Heating and temperature detecting method in tea processing

A tea and heating coil technology, applied in induction heating, induction heating control, induction heating device and other directions, can solve the problems of low energy utilization rate, low degree of cleaning, high use cost, shorten the preheating time, and achieve energy conversion efficiency. The effect of high and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

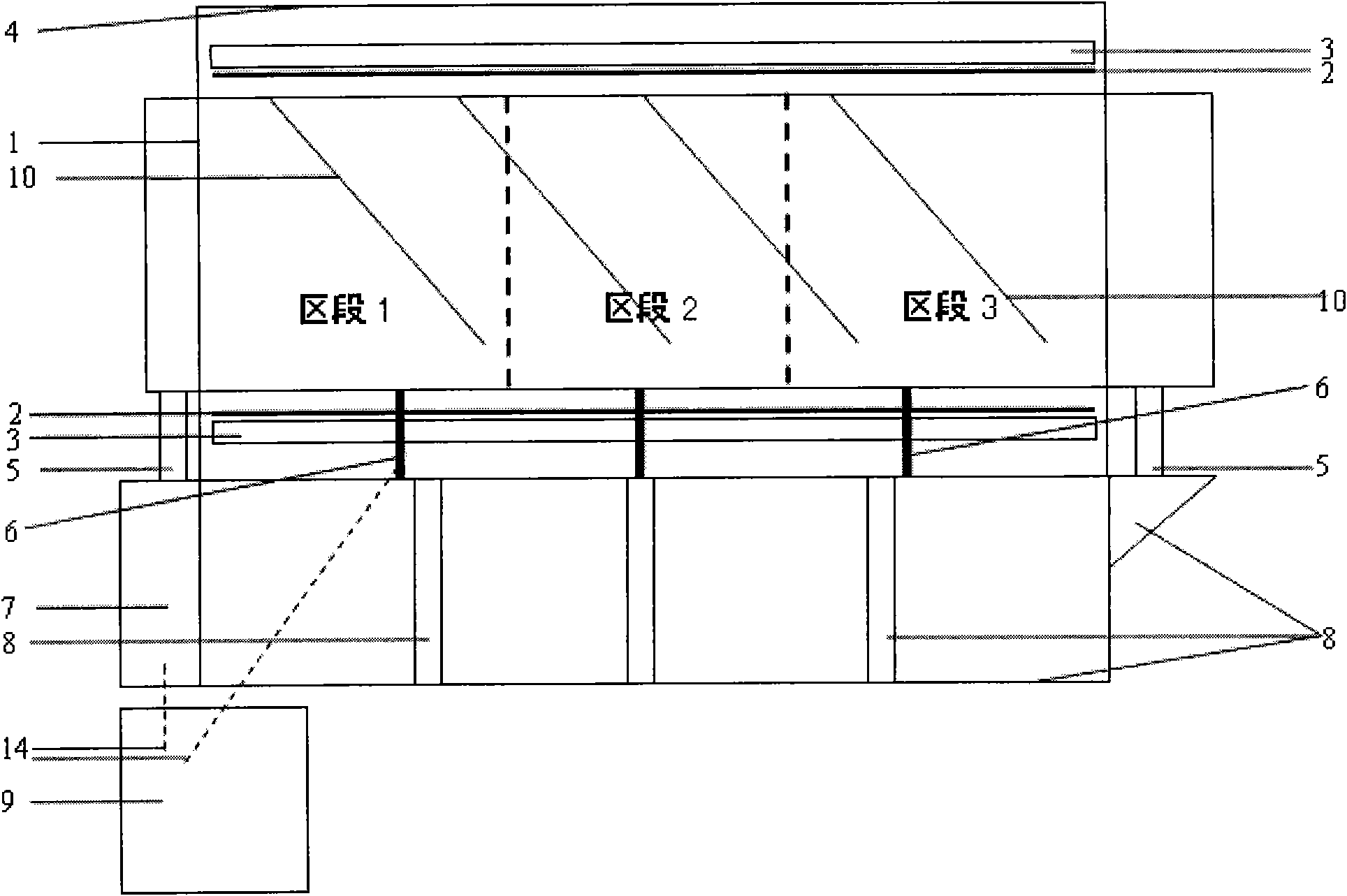

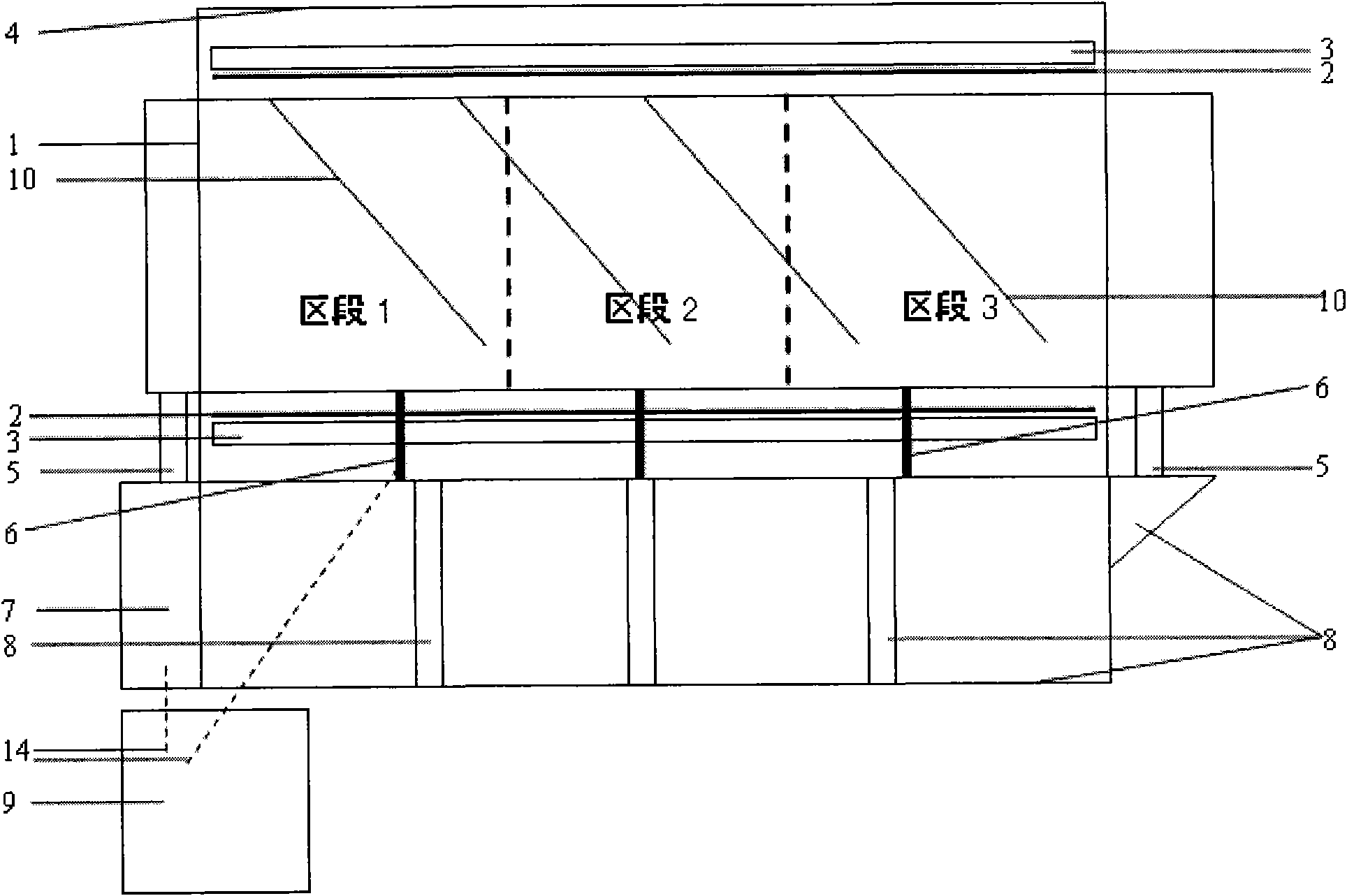

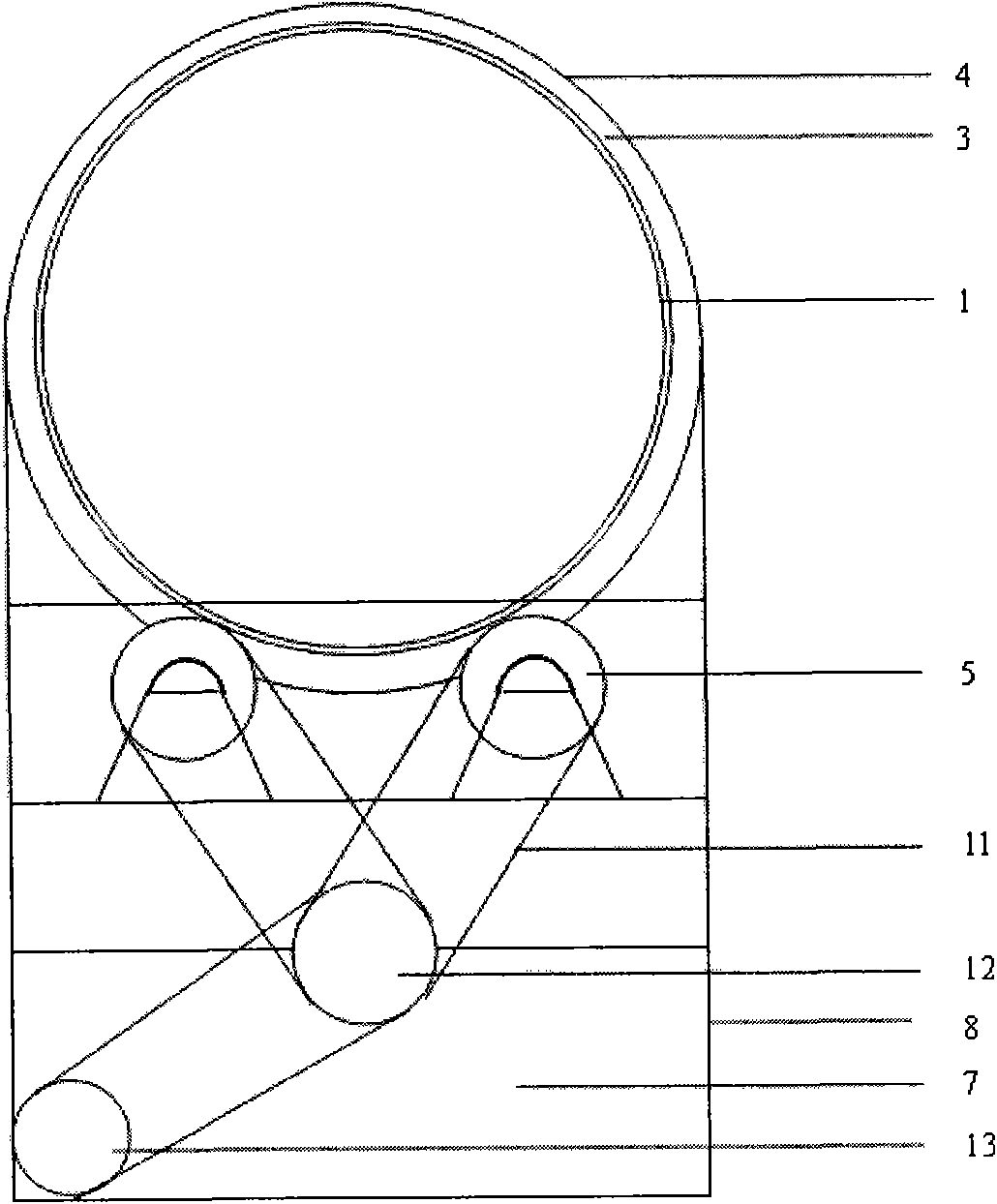

[0023] See Figures 1 and 2. The electromagnetic drum cleaning machine of the present invention consists of a steel cylinder 1, a heating coil 2, a heat insulating material 3, a decorative plate 4, a guide wheel 5, a far-infrared temperature sensor 6, a transmission device 7, a frame 8, an electric control cabinet 9, and guide vanes The outer layer of the steel cylinder 1 is covered with a heating coil 2, the inside of the steel cylinder 1 is welded with a guide vane 10, and the outer layer of the heating coil 2 is wrapped with a heat insulating material 3, and the outermost layer is passed through The decorative plate 4 fixed on the frame 8 by screws forms the main structure of the electromagnetic drum cleaning machine. The guide wheel 5 is connected with the transmission device 7, and the two are connected by a chain 11 to realize the transmission of power from the transmission device 7 to the main structure. , to promote the rotation of the steel cylinder 1, the transmission...

Embodiment 2

[0026] Referring to Fig. 1, during actual operation, during the rotation of the drum 1, the temperature of the three sections of the steel drum 1 can be set respectively through the main control cabinet 9, and the temperature of the three sections of the steel cylinder 1 can be set through the far-infrared temperature sensor 6 of each section. Monitor and feed back to the electric control cabinet 9 to realize the precise control of the temperature of the three sections of the steel cylinder 1 to meet the needs of fresh leaves of different varieties and tenderness.

Embodiment 3

[0027] Embodiment 3 comprehensive performance comparison:

[0028] 1. Taking the drum-type greening equipment as an example, comprehensively compare the performance differences of different heating methods:

[0029] heating

[0030] heating

[0031] 2. Combining electromagnetic heating technology with far-infrared temperature measurement technology, compared with the combination of traditional secondary heating and thermocouple temperature sensing technology, it can not only increase the heat conversion rate by about 30% in the heating link, but also because of the use of far-infrared temperature measurement Technology, more rapid and more accurate response to the temperature of the heated object, narrowing the temperature fluctuation range of the heated object, so that energy can be saved by 1-5% in the temperature control link. In addition, the organic combination of electromagnetic heating and far-infrared temperature measurement enables precise temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com