Generation method for converting agricultural waste into solid fuel and prepared solid fuel

A solid fuel, waste technology, applied in the direction of waste fuel, solid fuel, biofuel, etc., can solve the problems of harm to the environment and organisms, high water content, high technical complexity, achieve strong capillary attraction, small volume per unit mass , the effect of increasing additional income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

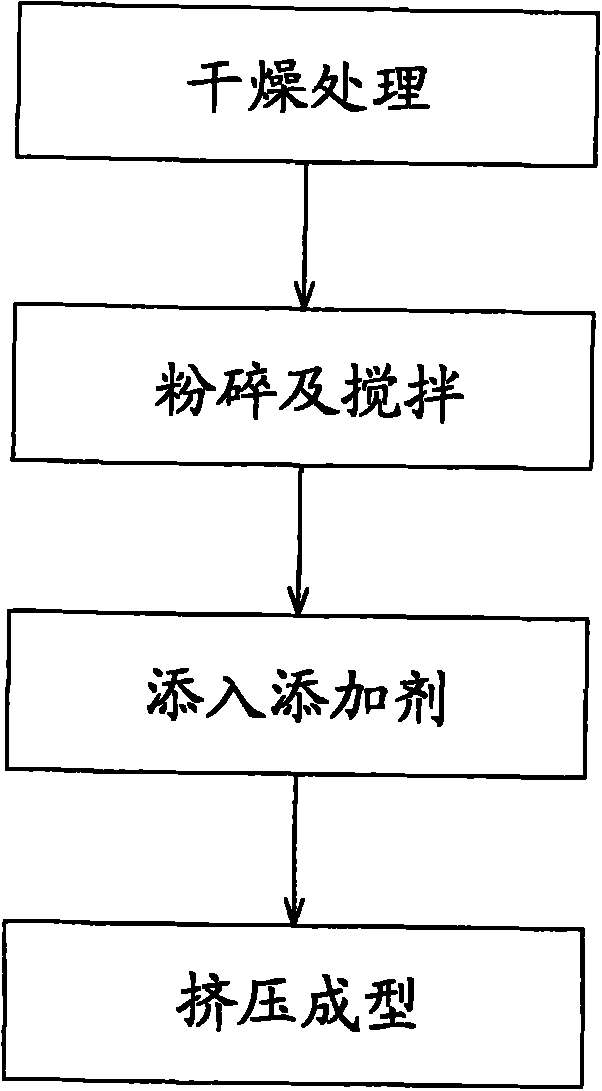

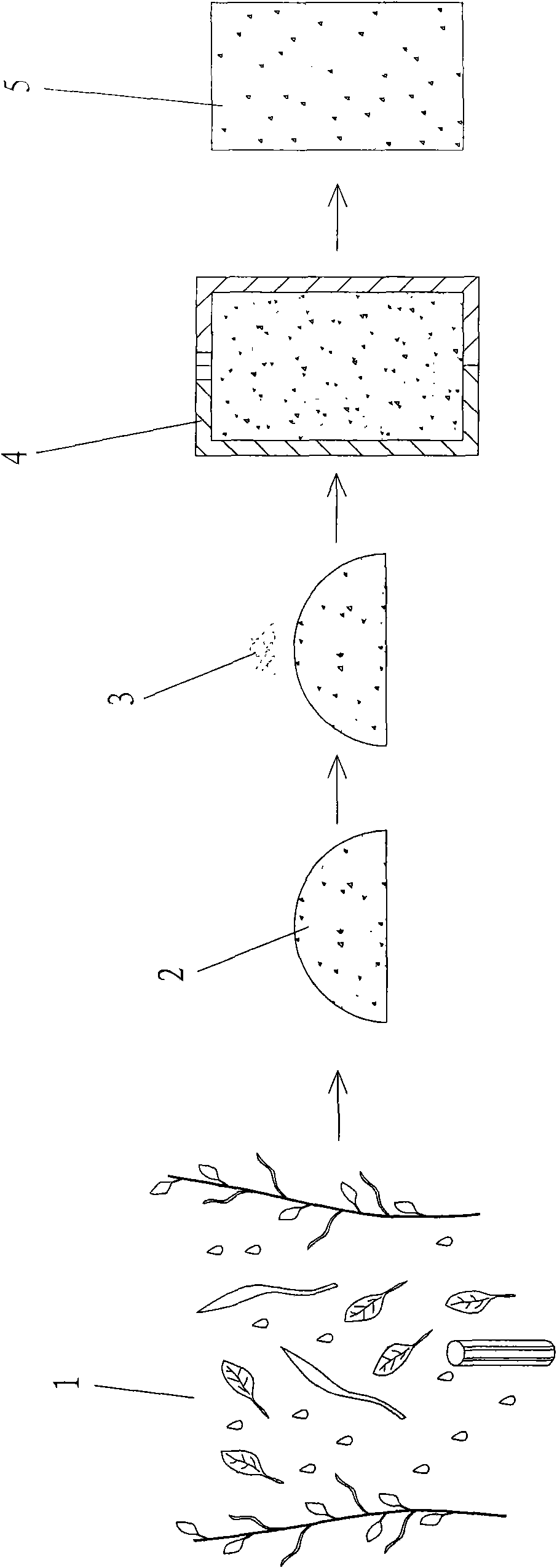

[0026] First, please refer to figure 1 and figure 2 As shown, the present invention is a method for converting agricultural waste into solid fuel and the solid fuel produced. The steps of the method are:

[0027] (1) Drying treatment: Dry the agricultural waste 1 to an average water content of 18% to 30%, wherein the agricultural waste 1 is rice husk, rice branch, hay or roots, stems and leaves of any plant, and the drying method is daily Drying in the sun or mechanical drying, and in order to avoid too high water content, it is not easy to burn, or the water content is too high during combustion, resulting in too much water vapor, which accelerates the corrosion and oxidation of the mechanism, and the white mist produced by water vapor is easy to cause people to misunderstand it as pollution. However, in order to avoid insufficient water content, resulting in subsequent defects that are difficult to form or easily broken after forming, the agricultural waste 1 such as rice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com