Method for producing bacterial cellulose with wheat straws/straws

A bacterial cellulose and wheat straw technology, applied in the field of bacterial cellulose preparation, can solve the problems of polluting the environment, unutilized rice straw, wasting resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

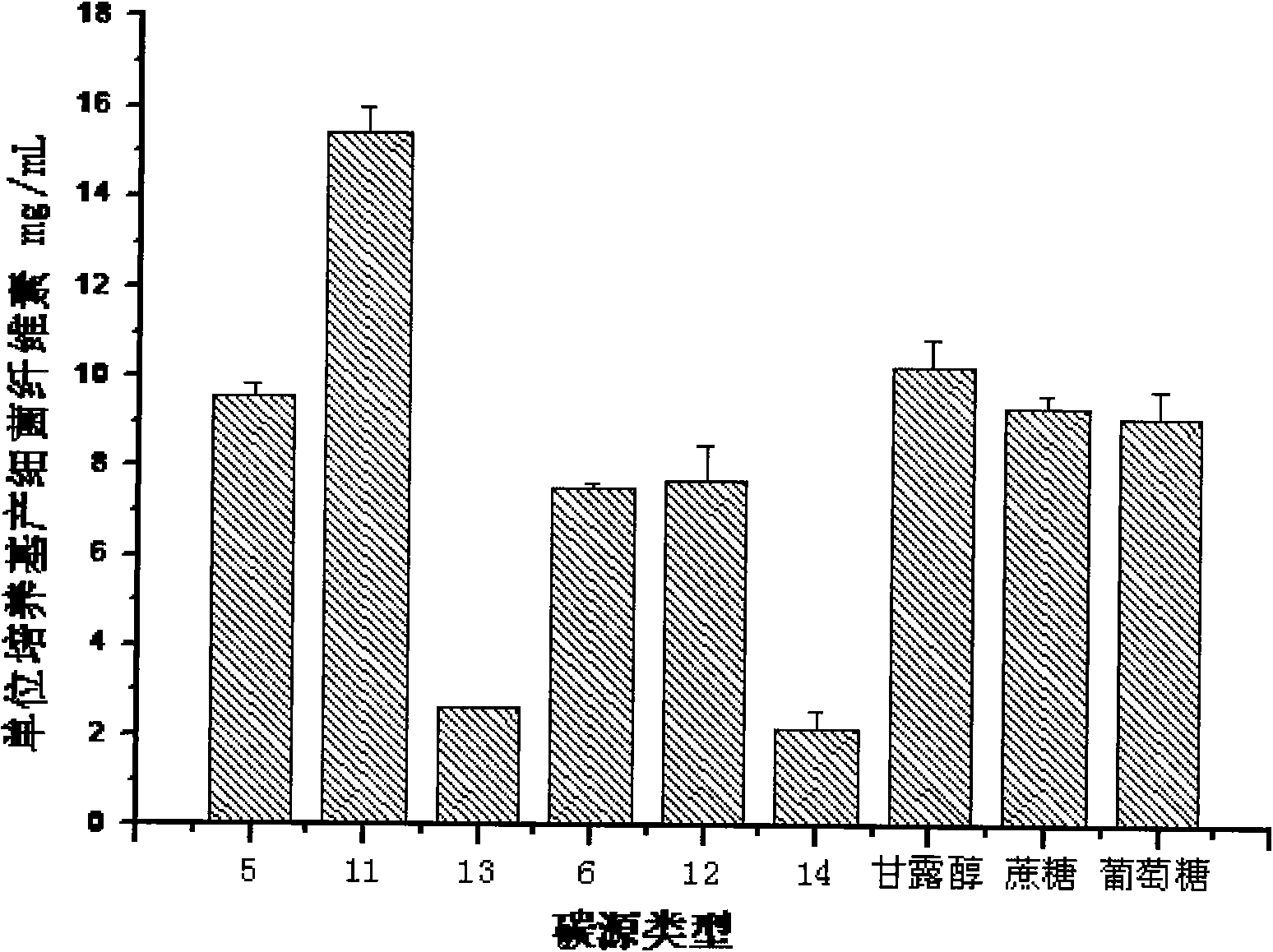

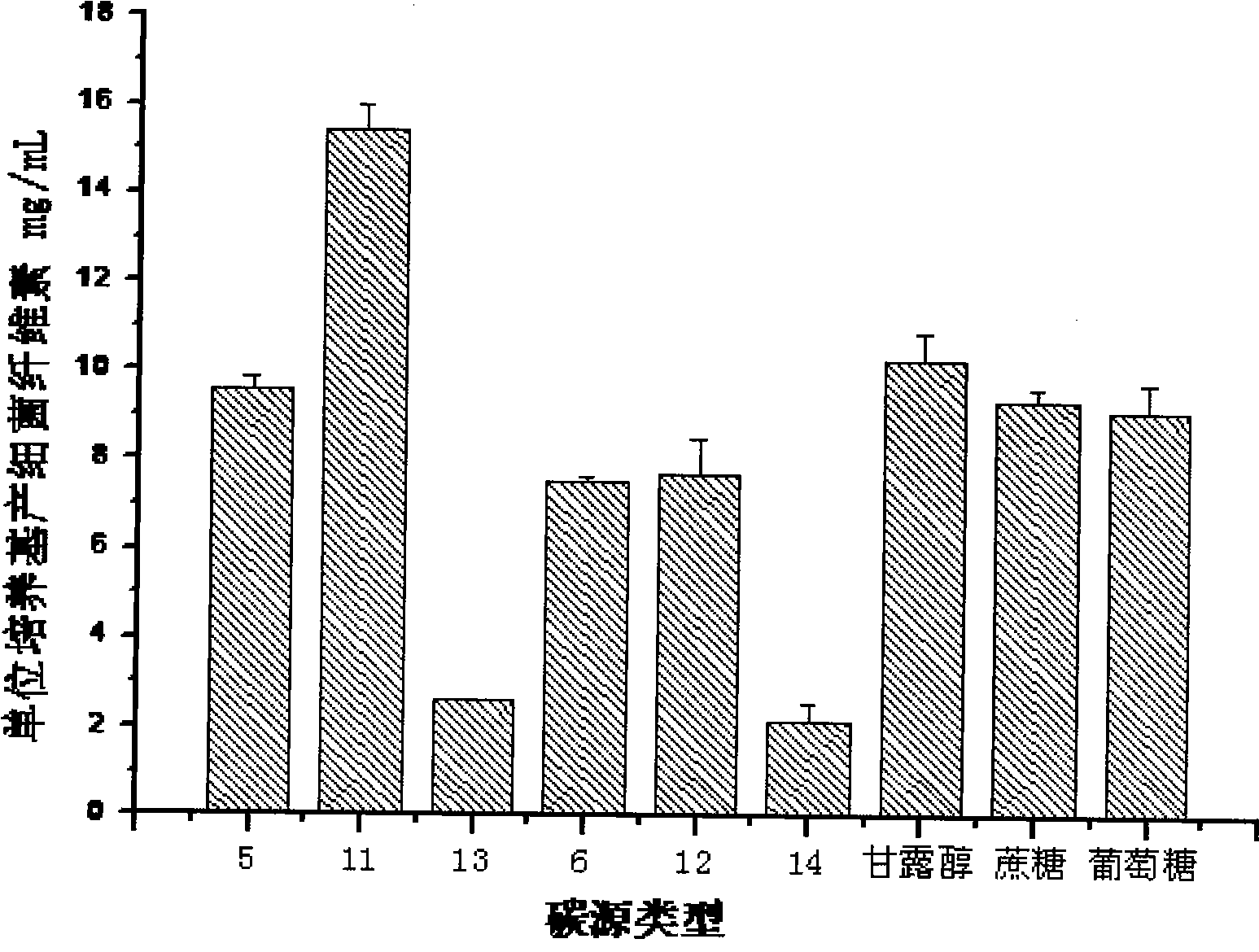

Image

Examples

Embodiment 1

[0071] Wheat straw is first ground with a plant pulverizer, then soaked overnight (12-24h) with dilute sulfuric acid (3%, w / v) in a reactor at a solid / liquid ratio of 1:6 between the straw and dilute acid solution, Then react at a temperature of 121° C. for 60 minutes, then separate the straw residue and acid solution by suction filtration, collect the hydrolyzate, and refrigerate at 4° C. for later use.

[0072] Add NaOH to adjust the pH value of the hydrolyzed liquid to about 10, filter the precipitate with filter paper to obtain the treated hydrolyzed liquid, and then fine-tune the pH value to 10.0. Then seal it with a film, place it in a 30°C water bath for 12-24 overnight, and finally adjust the pH value of the hydrolyzate to 5.0 with dilute acid. Then add 2% (mass percentage) activated carbon, stir (at room temperature for 5-10min), filter out the activated carbon with filter paper to obtain detoxified hydrolyzed clear liquid, and fine-tune the pH value to 5.5 with dilut...

Embodiment 2

[0074] Wheat straw is first ground with a plant grinder, and then soaked overnight (12-24h) in a reactor with dilute hydrochloric acid (1%, w / v) at a solid / liquid ratio of 1:10 straw to dilute acid solution, Then react at a temperature of 121° C. for 75 minutes, then separate the straw residue and acid solution by suction filtration, collect the hydrolyzate, and refrigerate at 4° C. for later use.

[0075] Add Ca(OH) 2 Adjust the pH value of the hydrolyzed liquid to about 10, filter out the precipitate with filter paper to obtain the treated hydrolyzed liquid, and then fine-tune the pH value to 10.0. Then seal it with a film, place it in a 40°C water bath for 12-24 overnight, and finally adjust the pH value of the hydrolyzate to 5.0 with dilute acid. Then add 2% (mass percentage) activated carbon, stir (at room temperature for 5-10min), filter out the activated carbon with filter paper to obtain detoxified hydrolyzed clear liquid, and fine-tune the pH value to 5.5 with dilute...

Embodiment 3

[0077] Wheat straw is first ground with a plant pulverizer, and then soaked overnight (12-24h) with dilute sulfuric acid (2%, w / v) in a reactor with a solid / liquid ratio of 1:15 straw to dilute acid solution, Then react at a temperature of 100° C. for 80 minutes, then separate the straw residue and acid solution by suction filtration, collect the hydrolyzate, and refrigerate at 4° C. for later use.

[0078] Add 25% ammonia water to adjust the pH value of the hydrolyzed liquid to 10, filter out the precipitate with filter paper to obtain the treated hydrolyzed liquid, and fine-tune the pH value to 10. Then seal it with a film, place it in a 25°C water bath to react overnight, and finally adjust the pH value of the hydrolyzate to 5.0 with dilute acid. Then add 2% (mass percentage) activated carbon, stir (at room temperature for 5-10min), filter out the activated carbon with filter paper to obtain detoxified hydrolyzed clear liquid, and fine-tune the pH value to 5.5 with dilute s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com