Silicon-based microcrystal heat-insulating material

A thermal insulation material and microcrystalline technology, applied in the field of thermal insulation materials, can solve the problems of poor construction performance, reduced product thermal insulation performance, poor fire performance, etc., and achieve the effects of stable thermal conductivity, good construction performance, and good temperature resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

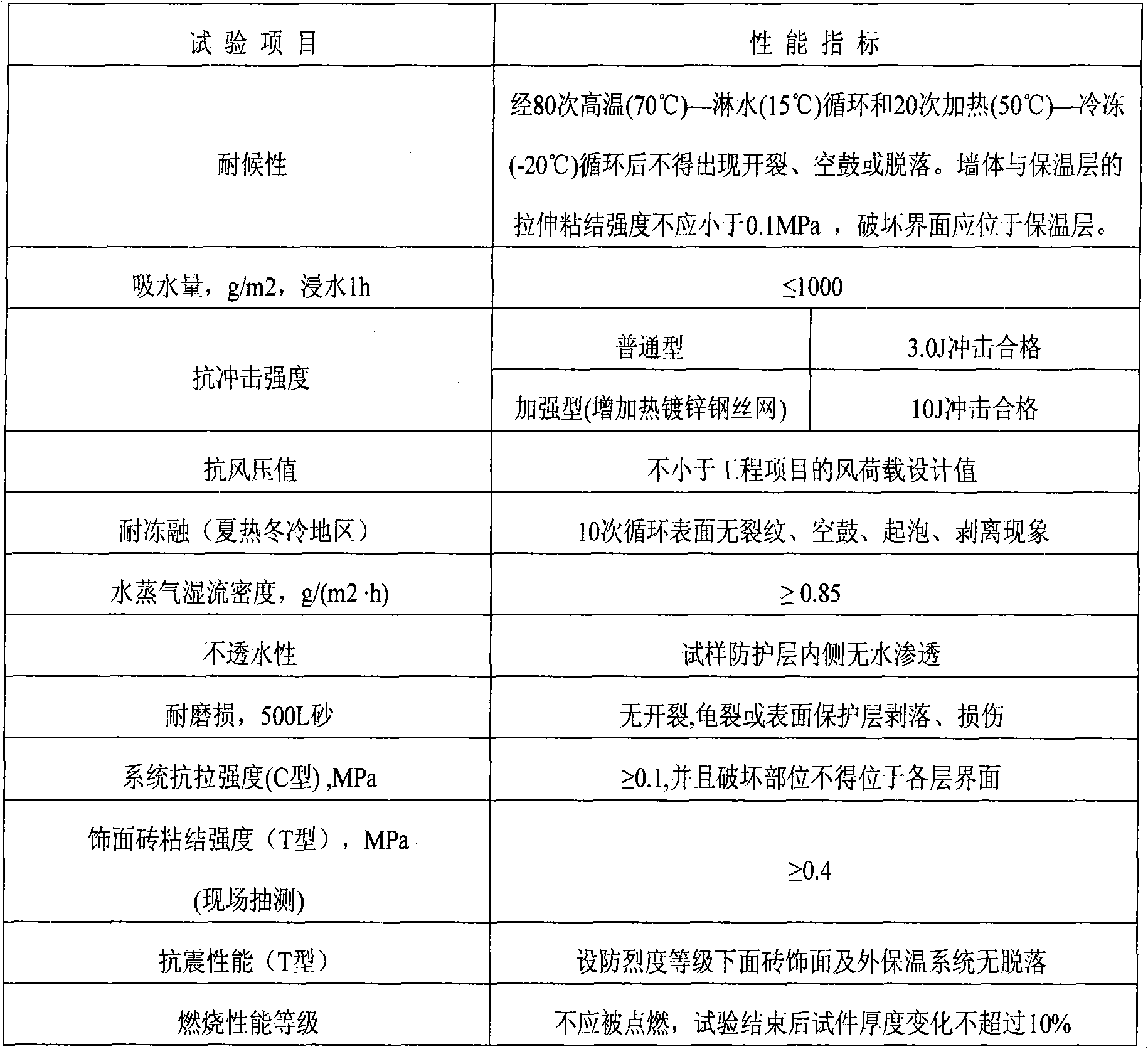

[0011] The structure of the thermal insulation system of the general wall is: base wall (concrete and various masonry walls), interface layer (interface agent), thermal insulation layer (that is, the silicon-based microcrystalline thermal insulation material of the present invention, referred to herein as silicon-based Microcrystalline thermal insulation mortar), anti-crack waterproof layer (crack-resistant waterproof mortar + acid-resistant mesh cloth or anti-crack waterproof mortar pressed into hot-dip galvanized welded mesh ), finishing layer (flexible water-resistant putty + paint Or face brick adhesive + face brick ).

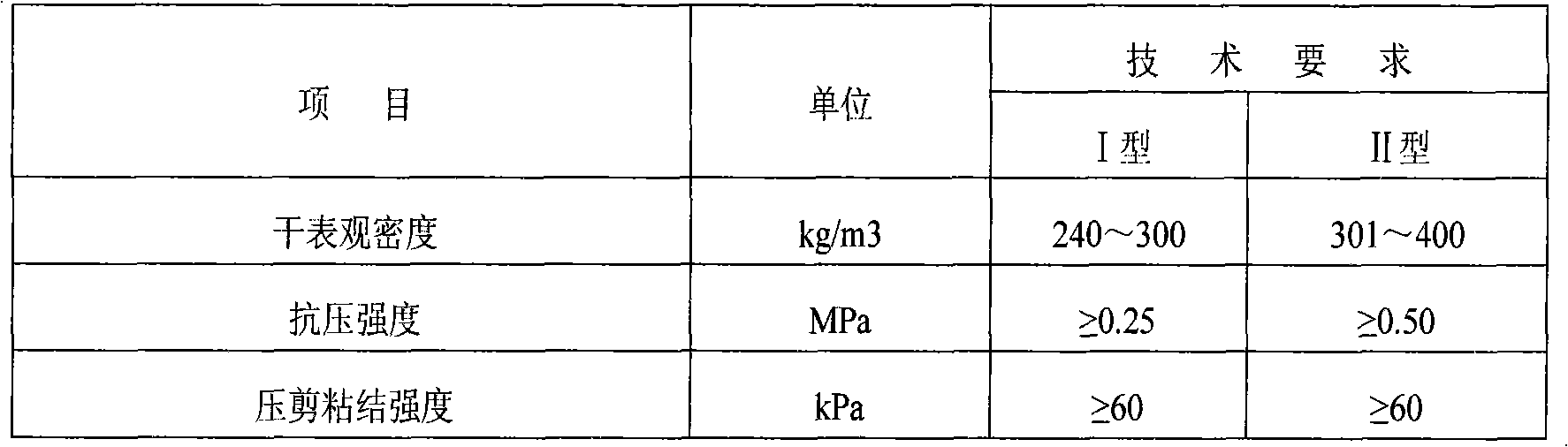

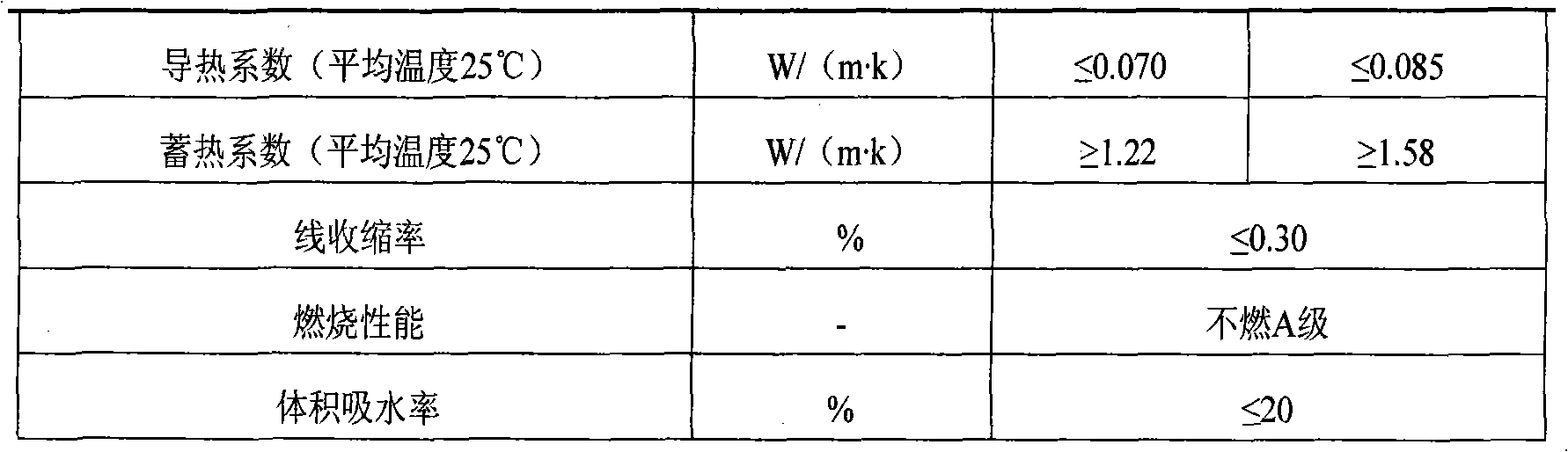

[0012] The thermal insulation layer adopts the silicon-based microcrystalline thermal insulation material of the present invention. The components of the material are silicon-based microcrystalline, inorganic gelling materials, anti-crack additives and auxiliary adhesives. The weight percentage of each component in the total material is It is: 30.5-46.5% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com