Latex mixing or solution mixing preparation method of rubber powder-rubber compound composition

A technology of composition and rubber emulsion, which is applied in the field of emulsion mixing or mixing preparation of rubber powder-rubber composite composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

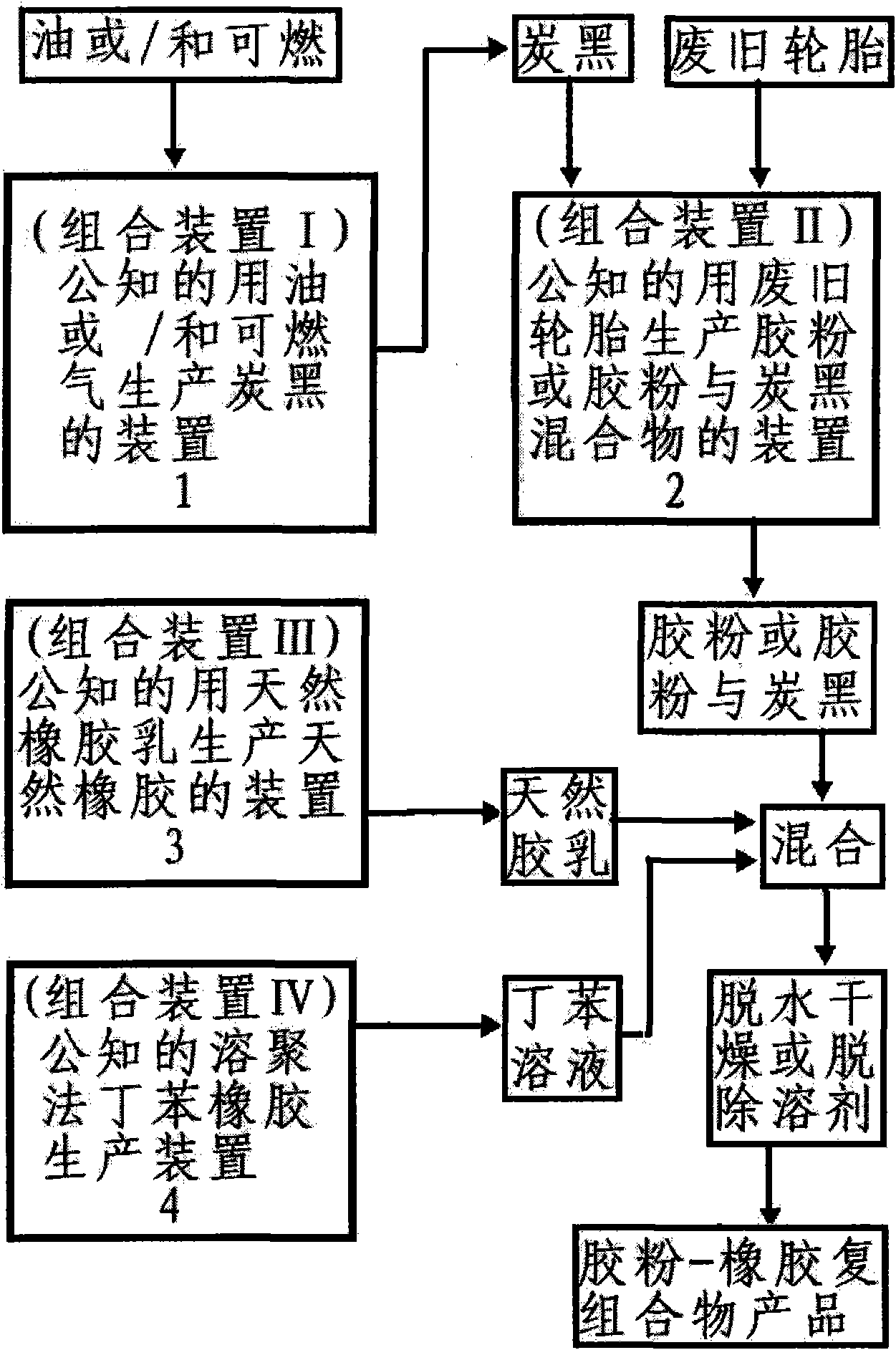

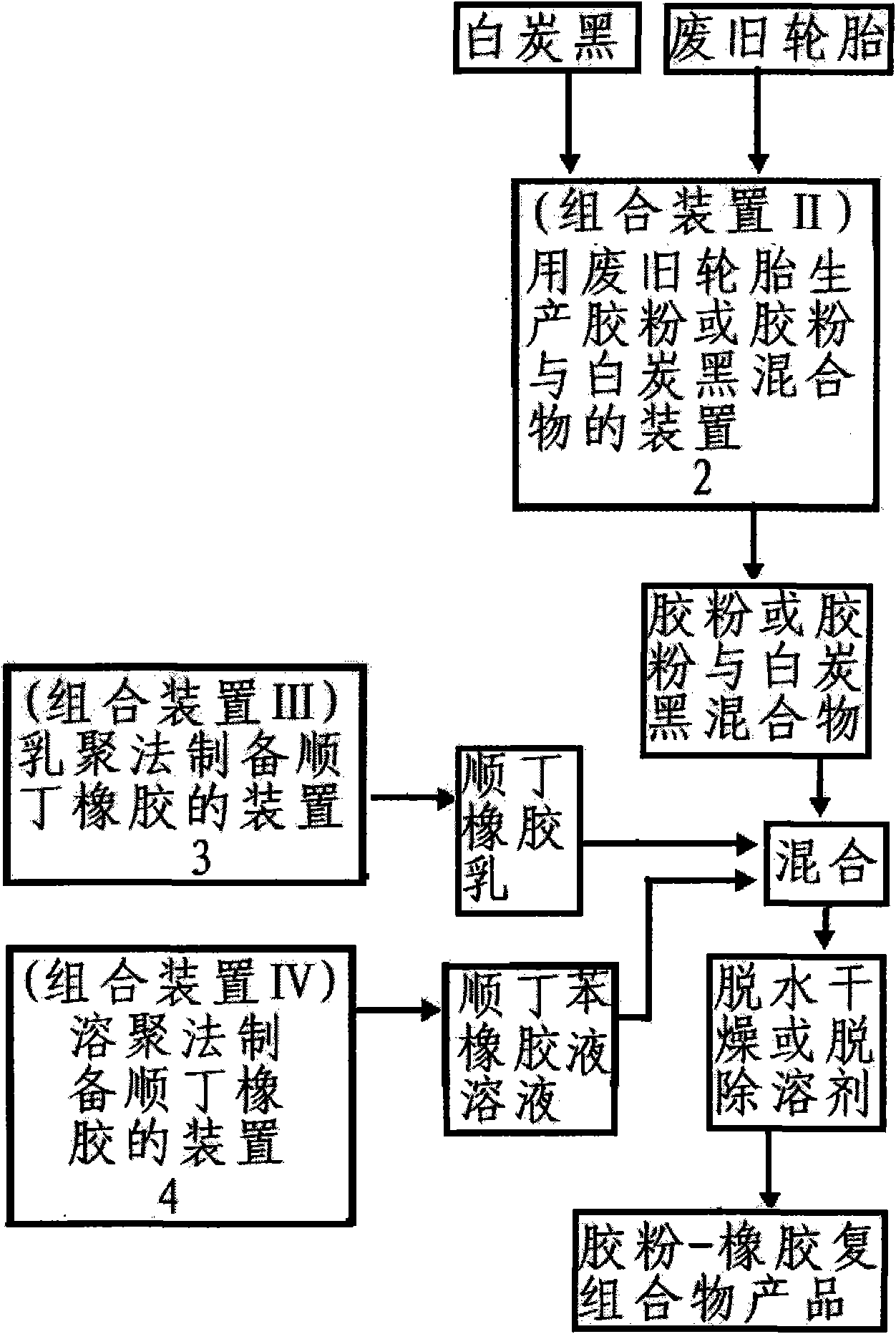

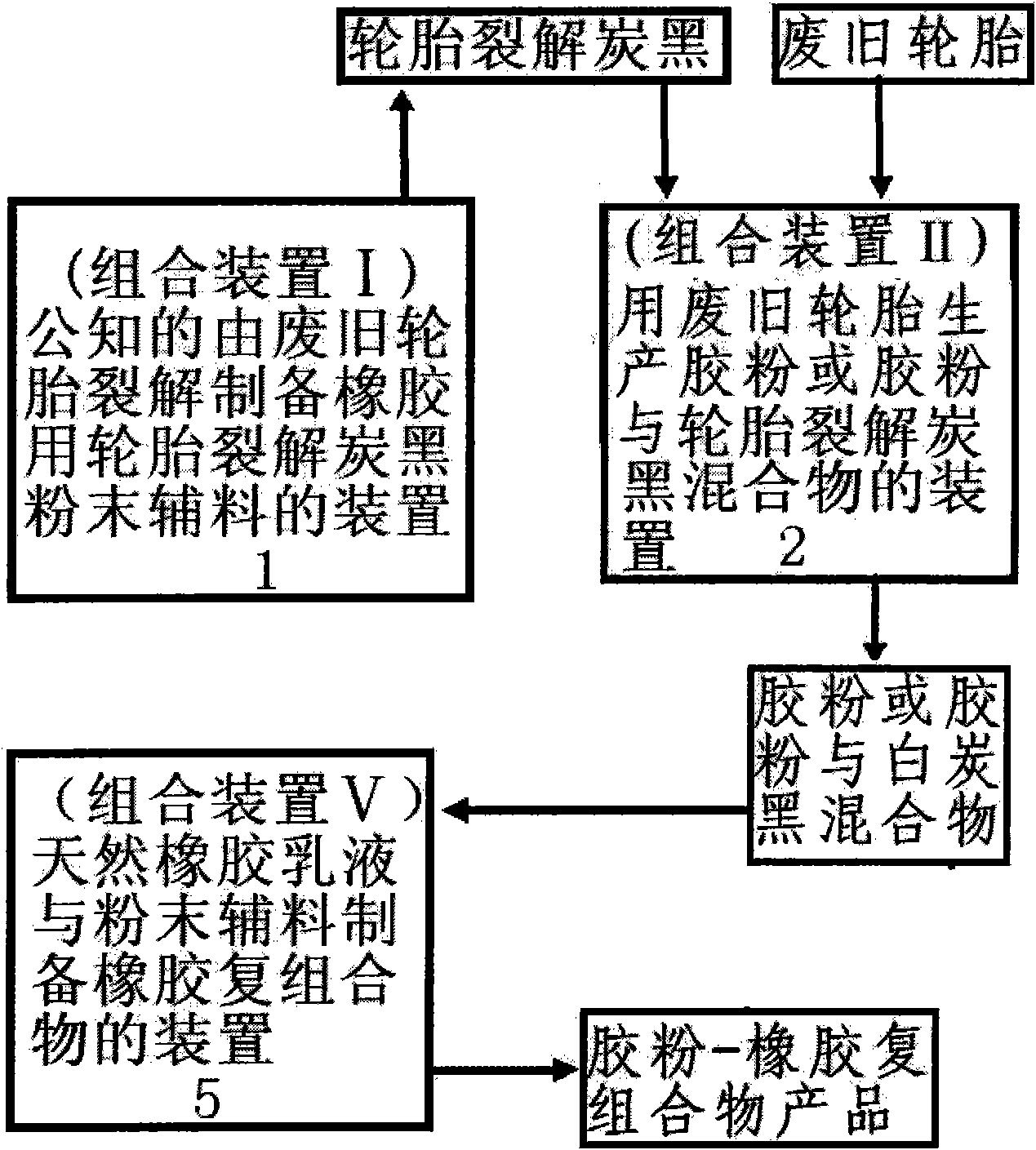

Method used

Image

Examples

Embodiment 1

[0118]Prepare 233 parts by weight of composite composition A masterbatch, wherein: the weight ratio of rubber powder and powder auxiliary materials to rubber is in the range of 133 / 100, and the weight ratio of rubber powder to powder auxiliary materials is in the range of 100 / 33. The specific steps are:

[0119] 1-1. Preparation of ultra-fine vulcanized rubber powder: 100 parts by weight of waste tire tread rubber particles of 20 to 30 mesh, thermal cracking carbon black 33 of waste tire side rubber and nylon miscellaneous fibers in waste tires finer than or equal to 200 mesh Parts by weight, add 0.033 parts by weight of nonionic surfactant (optional polyoxyethylene fatty alcohol ether), add 1 part by weight of stearic acid, mix with a stirrer, and the formula is pulverized by known normal temperature grinding disc fine rubber Machine pulverization, after processing with a cyclone classifier and a 100-mesh vibrating sieve, obtain about 133 parts by weight of vulcanized rubber p...

Embodiment 2

[0124] Prepare 155 parts by weight of composite composition A masterbatch, wherein: the weight ratio of rubber powder and powder auxiliary materials to rubber is in the range of 55 / 100, and the weight ratio of rubber powder to powder auxiliary materials is in the range of 100 / 450. The specific steps are:

[0125] 2-1. Preparation of superfine vulcanized rubber powder: use 10 parts by weight of 15-30 mesh waste tire tread rubber particles, 45 parts by weight of carbon black, and add 0.01 part by weight of anionic surfactant (optional sodium stearate) , after mixing with a stirrer, the formula is pulverized by a well-known room temperature disc-type fine rubber pulverizer, and then no need to use a cyclone classifier or a 100-mesh vibrating screen to obtain 99% finer than or equal to 100 mesh and mixed with surface rubber at one time. About 55 parts by weight of activating agent vulcanized rubber powder and powdered carbon black mixture are ready for use.

[0126] 2-2. Mixing an...

Embodiment 3

[0130] Prepare 160 parts by weight of composite composition A masterbatch, wherein: the weight ratio of rubber powder and powder auxiliary materials to rubber is in the range of 60 / 100, and the weight ratio of rubber powder to powder auxiliary materials is in the range of 100 / 250. The specific steps are:

[0131] 3-1. Preparation of superfine vulcanized rubber powder: use 20 parts by weight of waste tire tread rubber particles of 15-30 mesh, 10 parts by weight of white carbon black and 40 parts by weight of carbon black, add anionic surfactant (optional hard sodium fatty acid) 0.01 parts by weight, after mixing with a stirrer, the formula material is pulverized by a known normal temperature disc type fine rubber pulverizer, and then no need for classification and sieving process, just can get 89% finer than or equal to 100 mesh and mixed at one time There are about 60 parts by weight of the vulcanized rubber powder and powdered white carbon black and carbon black mixture of sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com