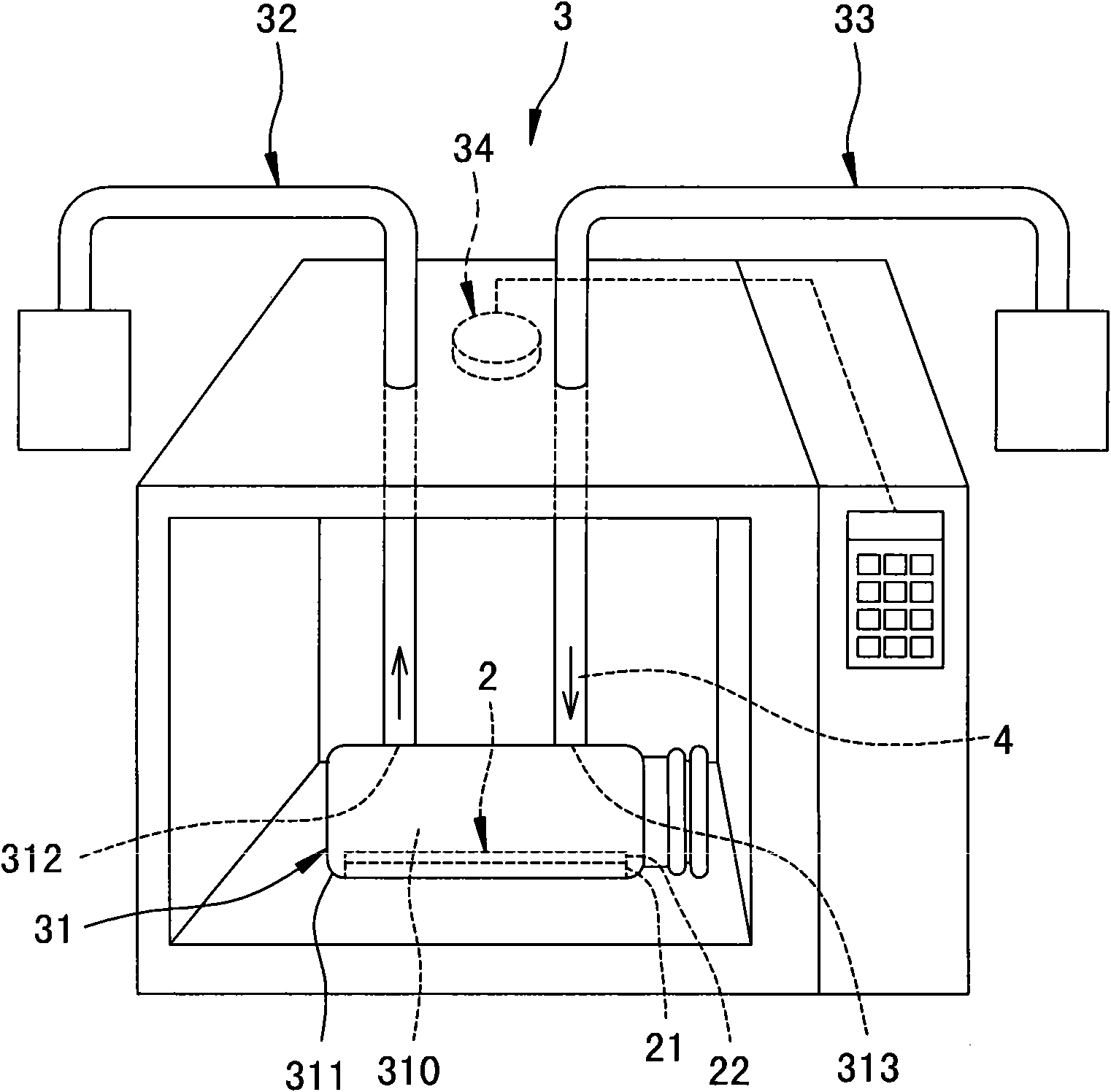

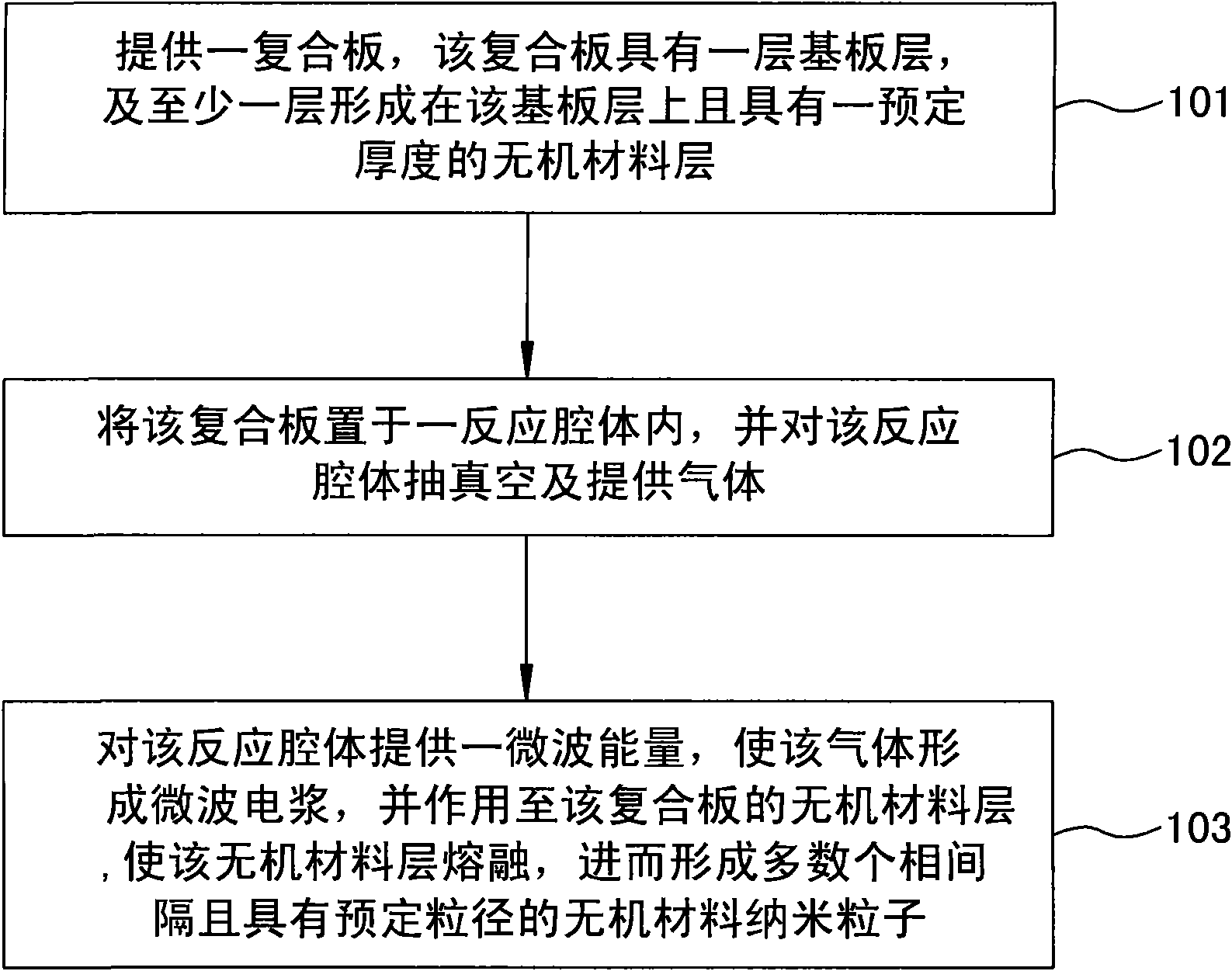

Method for preparing nanoparticles of inorganic material and device for applying same

A nanoparticle and inorganic material technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as poor efficiency, time-consuming, and inability to manufacture nanoparticles in a large area, achieving good manufacturing efficiency and reducing manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]

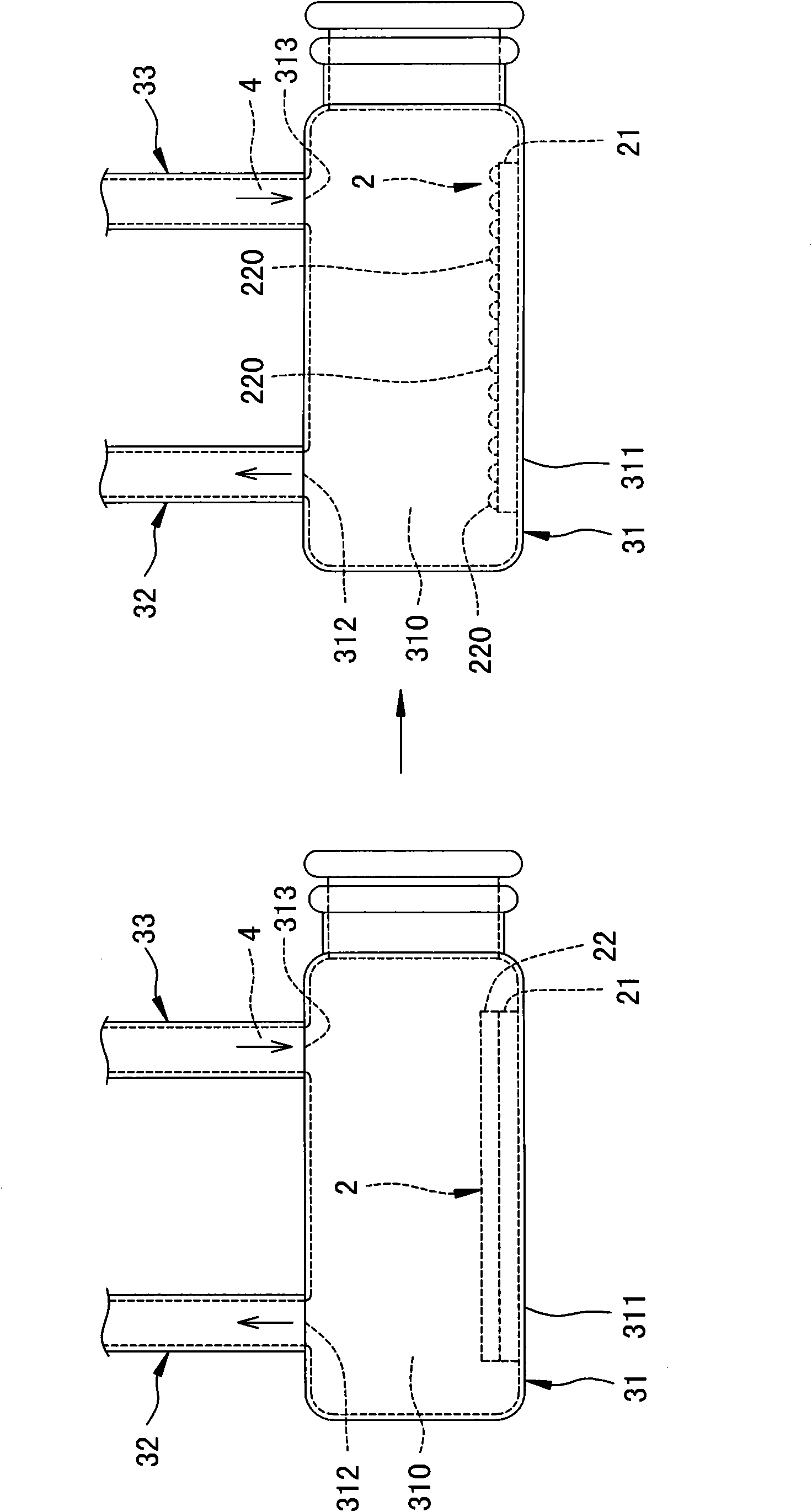

[0054] (1) Prepare 8 pieces of composite components: cut into 1 cm × 1 cm base material, 8 pieces in total, put the base material into acetone, ethanol, and deionized water respectively, and vibrate for 5 minutes under ultrasonic waves, with Remove some dust contamination from the surface of the substrate. Then use nitrogen to dry the surface of all substrates, and then soak the substrates in a piranha solution (piranha solution, H 2 SO 4 with H 2 o 2 Mixed according to the ratio of 3:1, and the temperature of 80 ℃ mixed liquid) for 30 minutes to remove some organic residues on the surface of the substrate, and then rinse with a large amount of deionized water, and then nitrogen gas Substrate blow dry completely.

[0055] Put the 8 pieces of substrates that have been cleaned through the aforementioned procedures into a sputtercoater, and use a film thickness controller to control the thickness of the inorganic material layer sputtered on the substrate to the req...

Embodiment 2

[0059]

[0060]With the preparation method of , prepare 5 clean substrate sheets, and form inorganic material layers with a thickness of 1nm, 2nm, 3nm, 4nm, and 5nm on the substrate sheets respectively, and the corresponding microwave The action time of the energy is 3 seconds, 6 seconds, 9 seconds, 12 seconds, and 15 seconds respectively. The device used and the setting parameters are the same as in , except that the material of the inorganic material layer is changed to silver , after microwave plasma treatment, the composite components with different thicknesses of inorganic material layers are processed by microwave plasma and the nanoparticles formed on the substrate are changed from thin to thick according to the thickness of the original inorganic material layer, respectively Marked as Specimen (II 1 ), (II 2 ), (II 3 ), (II 4 ), (II 5 ), the obtained result is as Image 6 and Figure 7 As shown, it shows that the particle size of the nanoparticles still increas...

Embodiment 3

[0061]

[0062] Similar to the method of , prepare 5 clean substrate sheets, and form inorganic material layers with a thickness of 1nm, 2nm, 3nm, 4nm, and 5nm on the substrate sheets, and the corresponding The action time of microwave energy is respectively 15 seconds, 18 seconds, 21 seconds, 24 seconds, and 27 seconds. The device used and the setting parameters are the same as , except that the material of the inorganic material layer is changed to copper, and The pressure of the chamber is controlled at 1.0 torr, and oxygen is fed into the chamber to prepare microwave plasma nanoparticles in an oxygen environment. After microwave plasma treatment, the composite components with different thicknesses of inorganic material layers The nanoparticles prepared after microwave plasma treatment and formed on the substrate are marked as samples (III) according to the thickness of the inorganic material layer from thin to thick. 1 ), (III 2 ), (III 3 ), (III 4 ), (III 5 ), the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com