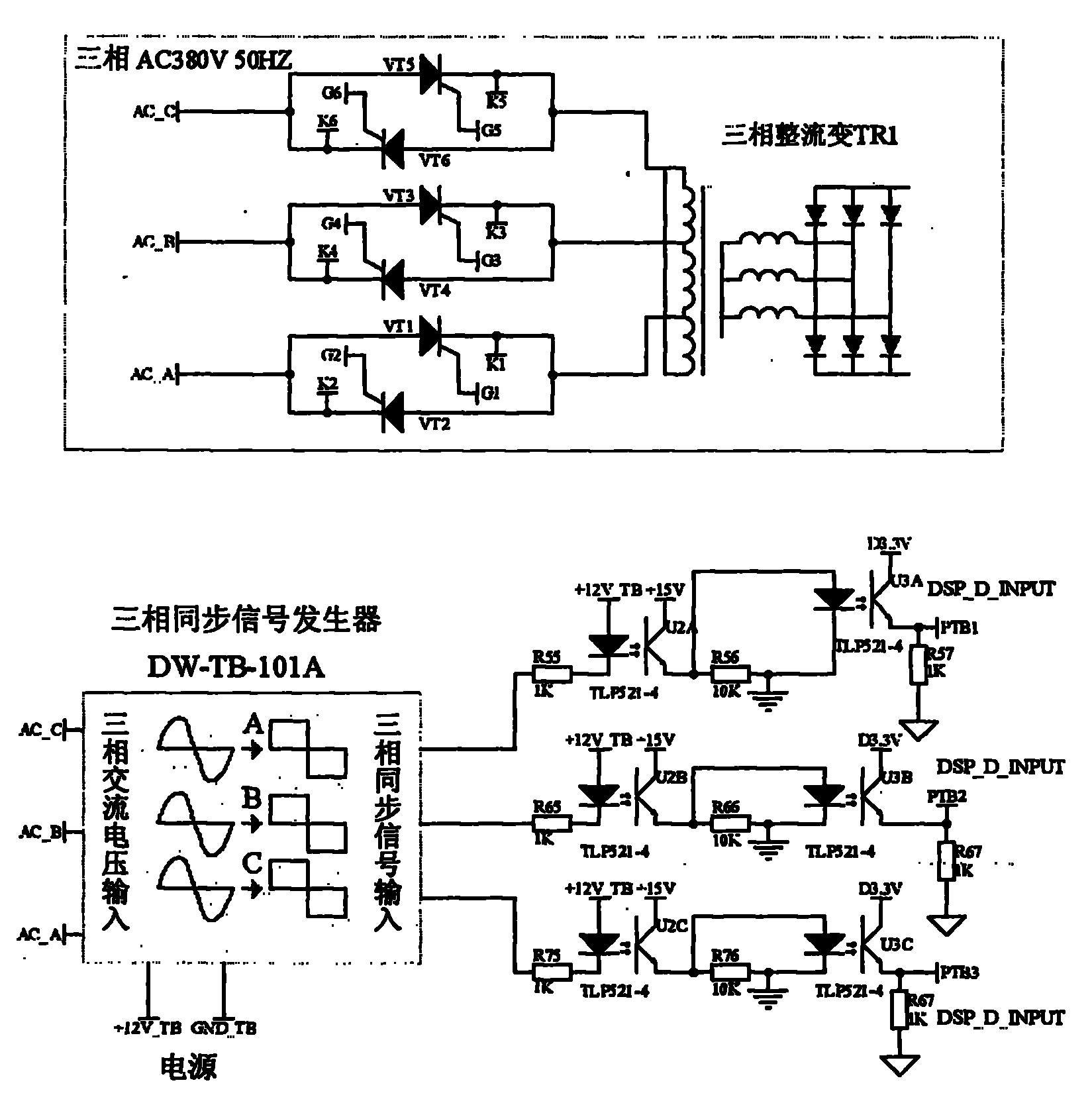

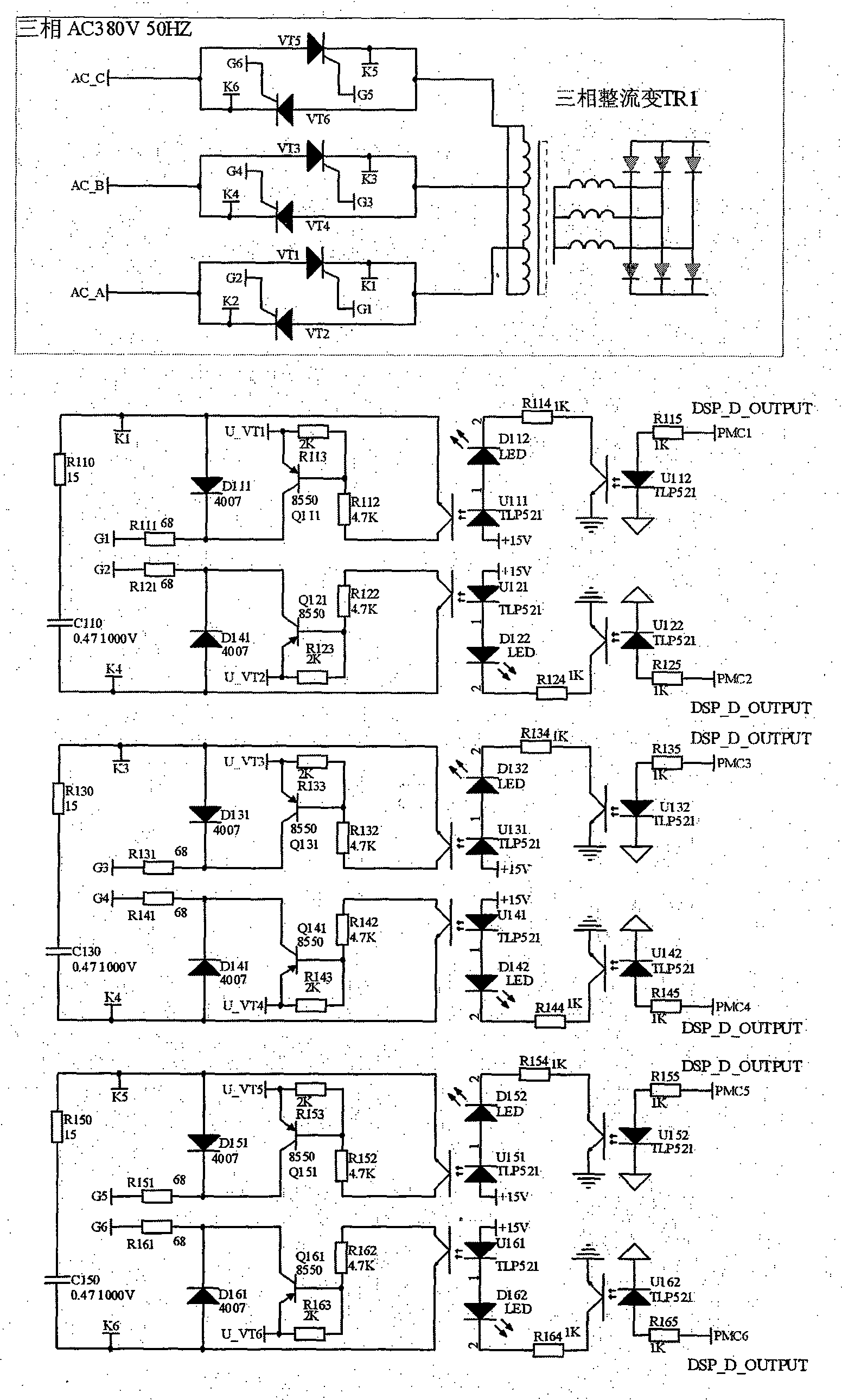

[0067] see hardware system figure 1 Shown: The hardware system of the ESP three-phase high-voltage DC power supply DSP embedded controller includes DSP control core unit 1, synchronization signal 2, trigger pulse 3, digital output 4, digital input 5, analog acquisition 6, communication Connection 7, man-machine display 8, operation keyboard 9, power module 10, photoelectric isolation 11. The system adopts a modular design, and the peripheral digital input and output, analog signal acquisition, and communication connections all adopt a photoelectric isolation scheme, which prevents the peripheral interface circuit from interfering with the control core unit and improves the stability of the system. The man-machine display interface and operation keyboard are directly connected with the control core unit of DSP. Among them, the photoelectric isolation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com