Preparation method of porous PbS nano sheet

A technology of nanosheets and organic molecules, which is applied in the field of preparation of porous PbS nanosheets, can solve the problems of difficult shape control and numerous steps, and achieve excellent visible light photodegradation performance, simple steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

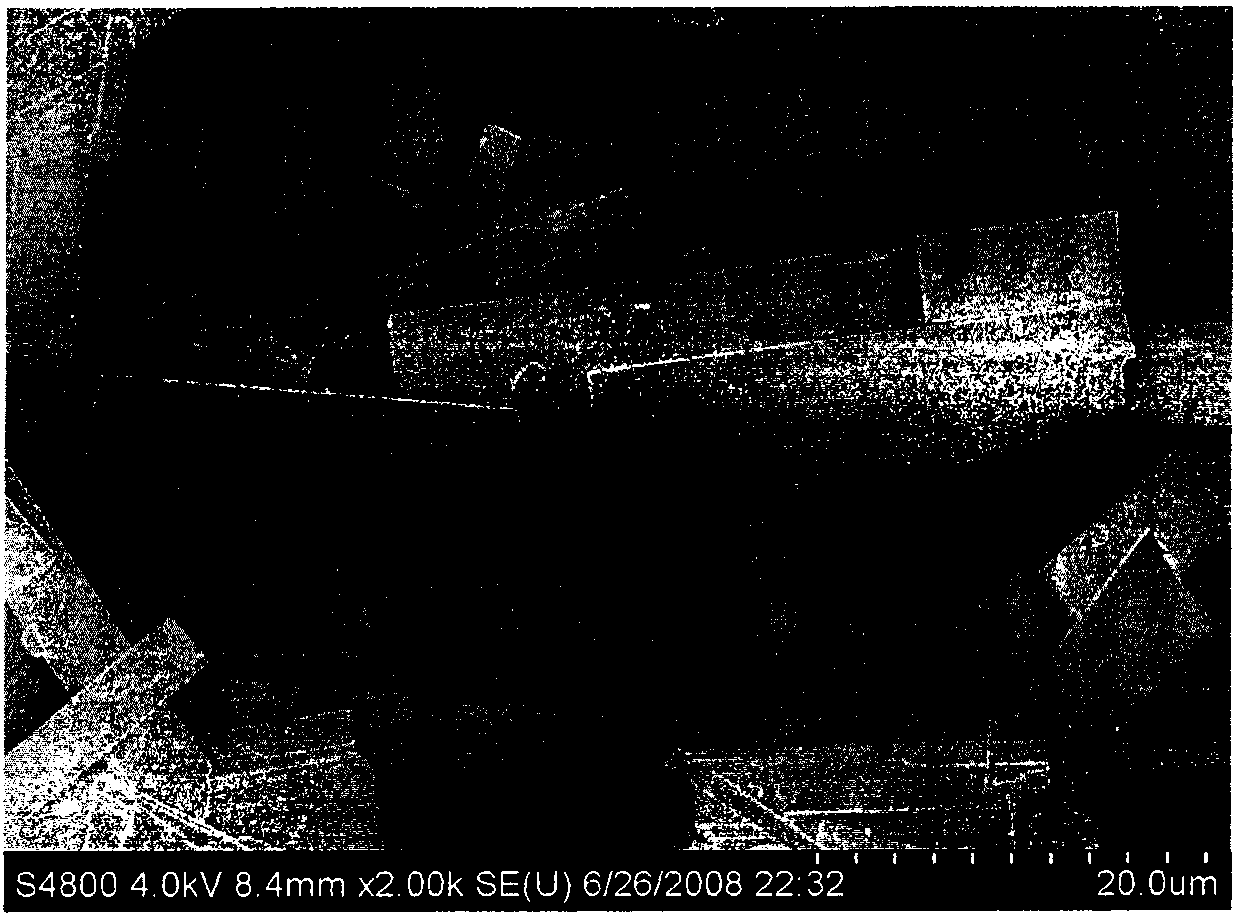

[0032] Embodiment 1: the preparation of porous PbS nano sheet material

[0033] Add d=1.220g / ml, 19.8-39.5μL of thioglycolic acid to 15mL of 0.01M lead perchlorate aqueous solution, and immediately produce white precipitate. Adjust the pH to 8-13 with aqueous sodium hydroxide solution and hydrochloric acid. Place the prepared reaction solution in a constant temperature box at 37°C and let it stand. After a large amount of white precipitate is formed, centrifuge and wash it with secondary water for 3 times at a speed of 8000-15000 rpm to obtain lead thioglycolate with a nanosheet structure. Looks like figure 1 shown.

[0034] Move the resulting lead thioglycolate to 0.001-1 M, 500 mL of Na 2 After reacting in S aqueous solution at 37° C. for 0.1-3 h, filter and separate, and dry in a vacuum oven to obtain black powdery PbS, the microscopic appearance of the black powdery PbS is porous nanosheet.

Embodiment 2

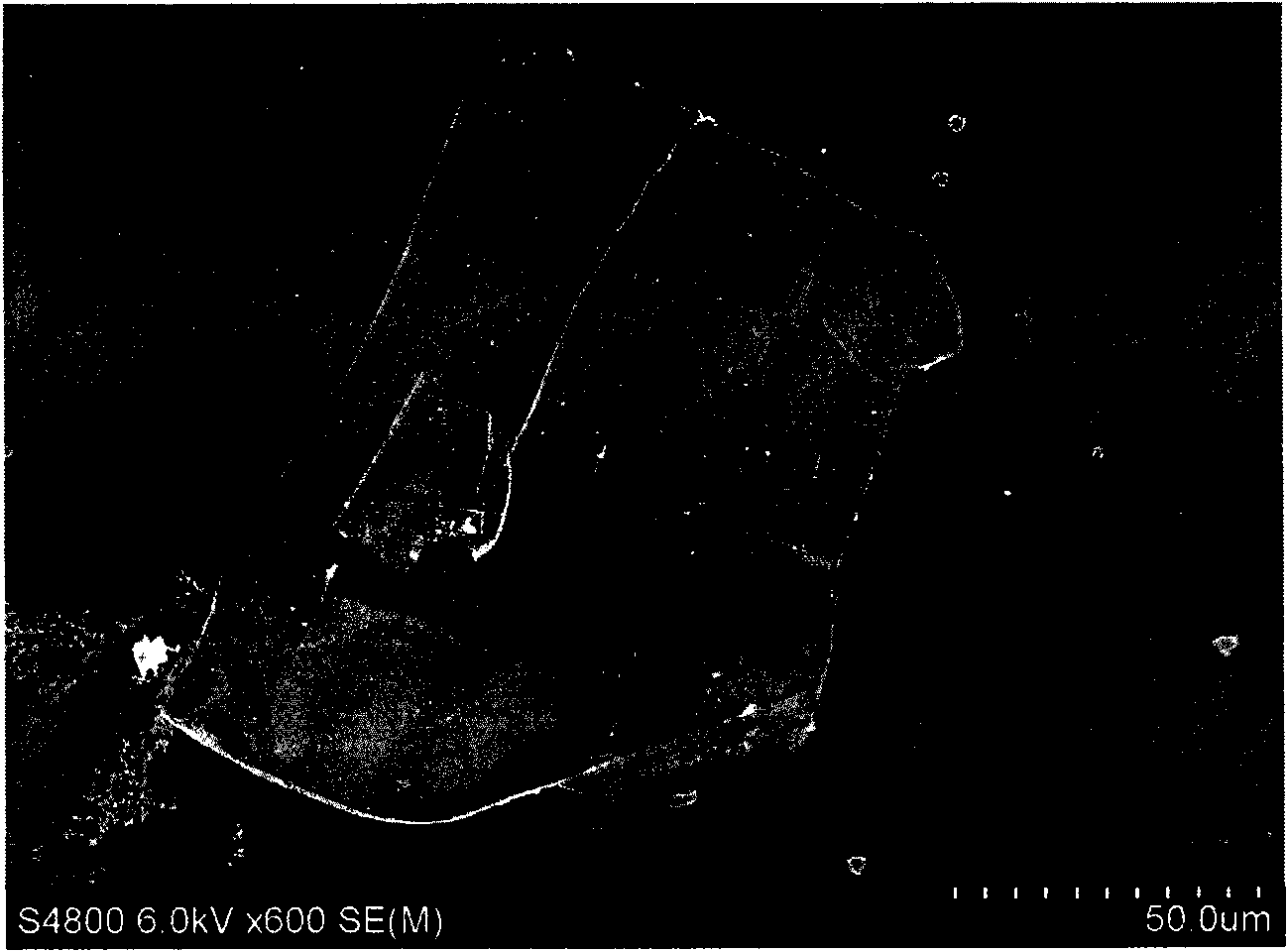

[0035] Embodiment 2: the preparation of porous PbS nano sheet material

[0036] Add 33.0-52.8μL of mercaptopropionic acid to 15mL of 0.01M lead perchlorate aqueous solution, and a white precipitate is produced immediately. Adjust the pH to 8-13 with aqueous sodium hydroxide solution and hydrochloric acid. Put the prepared reaction solution in a constant temperature box at 37°C and let it stand. After a large amount of white precipitate is formed, centrifuge and wash it with secondary water for 3 times at a speed of 8000-15000 rpm to obtain lead mercaptopropionate with a nanosheet structure. looks like figure 2 shown.

[0037] Move the resulting lead mercaptopropionate to 0.001-1 M with 500 mL of Na 2 After reacting in S aqueous solution at 37° C. for 0.1-3 h, filter and separate, and dry in a vacuum oven to obtain black powdery PbS, the microscopic appearance of the black powdery PbS is porous nanosheet.

Embodiment 3

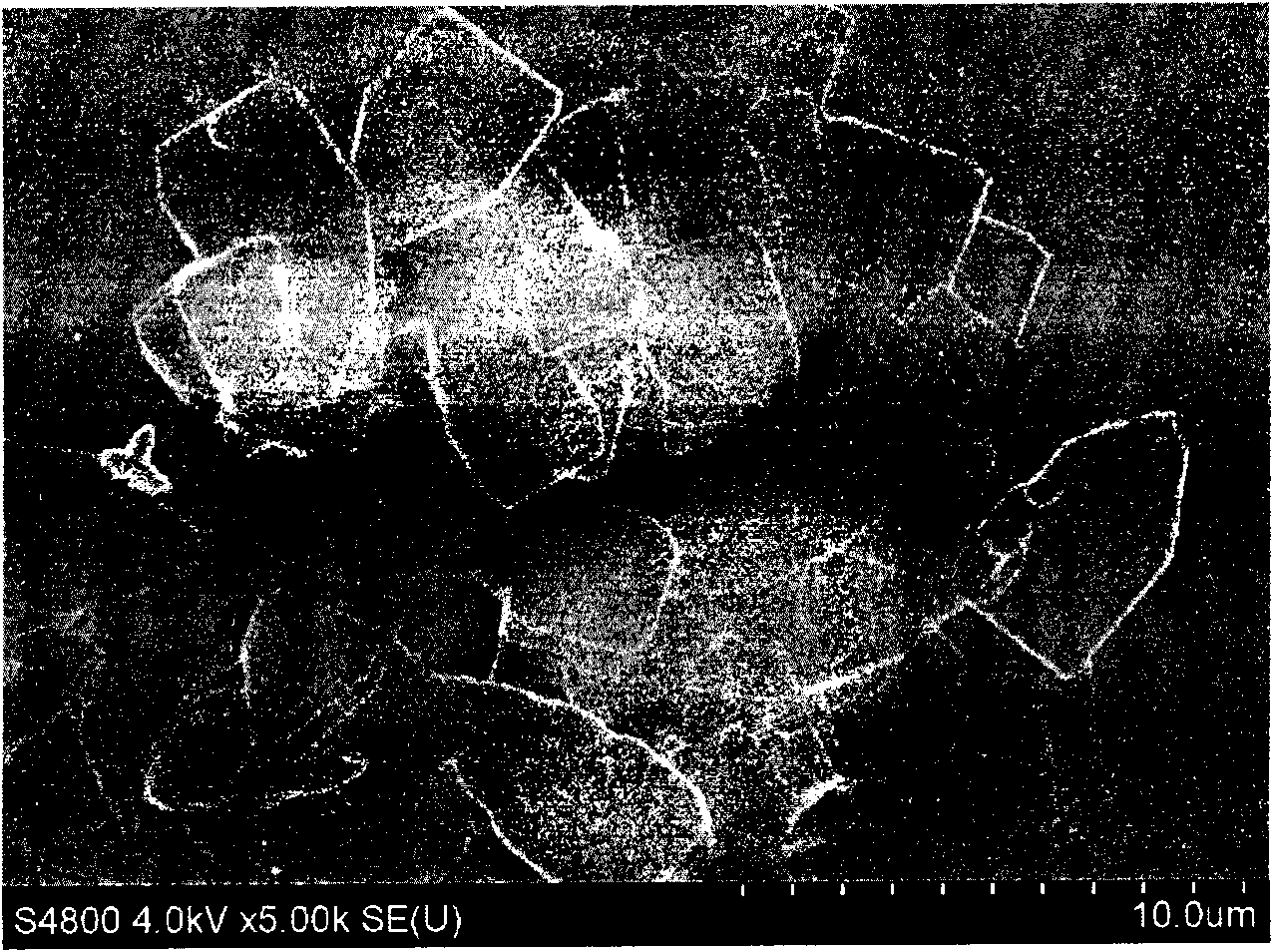

[0038] Embodiment 3: the preparation of porous PbS nano sheet material

[0039] Add 19.8-39.5μL of mercaptopropionic acid to 15mL of 0.01M lead perchlorate aqueous solution, and a white precipitate is produced immediately. Adjust the pH to 8-13 with aqueous sodium hydroxide solution and hydrochloric acid. Put the prepared reaction solution in a constant temperature box at 37°C and let it stand. After a large amount of white precipitate is formed, centrifuge and wash it with secondary water for 3 times at a speed of 8000-15000 rpm to obtain lead mercaptopropionate with a nanosheet structure. looks like image 3 shown.

[0040] Move the resulting lead mercaptopropionate to 0.001-1 M with 500 mL of Na 2 In S aqueous solution, react at 37°C for 0.1-3h, filter and separate, and dry in a vacuum oven to obtain black powder PbS, whose appearance is as follows: Figure 4 As shown, it is porous nanosheet.

[0041] Weigh 0.01-0.1 g of the obtained black PbS powder, place it in a 20 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com