Preparation method and application of catalyst used in hydrogenation of silicon tetrachloride

A technology of silicon tetrachloride and catalyst, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, silicon organic compounds, etc., can solve the problems of low catalytic efficiency and achieve high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

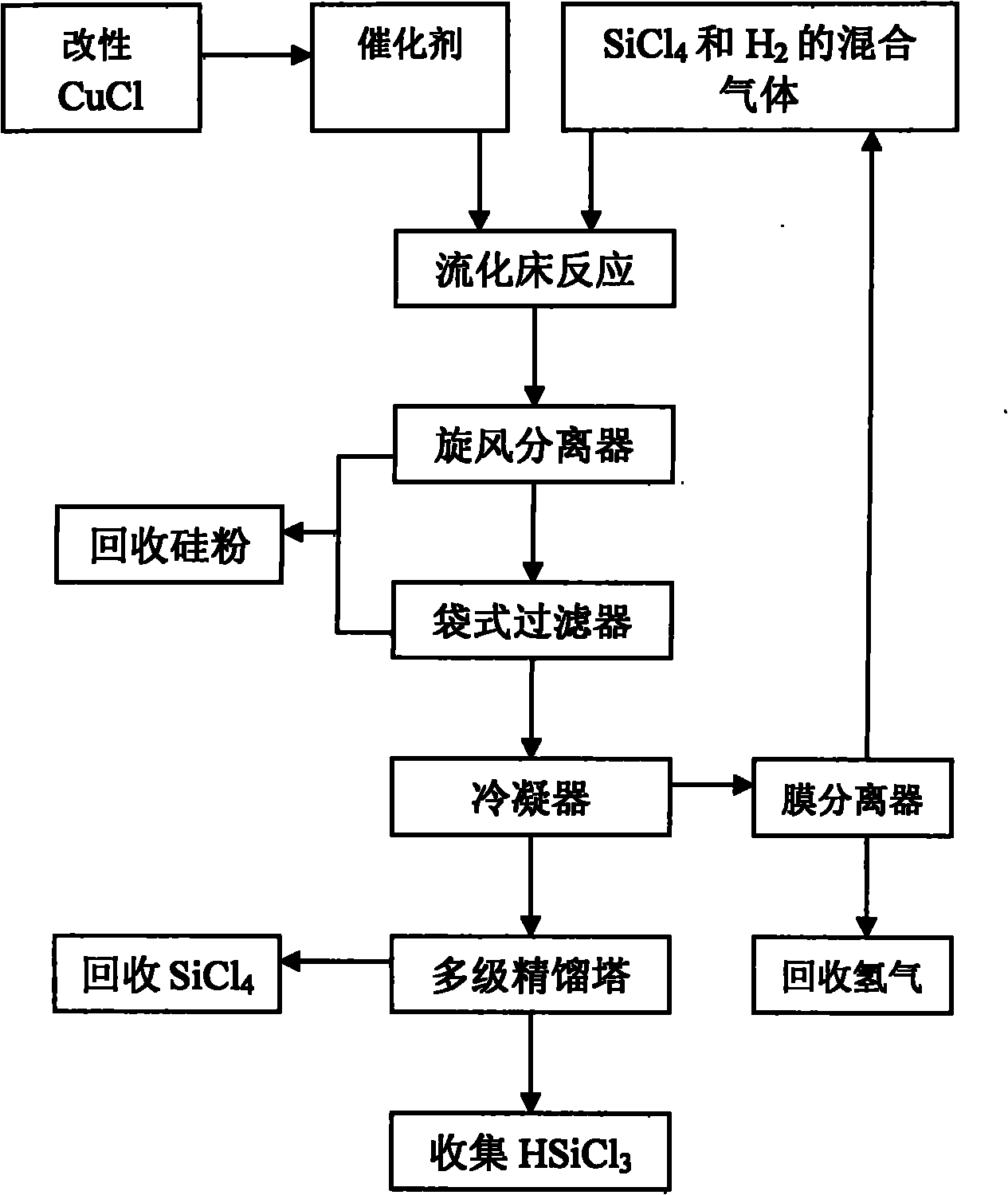

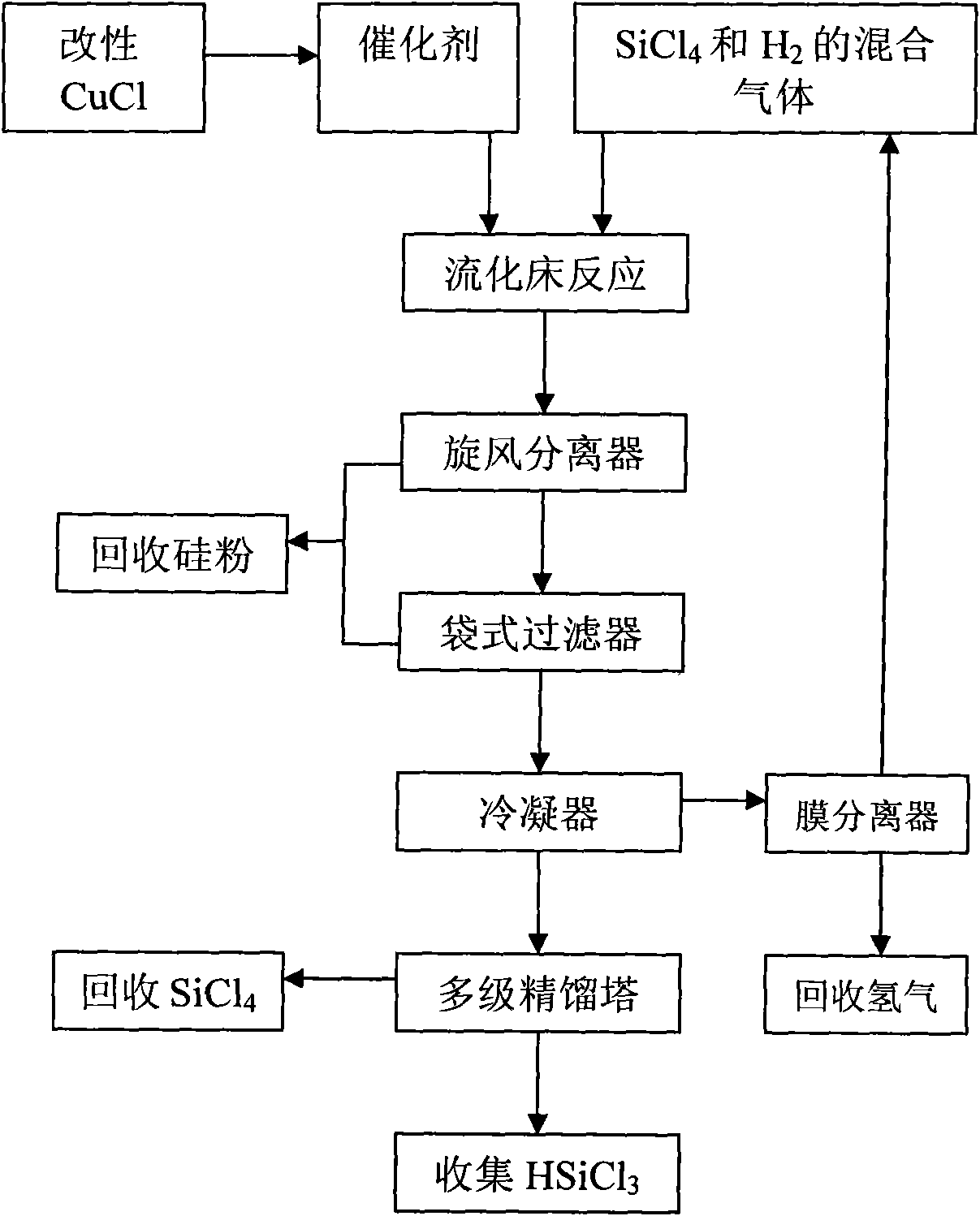

Method used

Image

Examples

preparation example Construction

[0011] A preparation method for a catalyst for the hydrogenation of silicon tetrachloride, comprising:

[0012] Mix the pretreated cuprous chloride and silicon powder in a stirred bed reactor, and heat the reaction under hydrogen; the pretreatment refers to adding cuprous chloride to silicon tetrachloride, stirring and heating, and filtering Dry under protective gas.

[0013] The average particle size of the cuprous chloride is preferably 2-7 μm.

[0014] Wherein, the molar ratio of silicon tetrachloride to cuprous chloride is preferably 1:1-2:1. This can not only ensure the sufficient dispersion of cuprous chloride, but also avoid wasting too much silicon tetrachloride and affecting the subsequent treatment.

[0015] Wherein, the stirring and heating in the pretreatment is well known to those skilled in the art. In the present invention, the temperature is preferably controlled at 40-50° C., the stirring speed is 60-300 rpm, and the stirring and heating time is 20-40 minute...

Embodiment 1

[0046] Liquid SiCl 4 CuCl with an average particle size of 2 μm was added into the stirred reactor at a molar ratio of 1:1, and it was heated to 40° C. and fully stirred for 20 minutes. After filtering, the filtered CuCl was heated to 80° C. and dried for 10 min under the condition of blowing nitrogen gas.

[0047] Dried CuCl and metallurgical grade silicon powder (silicon purity: 98%) with an average particle size of 190 μm were added to the stirred bed reactor and mixed, and CuCl accounted for 0.75% of the mass of the silicon powder. The added amount of metal powder aluminum in the stirred bed reactor is 1wt% of CuCl. The above mixture was heated to 280° C. for 50 min under the condition of feeding hydrogen. Prepare copper-silicon alloy catalyst A1.

[0048] SiCl 4 and H 2 After heating to 400°C, it is charged into a gas mixing device with a molar ratio of 1:2 for pre-mixing to form a mixed gas. Add the mixed gas and catalyst A1 into the fluidized bed reactor, keep the...

Embodiment 2

[0053] Liquid SiCl 4 CuCl with an average particle size of 4 μm was added into the stirred reactor at a molar ratio of 1.5:1, and it was heated to 45° C. and fully stirred for 30 minutes. After filtering, the filtered CuCl was heated to 90° C. and dried for 30 minutes under the condition of blowing nitrogen gas.

[0054] Dried CuCl and metallurgical grade silicon powder (silicon purity: 98.5%) with an average particle size of 200 μm were mixed into the stirred bed reactor, and CuCl accounted for 1% of the mass of the silicon powder. The addition amount of metal powder zinc in the stirred bed reactor is 5wt% of CuCl. The above mixture was heated to 350° C. for 70 min under the condition of feeding hydrogen. Prepare copper-silicon alloy catalyst A2.

[0055] SiCl 4 and H 2 After heating to 450°C, it is charged into a gas mixing device with a molar ratio of 1:4 for pre-mixing to form a mixed gas. Add the mixed gas and catalyst A2 into the fluidized bed reactor, keep the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com