Temperature sensor based on zinc oxide nanowire

A zinc oxide nanowire and temperature sensor technology, which is applied to thermometers, thermometers and instruments using electrical/magnetic components directly sensitive to heat, etc. The effect of fast response and wide temperature measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

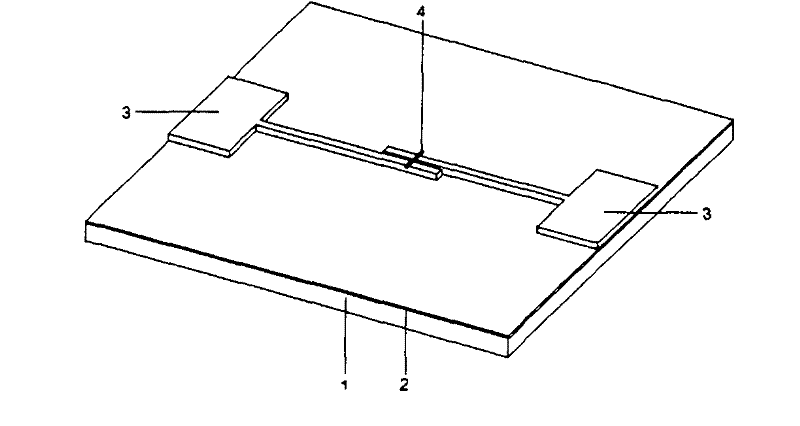

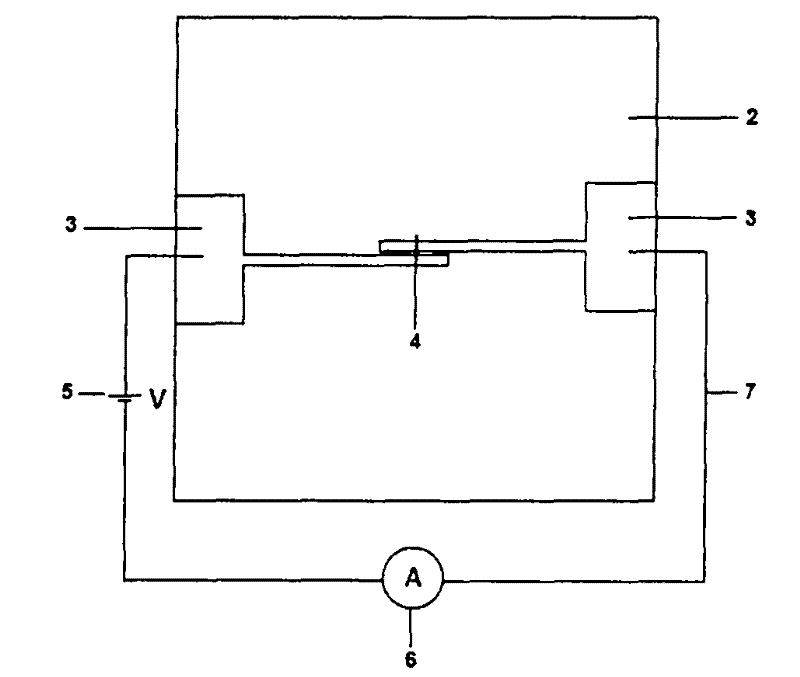

Embodiment 1

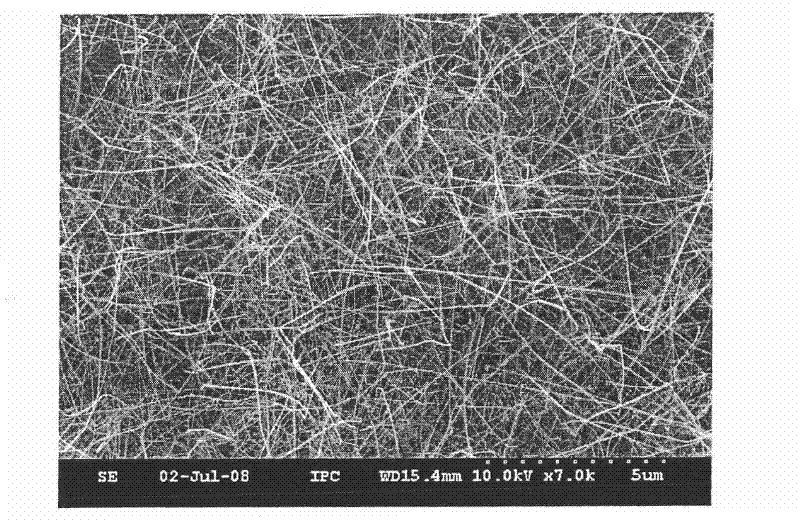

[0020] The silicon wafer substrate with microelectrodes was cleaned with acetone, ethanol and water in sequence, and dried with nitrogen gas. Zinc oxide nanowires with a diameter of 60-100nm and a length of 20-50μm were obtained by thermal evaporation, such as image 3 shown. After removing the zinc oxide nanowires from the silicon chip substrate, place them in absolute ethanol to form a uniform dispersion, get 0.1ml of the dispersion (wherein the zinc oxide nanowire content is less than 0.1mg) and drop it onto the silicon wafer with microelectrodes. On the chip, the external circuit is connected, and a pulse voltage of 0.1V and 50 Hz is applied to both ends of the zinc oxide nanowire to make the contact with the microelectrode more firm, that is, a temperature sensor based on the zinc oxide nanowire is formed. Exemplary measurements made in this example range from -180°C to 0°C. The relationship between its conductivity and temperature is shown in Figure 4. Figure a shows t...

Embodiment 2

[0022] The silicon wafer substrate with microelectrodes was cleaned with acetone, ethanol and water in sequence, and dried with nitrogen gas. Using an aqueous solution of zinc acetate at a concentration of 0.1mM and potassium chloride at a concentration of 0.1M as a growth solution, use an electrochemical method to obtain zinc oxide nanowires with a diameter of 100-300nm and a length of 3-5μm, such as Figure 5 shown. After removing the zinc oxide nanowires from the silicon chip substrate, place them in absolute ethanol to form a uniform dispersion, take 0.1ml of the dispersion (wherein the content of the zinc oxide nanowires is less than 0.1mg) and drop the dispersion onto the silicon substrate with the microelectrodes. On the chip, the external circuit is connected, and a pulse voltage of 1V and 500 Hz is applied to both ends of the nanowire to make the contact with the microelectrode more firmly, that is, a temperature sensor based on zinc oxide nanowire is formed. Exempla...

Embodiment 3

[0024] The silicon wafer substrate with microelectrodes was cleaned with acetone, ethanol and water in sequence, and dried with nitrogen gas. Using an aqueous solution of zinc acetate at a concentration of 0.5mM and potassium chloride at a concentration of 0.1M as a growth solution, use an electrochemical method to obtain zinc oxide nanowires with a diameter of 200-500nm and a length of 4-8μm, such as Figure 7 shown. Remove the nanowires from the silicon wafer substrate and place them in absolute ethanol to form a uniform dispersion, take 0.1ml of the dispersion (wherein the zinc oxide nanowire content is less than 0.1mg) and drop the dispersion onto the silicon wafer with the microelectrode , connect the external circuit, and apply a pulse voltage of 5V and 1000Hz to the two ends of the nanowire to make it more firmly in contact with the microelectrode, that is, to form a temperature sensor based on zinc oxide nanowires. The temperature range of the exemplary measurement ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com