Light heat-preserving brick and fabrication method thereof

A kind of insulation brick, lightweight technology, applied in the field of building materials, can solve the problems of unsightly appearance, unsightly appearance, unfavorable environmental protection, etc., and achieve the effect of reducing load bearing, light weight and improving grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

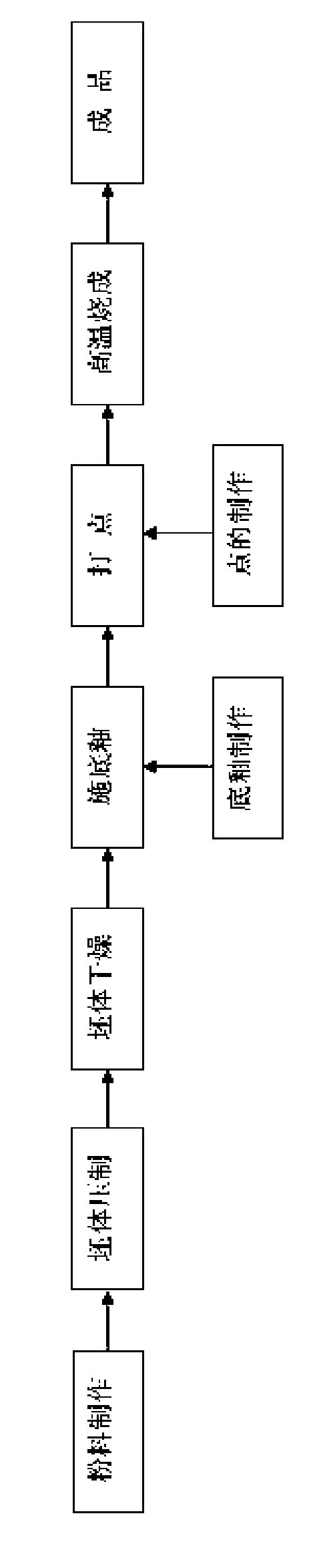

Method used

Image

Examples

Embodiment 1

[0041] Table 1 Body formula

[0042] raw material name

weight ratio

67

clay

5

white talc

22.5

4.5

1

0.5

[0043] Table 2 glaze point formula (weight ratio):

[0044]

Undercoat

Red dot

40

40

40

40

Longyan kaolin

12

12

12

12

Washed Ball Soil

5

5

5

5

[0045]

Undercoat

Red dot

8

8

8

8

10

10

10

10

barium carbonate

4

4

4

4

strontium carbonate

3

3

3

3

Aluminum oxide

5

5

5

5

10

/

/

/

Praseodymium yellow

0.3

1

1

2

gol...

Embodiment 2

[0056] Except that the formula is different from Example 1, the process of this example is basically the same as Example 1.

[0057] Weigh the corresponding raw materials according to the ratio of the green body formula in Table 3, and add them to the ball mill for grinding. The grinding time is 26 hours. At high temperature, the slurry turns into powder. Afterwards, the green body is made to the same as that of Example 1 until the dotting process. The sintering temperature of this embodiment is 1200°C high-temperature rapid sintering for 75 minutes.

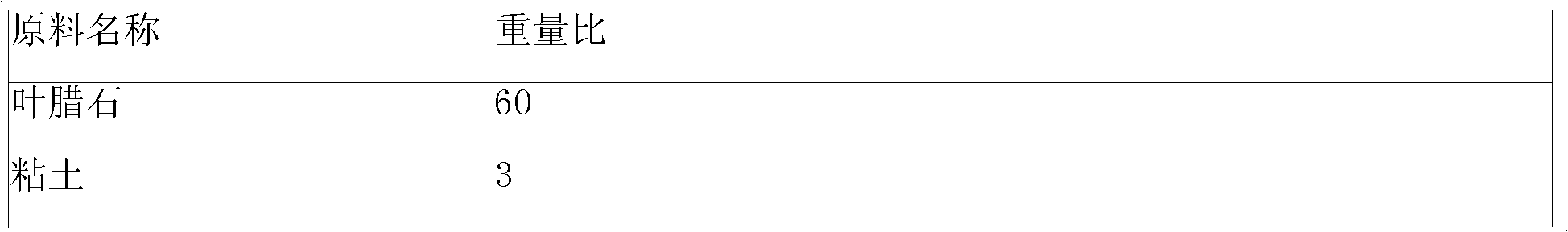

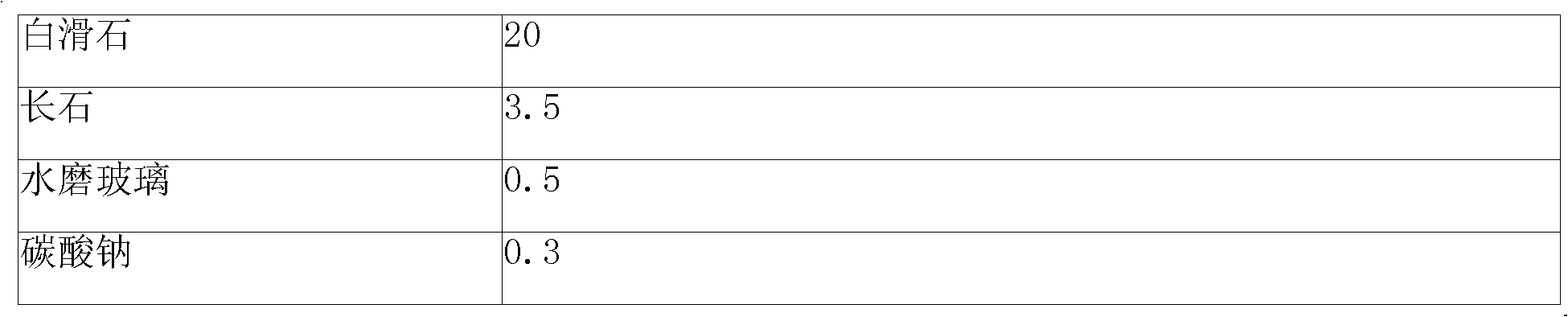

[0058] Table 3 Body Formula

[0059]

[0060]

[0061] Table 4 glaze point formula (weight ratio):

[0062]

[0063]

Embodiment 3

[0065] Except that formula is different from Example 1, the process of this example is the same as Example 1.

[0066] Weigh the corresponding raw materials according to the proportion of the body formula in Table 5, add them to the ball mill for grinding, and the grinding time is 20 hours. After the ball milling, unload the mud, pass the mud through a 200-mesh filter, and then inject the mud into the spray tower through the pipeline. At high temperature, the slurry turns into powder. Afterwards, the green body is made to the same as that of Example 1 until the dotting process. The sintering temperature of this embodiment is 1300°C high-temperature rapid sintering for 60 minutes.

[0067] Table 5 Body Formula

[0068] raw material name

[0069] Table six glaze point formula (weight ratio):

[0070]

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com