Hollow fibrous reverse osmosis composite membrane and preparation method thereof

A reverse osmosis composite membrane and hollow fiber technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of reducing the reliability of liquid processing, large structure of processing equipment, weak anti-pollution ability, etc., to achieve The water quality is good, the volume of retained material liquid is small, and the effect of strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

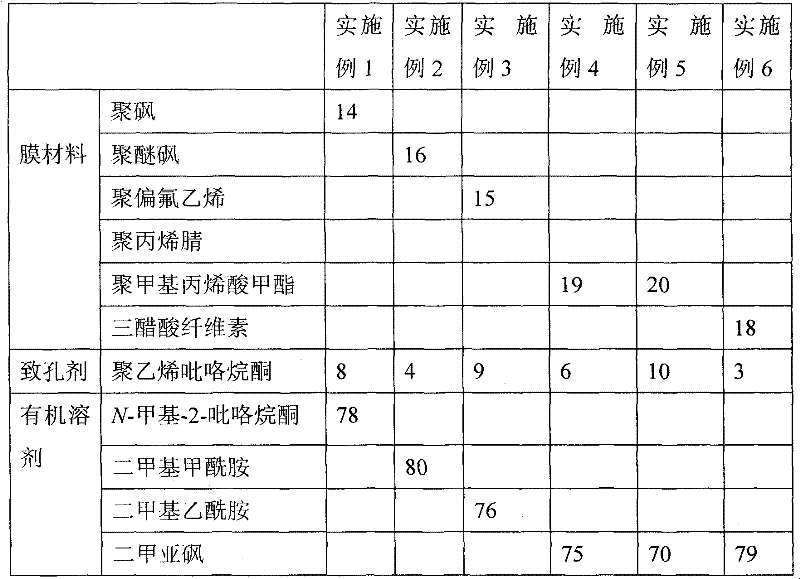

Examples

Embodiment Construction

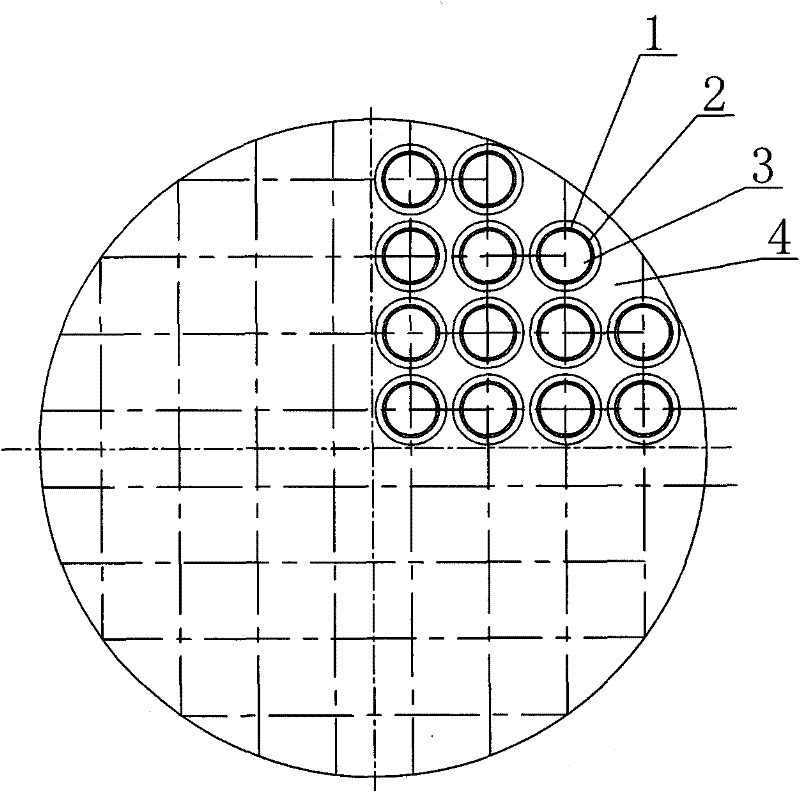

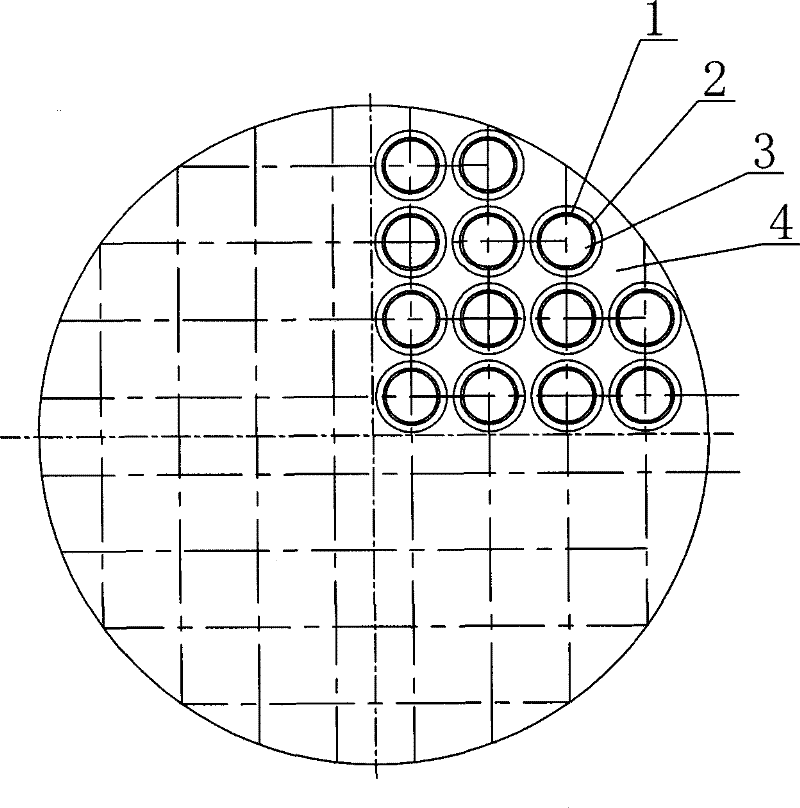

[0013] See figure 1 As shown, the hollow fiber reverse osmosis composite membrane of the present invention comprises more than ten hollow fiber membrane tubes 1 arranged side by side and sealedly connected to the outer walls of both ends. The outer walls of each fiber membrane tube 1 are sealed and fixed by colloid 4, and the fiber membranes There is an inner hole 2 in the tube 1, and 10-5000 fiber membrane tubes can be used to fix a plurality of fiber membrane tubes 1 into a bundle to form the hollow fiber reverse osmosis composite membrane of the present invention. The molecular weight cut-off of the fiber membrane tube is 15000-30000, In order to meet the requirements of ultrafiltration, the inner diameter of each fiber membrane tube is 0.8-1.0mm, and the wall thickness is 0.5-0.7mm. There is a polyamide active layer 3 generated by polymerization reaction on the inner hole wall of each fiber membrane tube. The thickness of the active layer 3 is 3-100nm, and the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com