Production method of bamboo fiber

A technology of bamboo fibrils and a production method, applied in the field of fiber production, can solve the problems of production cost, the production continuity of production steps is not effectively solved, etc., and achieves the effects of good hygroscopicity, environmental protection and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

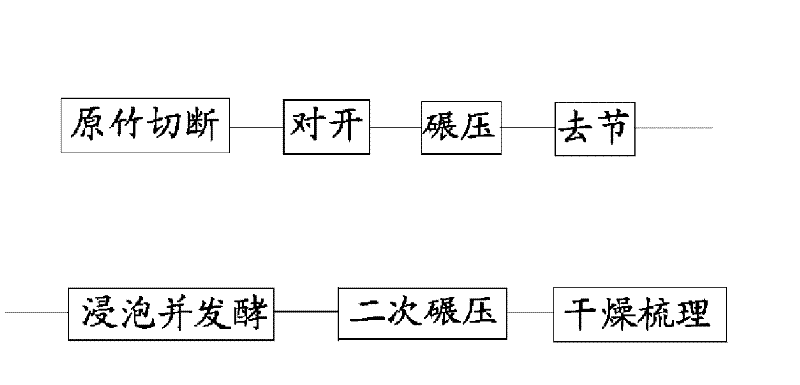

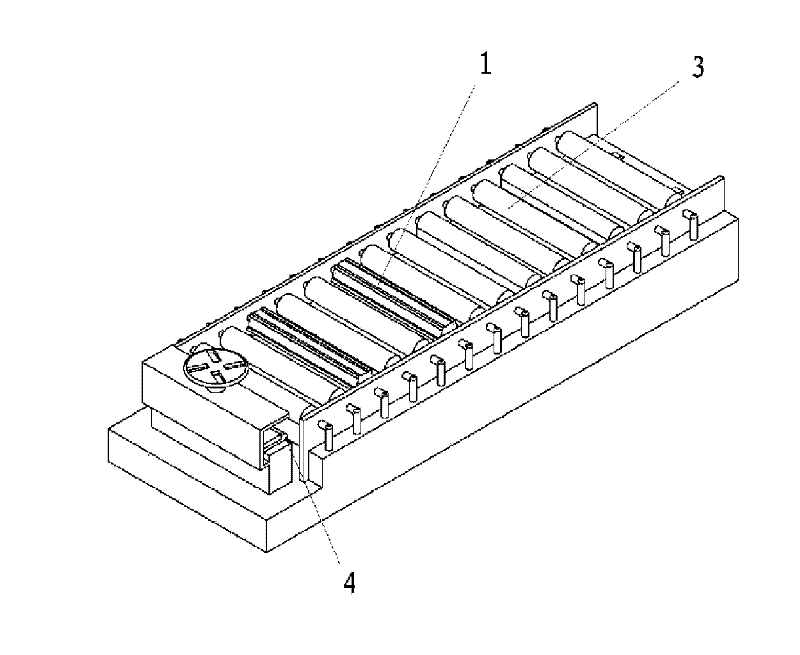

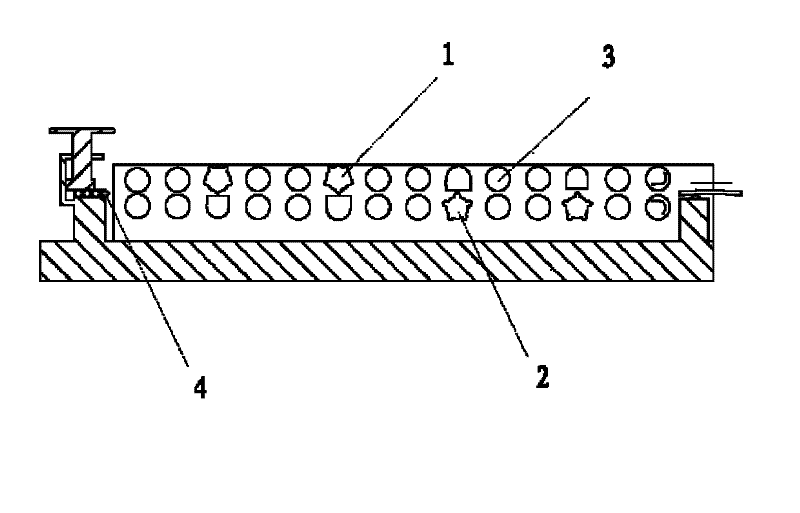

[0051] Such as figure 1Shown, the preparation method of bamboo fiber comprises crude bamboo fiber and refined bamboo fiber, and described crude bamboo fiber comprises that original bamboo is cut off and makes bamboo hemp, it is characterized in that: after the original bamboo cutting step, the original bamboo is split, The split raw bamboo is rolled step by step with a pressing roller, and the inner and outer nodes of the raw bamboo are removed while rolling; Refining the raw bamboo fiber is: soaking and fermenting the bamboo slices obtained after slicing, then rolling for the second time, and finally drying and combing. Both soaking rolling and drying carding are techniques well known to those skilled in the art. Described fermentation is to add the bamboo chip of fragmentation in reaction tank and add the enzyme preparation and purified water of " ligninase: pectinase: hemicellulase = 1:1:2 " simultaneously, and described enzyme preparation is in fermented liquid The conte...

Embodiment 2

[0054] The only difference from Example 1 is that the fermentation conditions are different: the content of the enzyme preparation in the fermentation broth is 50mg / ml, and the reaction temperature is controlled at 50°C, pH8.0, the pressure is normal pressure, and the reaction time is 24h .

Embodiment 3

[0056] The only difference from Example 1 is that the fermentation conditions are different: the content of the enzyme preparation in the fermentation broth is 15mg / ml, and the reaction temperature is controlled at 35°C, pH8.0, the pressure is normal pressure, and the reaction time is 36h .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com