Method for preparing high-cleanness fuel oil from intermediate-temperature and low-temperature coal tar

A technology for low-temperature coal tar and fuel oil, which is applied in the direction of tar processing through selective solvent extraction, can solve the problems of affecting the effect of hydrogenation catalysis, high energy consumption, and inability to produce condensed aromatic hydrocarbons, preventing poisoning, prolonging The effect of running cycle and avoiding bed clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

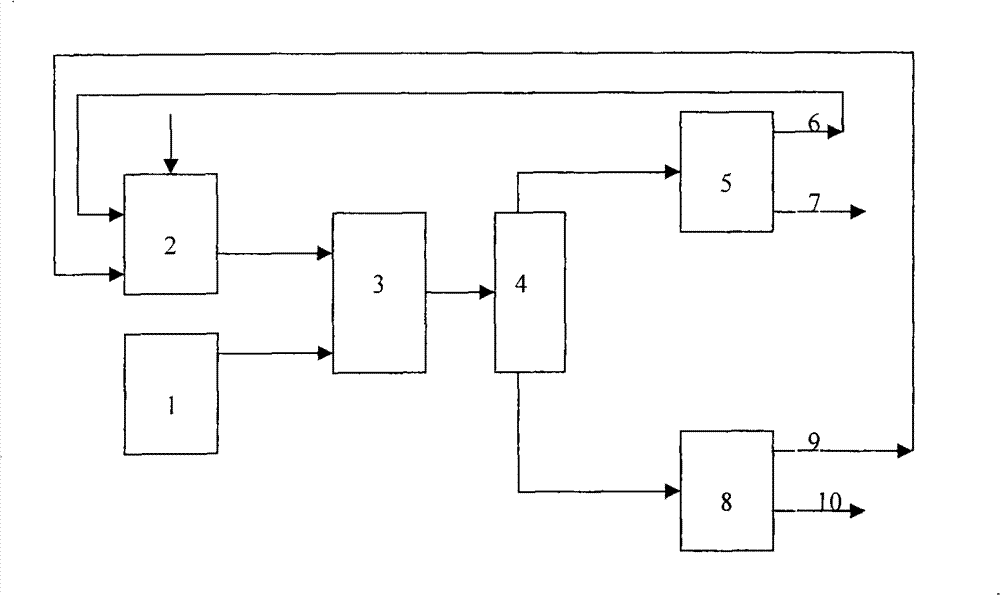

Method used

Image

Examples

Embodiment 1

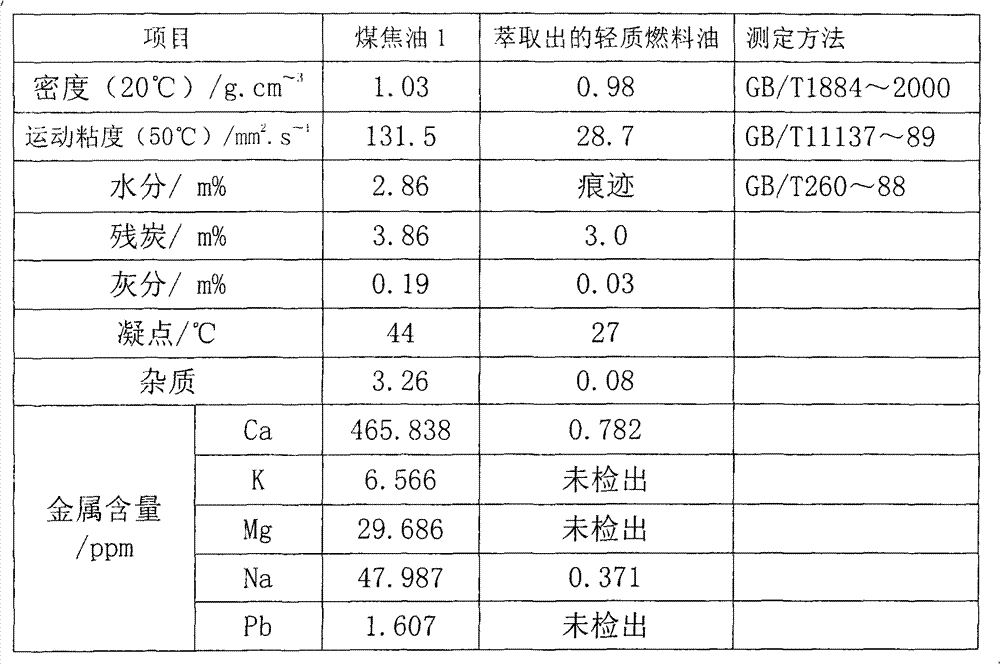

[0045] The coal tar 1 of this example is a medium temperature coal tar, and its properties are shown in Table 1.

[0046] Its processing steps are as follows:

[0047] 1. Stir and mix the extraction

[0048] The extraction agent is industrial n-hexane, which is put into a solvent tank for use;

[0049] Use a filter to remove impurities from the coal tar 1, then pour the coal tar and the prepared extractant into a mixing tank at a volume ratio of 2:3, and stir and mix with a mixer for 40 minutes; the extraction temperature is 45°C.

[0050] 2. Static separation

[0051] Pour the stirred mixed liquid into the static tank, let it stand for separation for 50 minutes, pump the stratified upper layer light liquid into the light liquid buffer tank; pump the lower layer heavy liquid into the heavy liquid buffer tank.

[0052] 3. Recovery of light liquid extraction solvent

[0053] The light liquid is pumped into the evaporator, heated to 115°C with steam, the solvent is evaporated...

Embodiment 2

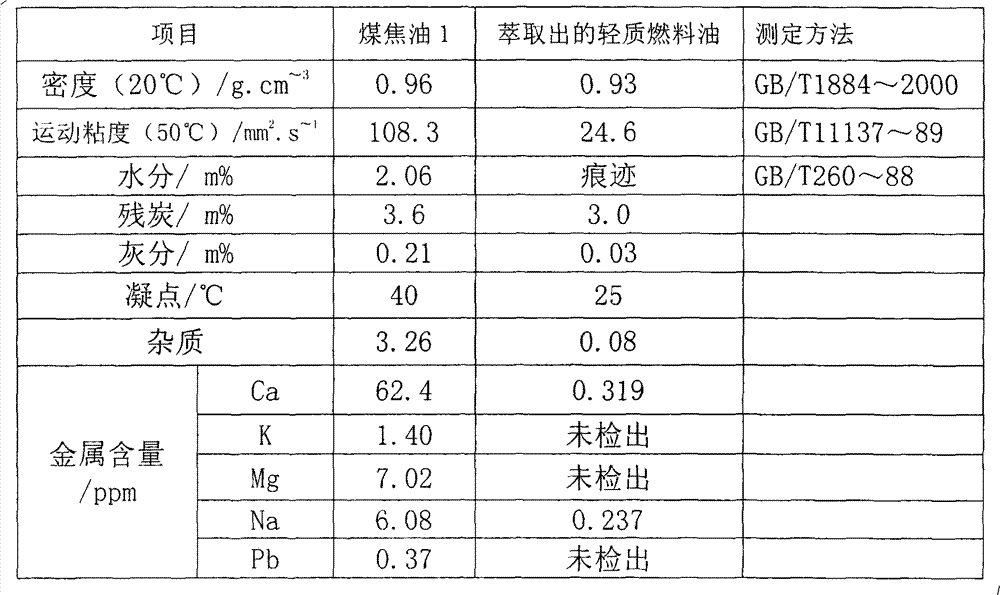

[0061] The coal tar 2 of this example is a low-temperature coal tar, and its properties are shown in Table 2;

[0062] Its processing steps are as follows:

[0063] 1. Stir and mix the extraction

[0064] The extraction solvent is chemical solvent 6# solvent oil, which is put into the solvent tank for use;

[0065] Use a filter to remove impurities from the coal tar 2, then pour the coal tar and the prepared extractant into a mixing tank at a ratio of 1:1 by volume, and stir and mix with a mixer for 30 minutes; the extraction temperature is 45°C.

[0066] 2. Static separation

[0067] Pour the stirred mixed liquid into the static tank, stand and separate for 50 minutes, pump the layered upper layer light liquid into the light liquid buffer tank; the lower layer heavy liquid into the heavy liquid buffer tank.

[0068] 3. Recovery of light liquid extraction solvent

[0069] Pump the light liquid into the evaporator, heat it with steam to 105°C, evaporate the solvent and reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com