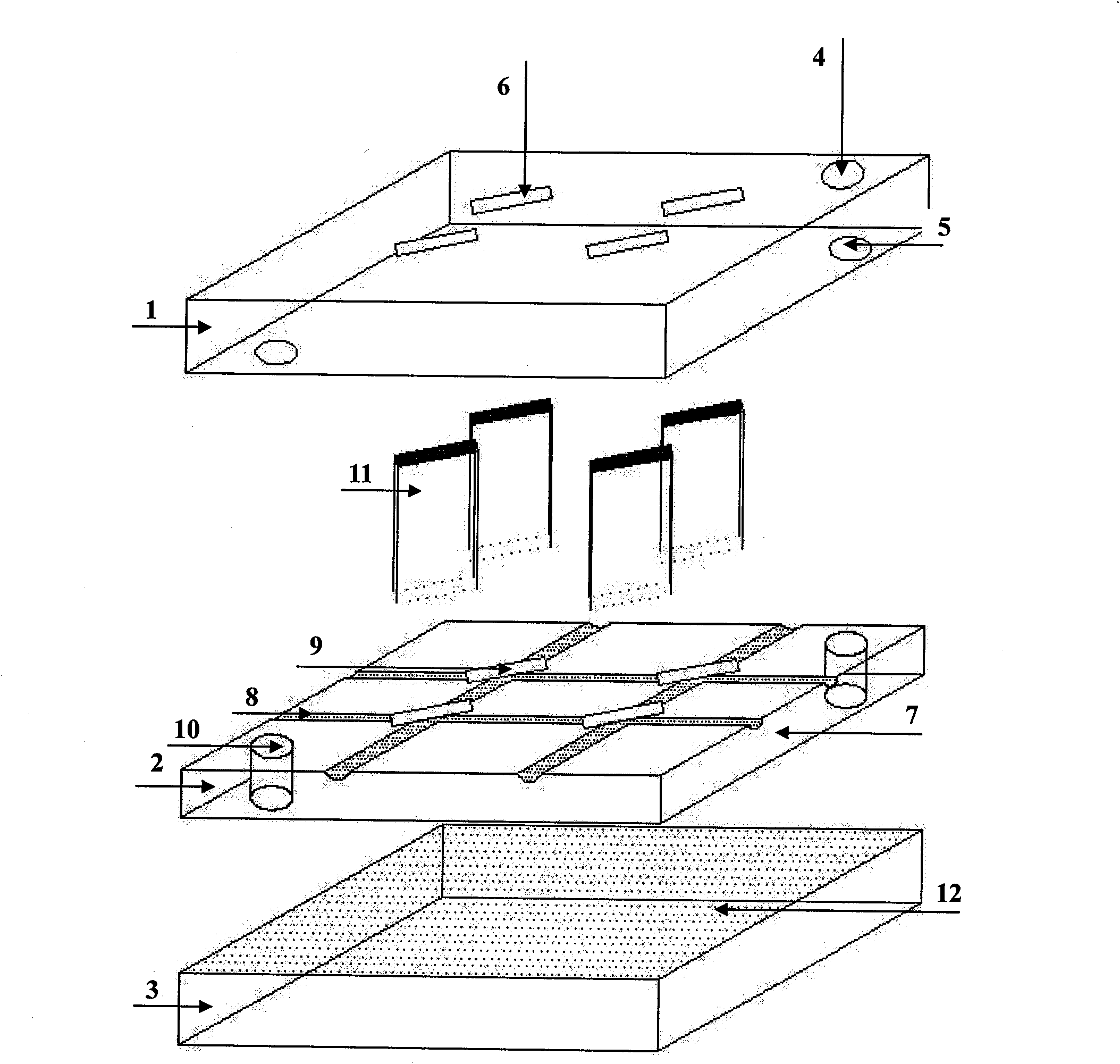

Two dimension electro-optical switch array device based on microfluidic technology

An electro-optical switch array and microfluidic technology, applied in the field of optical communication, can solve the problems of large power consumption, large size, slow corresponding speed, etc., and achieve the effects of easy fabrication, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] The waveguide layer is made of BK7 optical glass as the waveguide substrate. Because there are few internal impurities and defects, and the size of the internal defects is small compared with the light wavelength, the absorption loss and scattering loss are relatively low. The preparation method of the waveguide structure arranged in matrix form is through conventional coating, photolithography process and Ag + --Na + and K + --Na + ion exchange technology. At the node of the waveguide, a liquid chamber groove with the same size as the micro-container of the switch unit is made by ultrasonic method, and a gas-liquid connection hole is made at a convenient place on the substrate. The glass material with the same refractive index as the waveguide is selected to make the switch unit micro-container, and a transparent ITO conductive layer is sputtered on the inner side except the side facing the incident light. The insulating layer outside the conductive layer adopts th...

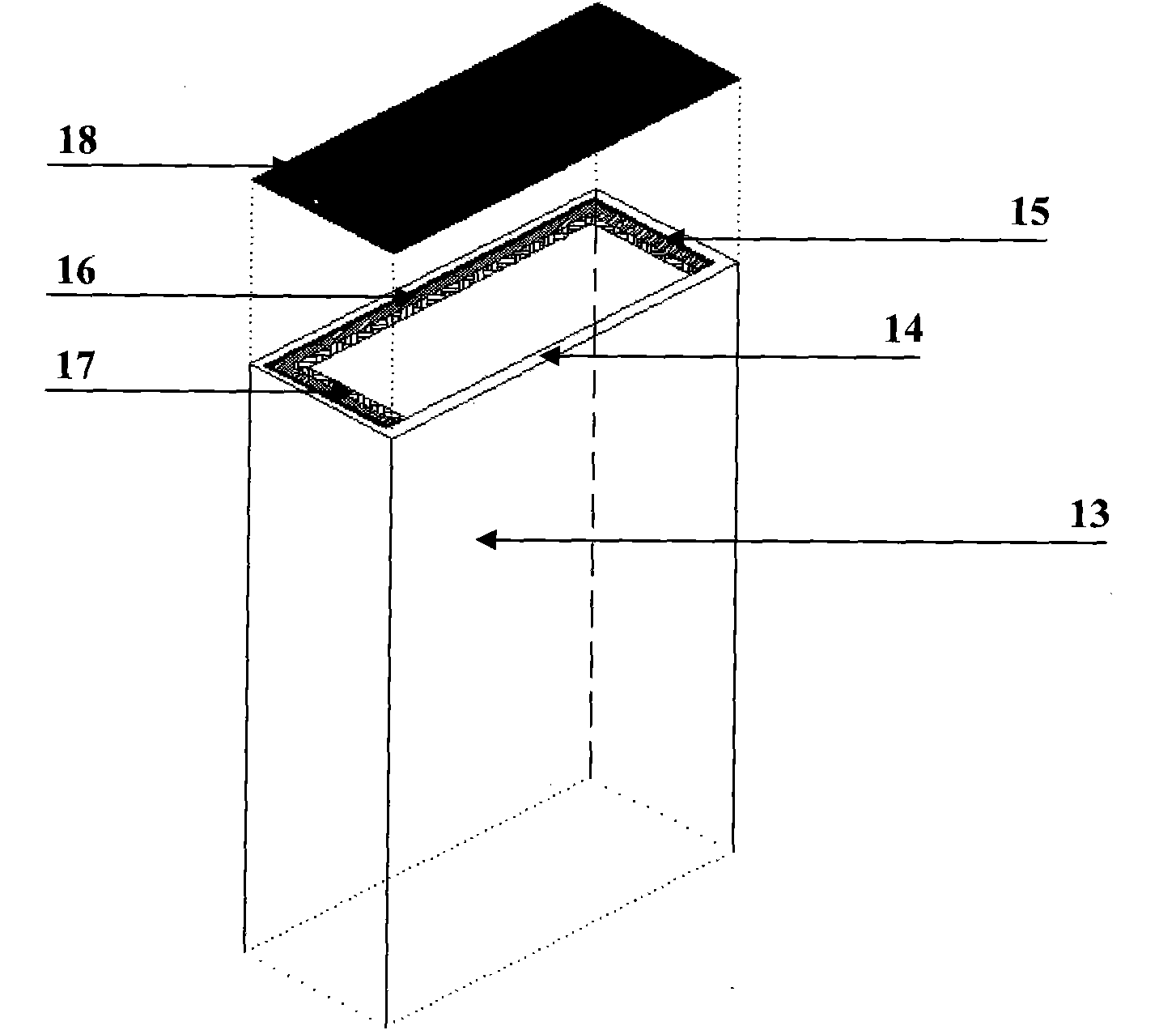

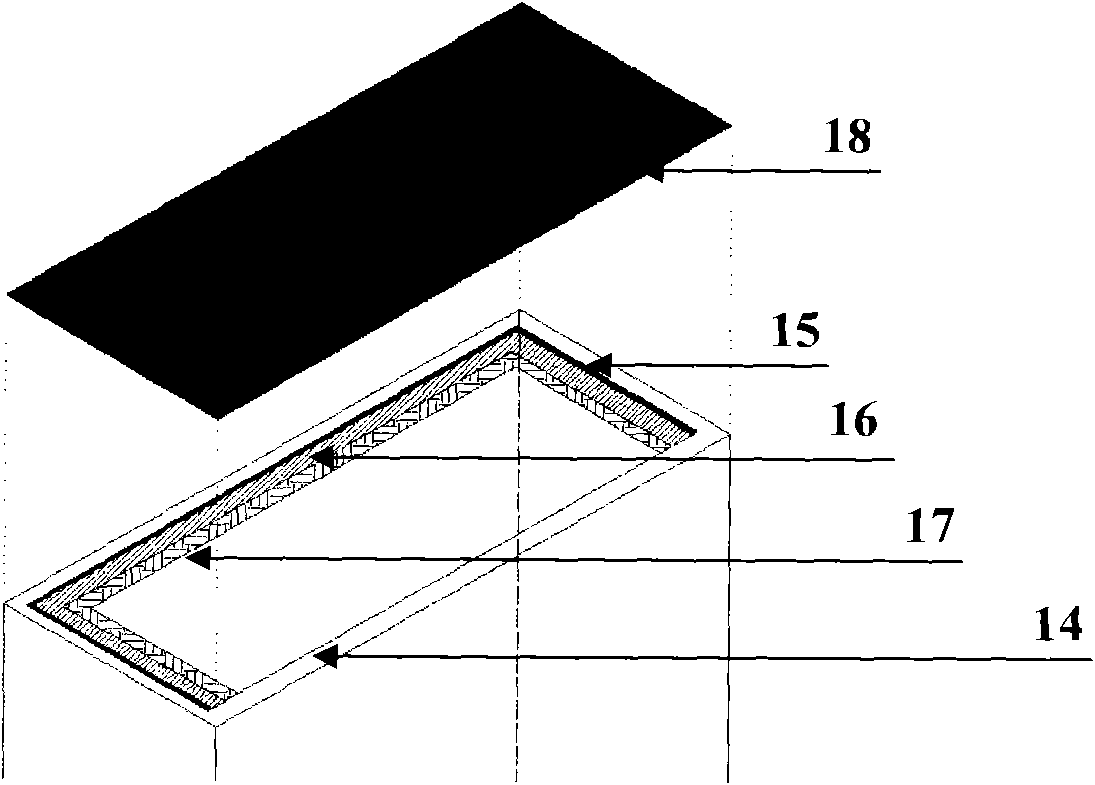

specific Embodiment 2

[0038] The waveguide layer uses monocrystalline silicon as the waveguide substrate, and micro-grooves are engraved on the waveguide position. A cylindrical lens is placed in each trench, and its central axis is on the same horizontal plane, and they are arranged in parallel or perpendicular to each other. The central axis extension lines of the four segments of cylindrical lenses around the optical switch unit intersect at a point on the surface of the optical switch unit. Silicone oil is used as the refractive index matching liquid of the device, which is also doped with some ether reagents until the refractive index is the same as that of the wall of the micro-container of the switch unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com