Method for preparing NbVO5 powder with coprecipitation method

A co-precipitation method and powder technology, applied in chemical instruments and methods, inorganic chemistry, niobium compounds, etc., can solve the problems of difficult synthesis, harsh experimental conditions, long reaction cycle, etc., and achieve simple synthesis process, easy operation and industrialization , the effect of short experimental period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Prepare solution A (Nb 2 o 5 solution): 1 g of Nb 2 o 5 Added to 50 ml of sulfuric acid, the temperature was maintained at 180 ° C, and kept stirring until Nb 2 o 5 All dissolved (about 2 hours). Inject the above solution into deionized water to precipitate Nb 2 o 5 ·nH 2 O was precipitated as flocculents and washed several times with deionized water, and the Nb 2 o 5 ·nH 2 The O precipitate was added to deionized water, and 3.794 g of C 2 h 2 o 4 2H 2 O, with constant stirring on a magnetic stirrer until Nb 2 o 5 ·nH 2 O is completely dissolved to make solution A.

[0014] Prepare Solution B: (NH 3 VO 4 solution): 0.8802 g of NH 3 VO 4 Add to 50 ml of deionized water, maintain the temperature at 50 °C, and keep stirring until Nb 2 o 5 All dissolved (approximately 10 minutes), making Solution B.

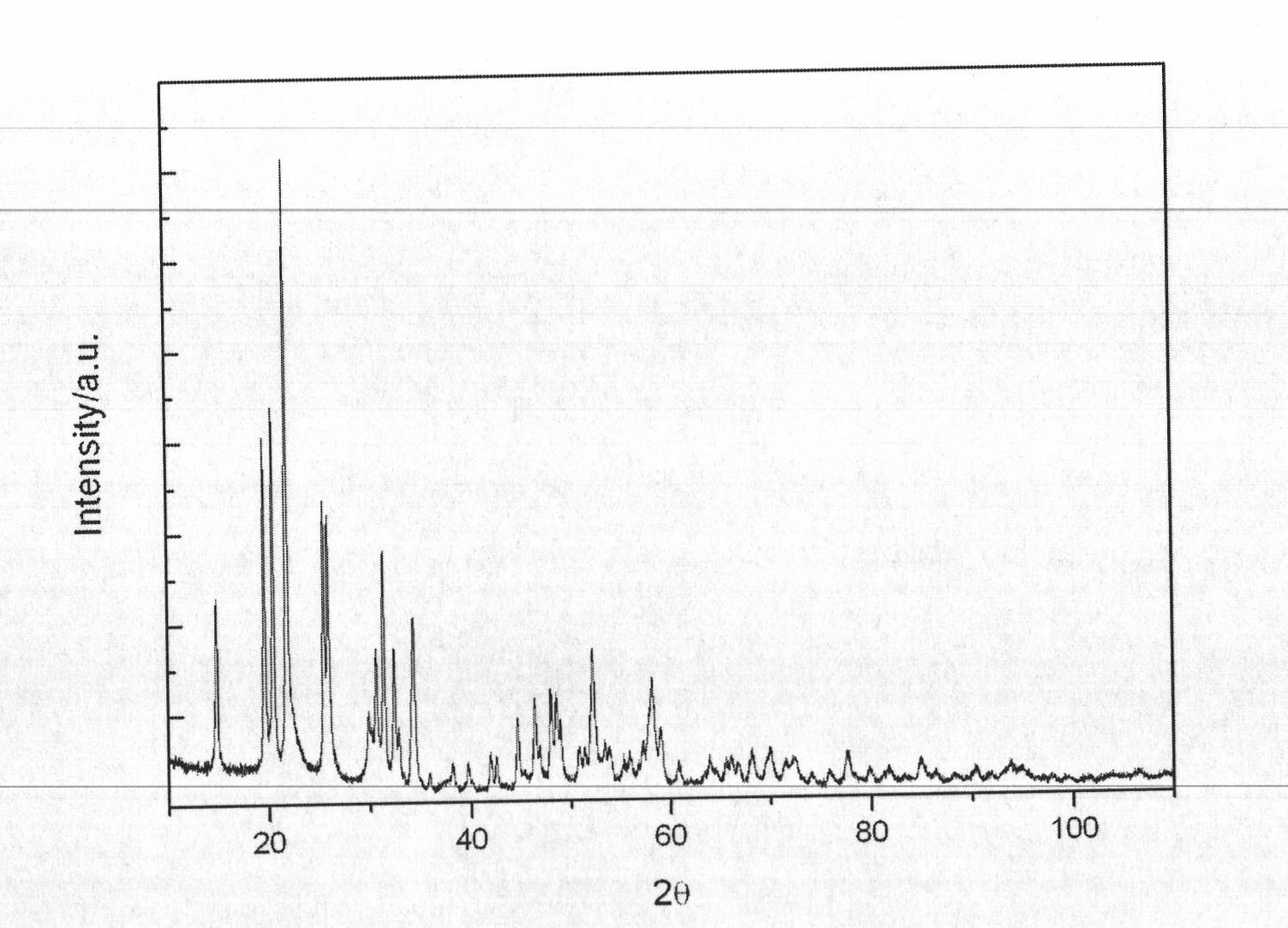

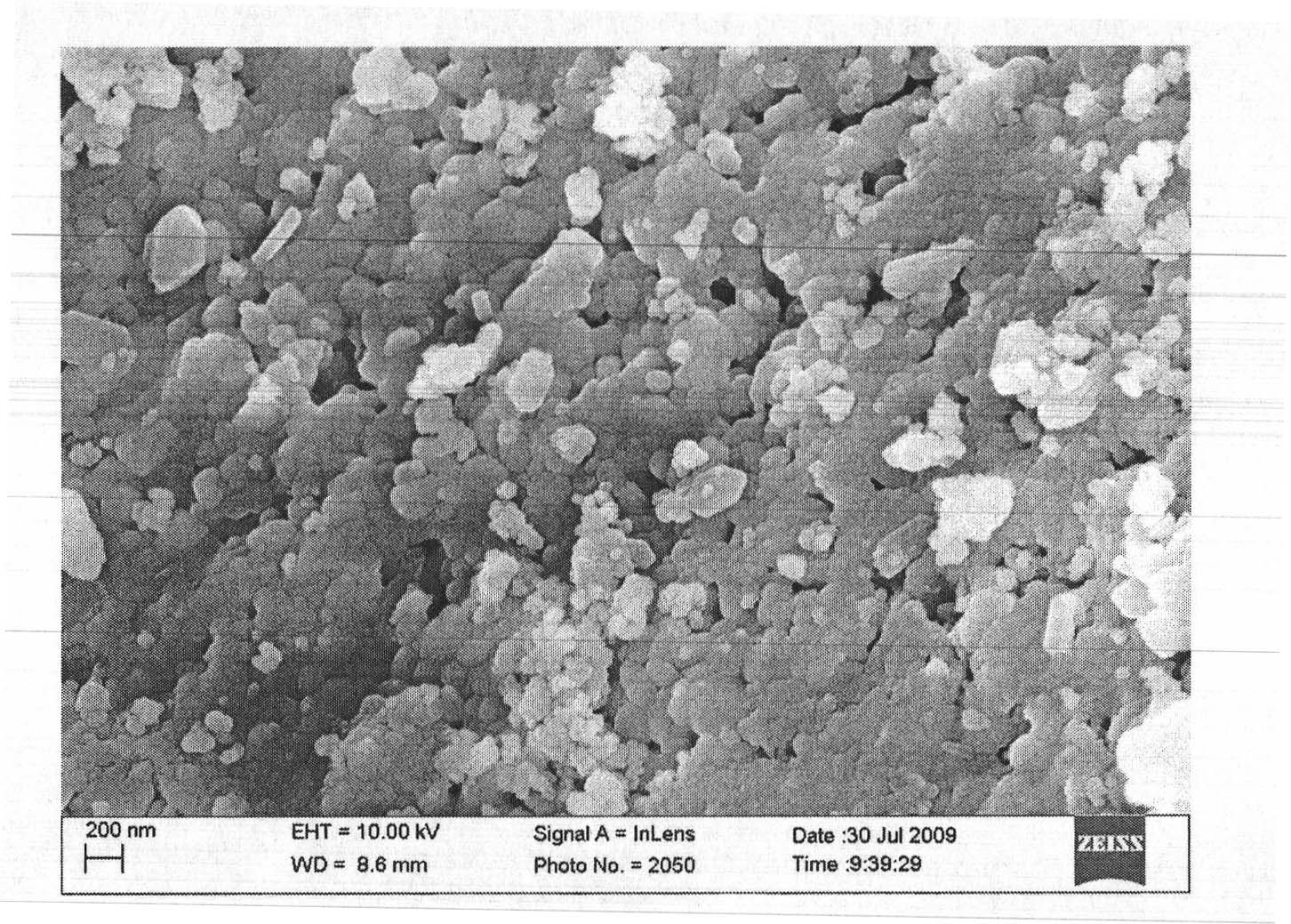

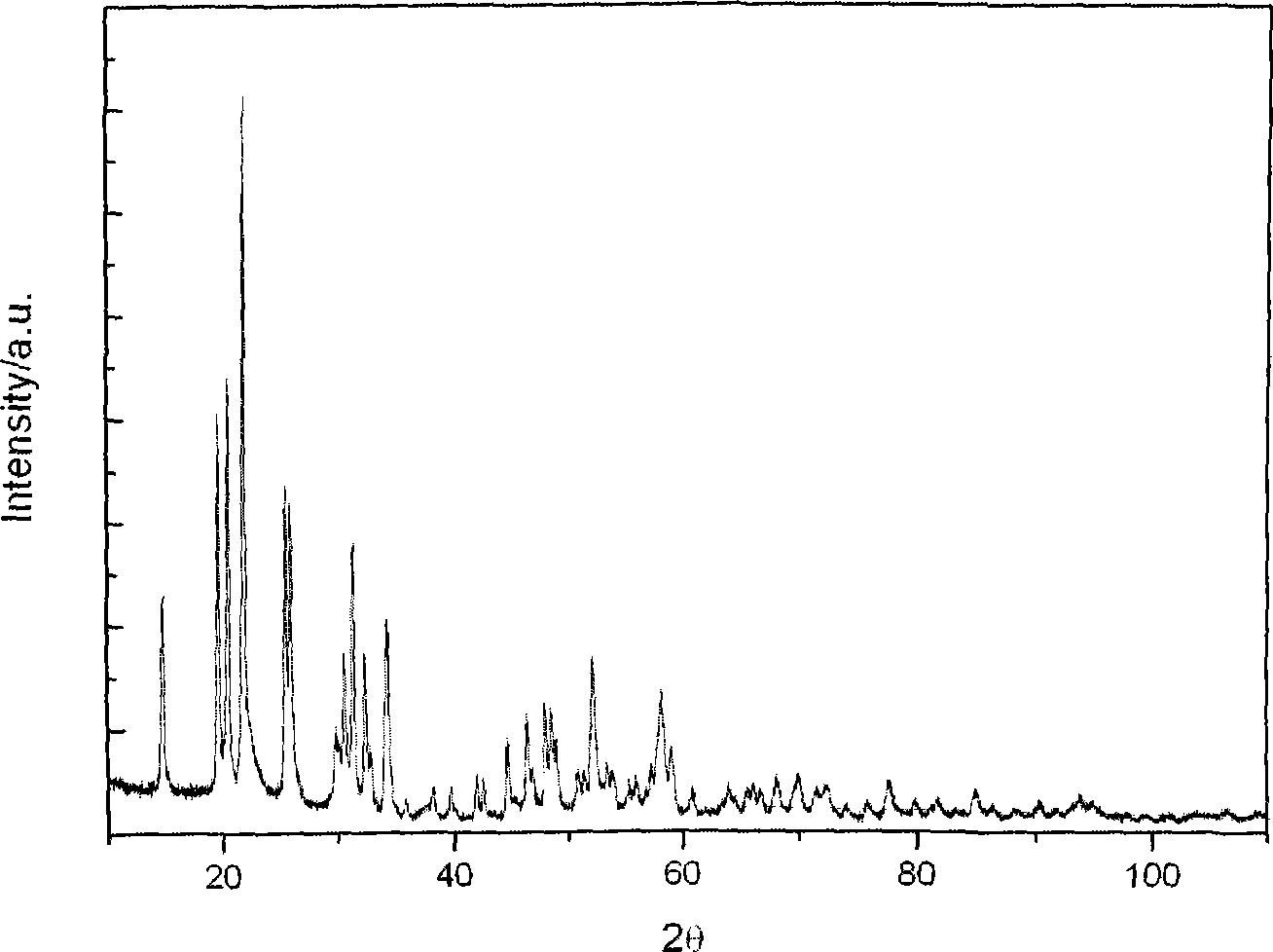

[0015] Preparation of NbVO 5 Powder: drop solution B into solution A, keep the temperature at 50-90°C, and keep stirring on a magnetic stirrer (about ...

Embodiment 2

[0018] Prepare solution A (Nb 2 o 5 solution): 1 g of Nb 2 o 5 Added to 50 ml of sulfuric acid, the temperature was maintained at 180 ° C, and kept stirring until Nb 2 o 5 All dissolved (about 2 hours). Inject the above solution into deionized water to precipitate Nb 2 o 5 ·nH 2 O was precipitated as flocculents and washed several times with deionized water, and the Nb 2 o 5 ·nH 2 The O precipitate was added to deionized water, and 3.794 g of C 2 h 2 o 4 2H 2 O, with constant stirring on a magnetic stirrer until Nb 2 o 5 ·nH 2 O is completely dissolved to make solution A.

[0019] Prepare Solution B: (NH 3 VO 4 solution): 0.8802 g of NH 3 VO 4 Add to 50 ml of deionized water, maintain the temperature at 50 °C, and keep stirring until Nb 2 o 5 All dissolved (approximately 10 minutes), making Solution B.

[0020] Preparation of NbVO 5 Powder: drop solution B into solution A, keep the temperature at 50-90°C, and keep stirring on a magnetic stirrer (about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com