Method for catalyzing, esterifying and upgrading bio-oil under microwave condition

A bio-oil and condition technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve harsh reaction conditions, difficult operation, and high equipment quality requirements problem, to achieve the effect of improving stability and reducing the content of acid substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of catalyst: the Na that buys in the market + Type 732 cation exchange resin is washed with deionized water until clear water flows out, soaked in 4% NaOH for 4-8 hours, then washed with deionized water until neutral, then soaked in 4% HCl for 4-8 hours, washed with deionized water to pH = 6, dry at low temperature to obtain H + Type 732 strong acid ion exchange resin. Get a certain amount of zinc chloride and deionized water to make a mass concentration of 0.15% ZnCl 2 solution, adding H + Type 732 strongly acidic cation exchange resin carrier, impregnated with modified solution at room temperature for ion exchange, and finally washed with deionized water until Cl-free - So far (with 1% AgNO 3 indicator), dried to constant weight in a vacuum oven to obtain the ZnCl used in the experiment 2 Modified 732 type cation exchange resin catalyst expressed as 0.15% Zn 2+ / 732 resin catalyst.

[0025] 0.15% Zn 2+ / 732 resin catalyst is used in the method ...

Embodiment 2

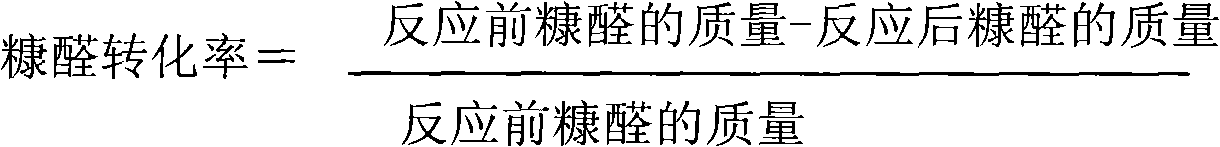

[0032] Reactant and consumption thereof are identical with embodiment 1, and catalyst is 1.5gZn 2+ / 732 resin, five sets of reactions were performed at reaction temperatures of 45°C, 55°C, 65°C, 75°C, and 85°C, and the activity evaluation conditions were the same as in Example 1 except for the reaction temperature conditions. The results are shown in Table 2.

[0033] Table 2 Microwave esterification reaction results of ethanol, acetic acid and furfural at different temperatures

[0034] temperature / ℃

Embodiment 3

[0036] Reactant and its consumption are identical with embodiment 1, do five groups of reactions under catalyst consumption 0.2g, 0.5g, 0.75g, 1.0g, 1.5g conditions respectively (the mass ratio of corresponding catalyst and reactant is respectively 1: 154.5 . The results are shown in Table 3.

[0037] Table 3 Microwave esterification reaction results of ethanol, acetic acid and furfural under different catalyst dosage

[0038] Catalyst dosage / g

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com