Inverse epitaxial wafer preparation method

A technology of epitaxial wafers and epitaxial layers, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problem of small expansion resistance surface at PN junction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

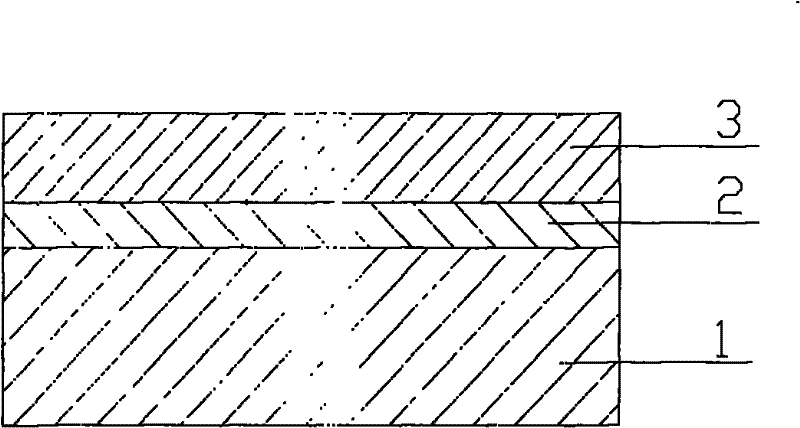

Image

Examples

Embodiment 1

[0019] 1) Pass hydrogen through the monolithic furnace, place the P-type substrate silicon wafer into the monolithic furnace with a manipulator at 800-950°C, raise the temperature to 1140°C, and the hydrogen flow rate is 20L / min;

[0020] 2) Baking to remove the oxide layer, the time is 1min, the hydrogen flow rate is 20L / min;

[0021] 3) Conduct chemical vapor phase polishing with hydrogen chloride for 1 minute, the flow rate of hydrogen chloride is 0.3L / min, and the flow rate of hydrogen gas is 20L / min;

[0022] 4) Raise the temperature of the single-chip furnace to 1170°C, and increase the hydrogen flow rate to 100L / min;

[0023] 5) The intrinsic barrier layer is grown by trichlorosilane, the trichlorosilane flow rate: 3L / min, and the growth time is 10 seconds; the intrinsic barrier layer produced is single crystal intrinsic silicon;

[0024] 6) Turn off the trichlorosilane, keep the temperature within the range of 1170°C, and expel the gas for 50 seconds at a hydrogen flo...

Embodiment 2

[0029] 1) Pass hydrogen through the single-chip furnace, place the P-type substrate silicon wafer into the single-chip furnace with a robot at 950°C, raise the temperature to 1150°C, and the hydrogen flow rate is 80L / min;

[0030] 2) Baking to remove the oxide layer, the time is 3min, the hydrogen flow rate is 80L / min;

[0031] 3) Conduct chemical vapor phase polishing with hydrogen chloride for 1 minute, hydrogen chloride flow rate 1L / min, hydrogen flow rate 80L / min;

[0032] 4) Raise the temperature of the single-chip furnace to 1210°C, and increase the hydrogen flow rate to 200L / min;

[0033] 5) The intrinsic barrier layer is grown by trichlorosilane, the trichlorosilane flow rate: 8L / min, and the growth time is 60 seconds; the intrinsic barrier layer produced is single crystal intrinsic silicon;

[0034] 6) Turn off the trichlorosilane, keep the temperature within the range of 1210°C, and catch the gas for 120 seconds at a hydrogen flow rate of 200L / min;

[0035] 7) Redu...

Embodiment 3

[0039] 1) Pass hydrogen through the single-chip furnace, place the P-type substrate silicon wafer into the single-chip furnace with a robot at 900°C, raise the temperature to 1145°C, and the hydrogen flow rate is 60L / min;

[0040] 2) Baking to remove the oxide layer, the time is 2min, the hydrogen flow rate is 60L / min;

[0041] 3) Perform chemical vapor phase polishing with hydrogen chloride for 1 minute, the flow rate of hydrogen chloride is 0.7L / min, and the flow rate of hydrogen gas is 60L / min;

[0042] 4) Raise the temperature of the single-chip furnace to 1200°C, and increase the hydrogen flow rate to 150L / min;

[0043] 5) The intrinsic barrier layer is grown by trichlorosilane, the flow rate of trichlorosilane is 6L / min, and the growth time is 40 seconds; the intrinsic barrier layer produced is single crystal intrinsic silicon;

[0044] 6) Turn off the trichlorosilane, keep the temperature within the range of 1200°C, and expel the gas for 80 seconds at a hydrogen flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com