Soil conditioner, preparation method and application thereof

A soil conditioner and reaction technology, applied in the direction of soil conditioning materials, applications, chemical instruments and methods, etc., can solve the problem of not considering the utilization of sludge, and the method and process of making high-efficiency fertilizer from aquatic organisms and sludge, adding The ammonia process is not involved in other issues, to achieve the effect of promoting normal growth and development, improving the soil microenvironment, and stimulating a large number of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

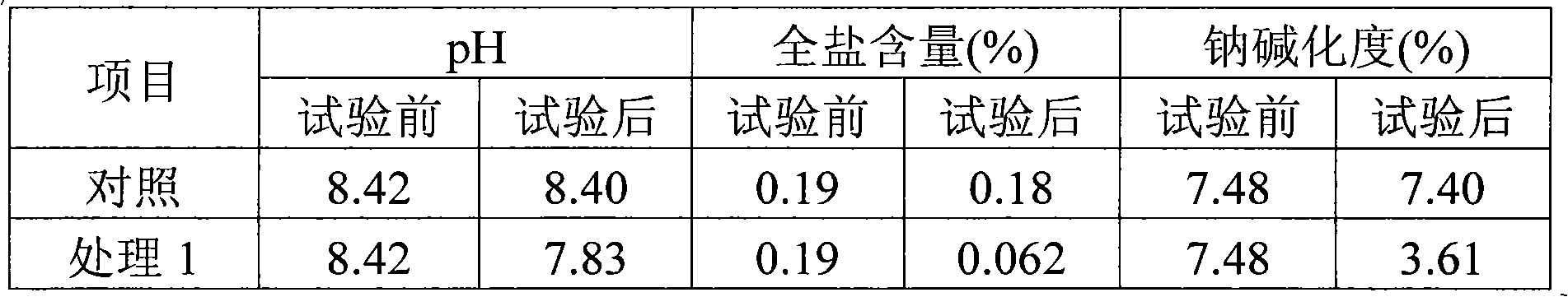

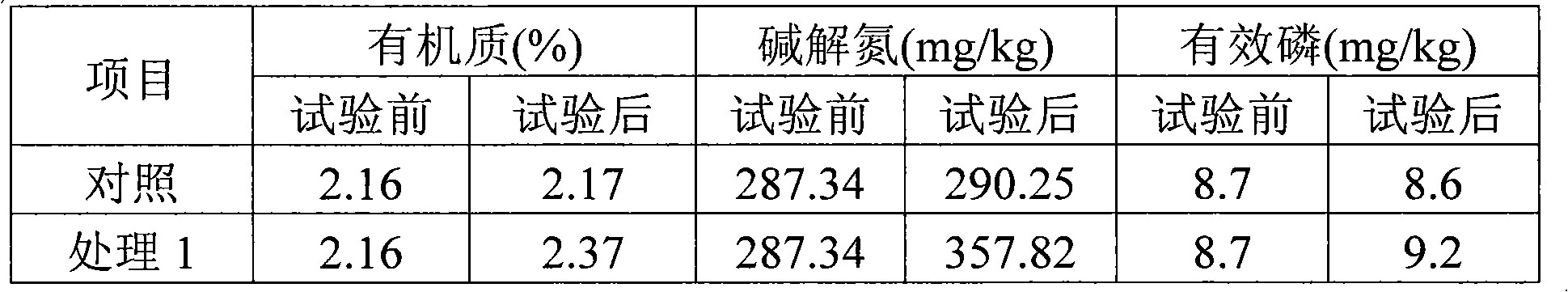

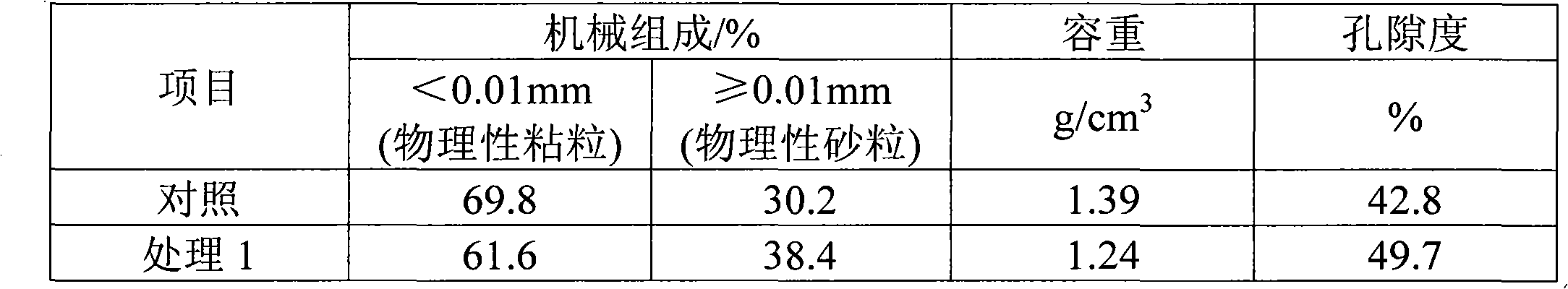

Embodiment 1

[0032] A soil conditioner, which can be used for tree planting in saline-alkali soil, comprises the following components on a dry basis:

[0033] Ammonified sludge 85%, polyamino acid 4%, auxiliary materials 11%.

[0034] Preparation:

[0035] Raw material (according to the percentage of conditioner gross weight):

[0036] Sludge 85%, polymerized amino acid 4%, animal and plant residue 3%, phosphogypsum 3%, fly ash 5%.

[0037] preparation:

[0038] 1) Add ammonia to sludge and organic materials, and obtain ammoniated sludge through the following steps.

[0039] Step 1: Send the sludge that has been sorted to remove metal, plastic, glass, sand, and chopped animal and plant residues into the hydrolysis tank. At 80°C, the pressure is 0.8MPa and the dosage is The concentration of 0.5% of the basis weight is 10% dilute sulfuric acid, and the hydrolysis reaction is completed after 2 hours;

[0040]Step 2: The material that has completed the hydrolysis reaction of step 1 is pum...

Embodiment 2

[0052] A soil conditioner, which can be used in the production of tea leaves in clayey soils, and consists of the following components on a dry basis:

[0053] 75% of ammoniated sludge, 8% of polymerized amino acid, and 17% of auxiliary materials.

[0054] Preparation:

[0055] Raw material (according to the percentage of conditioner gross weight):

[0056] Sludge 75%, polymerized amino acid 8%, animal and plant residue 7%, humic acid 3%, medical stone 7%.

[0057] preparation:

[0058] 1) Add ammonia to sludge and organic materials, and obtain ammoniated sludge through the following steps.

[0059] Step 1: Send the sludge that has been sorted to remove metal, plastic, glass, sand, and chopped animal and plant residues into the hydrolysis tank. At 100 ° C, the pressure is 1.0 MPa and the amount is The concentration of 1% of the basis weight is 10% dilute hydrochloric acid to complete the hydrolysis reaction after 1.5 hours;

[0060] Step 2: The material that has completed...

Embodiment 3

[0070] A soil conditioner, which can be used for rice planting in cold-soaked fields, and contains the following components on a dry basis:

[0071] 80% of ammoniated sludge, 1% of polymerized amino acid, and 19% of auxiliary materials.

[0072] Preparation:

[0073] Raw material (according to the percentage of conditioner gross weight):

[0074] 80% of sludge, 1% of polymerized amino acid, 4% of animal and plant residues, 4% of peat, 8% of superphosphate, and 2% of bentonite.

[0075] preparation:

[0076] 1) Add ammonia to sludge and organic materials, and obtain ammoniated sludge through the following steps.

[0077] Step 1: Send the sludge that has been sorted to remove metal, plastic, glass, sand, and chopped animal and plant residues into the hydrolysis tank. At 180°C, the pressure is 1.2MPa and the amount is The concentration of 2% of the basis weight is that 15% acetic acid acts for 2 hours to complete the hydrolysis reaction;

[0078] Step 2: The material that ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com