Novel halogen-free flame-retardant reinforcing polyester alloy (ETP)

A polyester alloy, a new type of technology, applied in the field of modified polymer materials, can solve the problems of unreachable, poor flame retardant effect, etc., and achieve high environmental protection level, good flame retardant effect, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

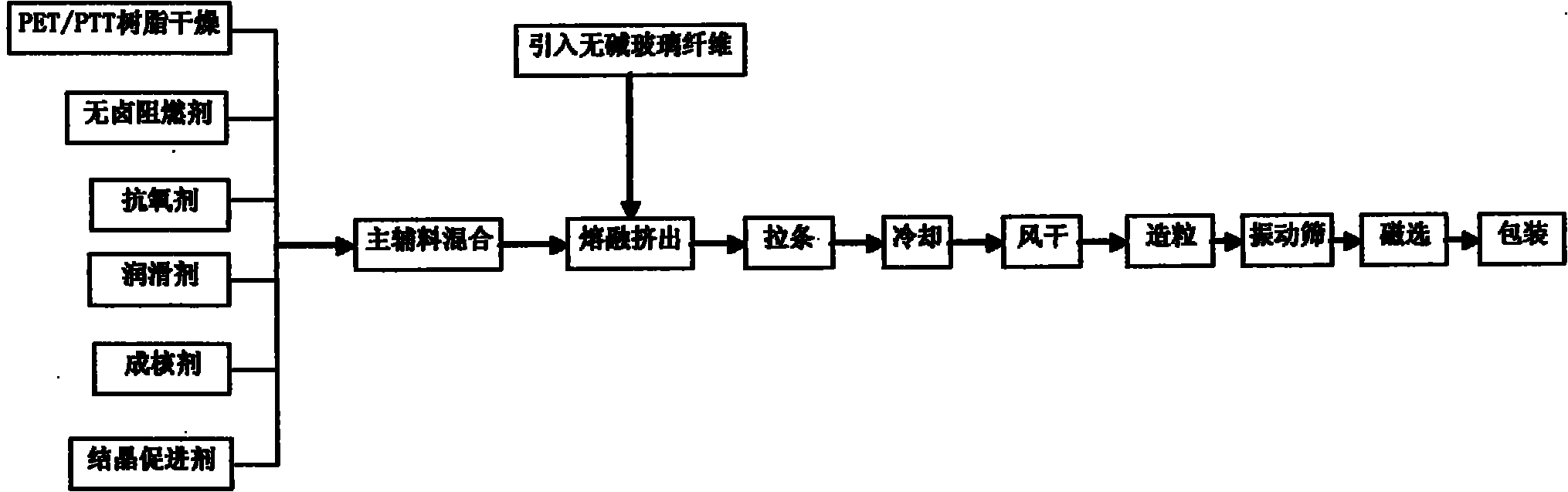

Method used

Image

Examples

Embodiment 1

[0052] New halogen-free flame retardant reinforced polyester alloy (ETP) formula (weight percent):

[0053] Ingredients:

[0054] (1) Polyethylene terephthalate (PET) 48%;

[0055](2) Polytrimethylene terephthalate (PTT) 16%;

[0056] Accessories:

[0057] (1) Halogen-free flame retardant

[0058] PDPTP 20%;

[0059] (2) Antioxidant

[0060] Antioxidant 1010 0.2%;

[0061] Antioxidant 168 0.2%;

[0062] (3) lubricant

[0063] TAF 0.4%;

[0064] (4) Nucleating agent

[0065] Nano bentonite 2%;

[0066] (5) Crystallization accelerator

[0067] Polyether 4%;

[0068] (6) enhancer

[0069] E-glass fiber 10%.

[0070] The performance of this embodiment is as follows: tensile strength=121Mpa, notched impact strength=60J / m, bending strength=180Mpa, flame retardant UL94 V0 level.

Embodiment 2

[0072] New halogen-free flame retardant reinforced polyester alloy (ETP) formula (weight percent):

[0073] Ingredients:

[0074] (1) Polyethylene terephthalate (PET) 40%;

[0075] (2) Polytrimethylene terephthalate (PTT) 15%;

[0076] Accessories:

[0077] (1) Halogen-free flame retardant

[0078] PDPTP 12%;

[0079] (2) Antioxidant

[0080] Antioxidant 1010 0.2%;

[0081] Antioxidant 168 0.2%;

[0082] (3) lubricant

[0083] TAF 0.6%;

[0084] (4) Nucleating agent

[0085] Nano bentonite 1%;

[0086] (5) Crystallization accelerator

[0087] Polyether 2%;

[0088] (6) enhancer

[0089] E-glass fiber 30%.

[0090] The performance of this embodiment is as follows: tensile strength=132Mpa, notched impact strength=75J / m, bending strength=212Mpa, flame retardant UL94 V0 level.

Embodiment 3

[0092] New halogen-free flame retardant reinforced polyester alloy (ETP) formula (weight percent):

[0093] Ingredients:

[0094] (1) Polyethylene terephthalate (PET) 45%;

[0095] (2) Polytrimethylene terephthalate (PTT) 16%;

[0096] Accessories:

[0097] (1) Halogen-free flame retardant

[0098] PDPTP 14%;

[0099] (2) Antioxidant

[0100] Antioxidant 1010 0.2%;

[0101] Antioxidant 168 0.2%;

[0102] (3) lubricant

[0103] TAF 0.5%;

[0104] (4) Nucleating agent

[0105] Nano bentonite 2%;

[0106] (5) Crystallization accelerator

[0107] Polyether 3%;

[0108] (6) enhancer

[0109] E-glass fiber 20%.

[0110] The performance of this embodiment is as follows: tensile strength=126Mpa, notched impact strength=68J / m, bending strength=195Mpa, flame retardant UL94 V0 level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com