Method for synthesizing calcium arsenate by oxygen pressure conversion

A technology for synthesizing calcium arsenate and calcium arsenate, which is applied in chemical instruments and methods, separation methods, arsenate/arsenite, etc., can solve the problems of low reagent consumption, fast reaction speed, and short time, etc. Achieve the effect of less reagent consumption, fast reaction speed and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

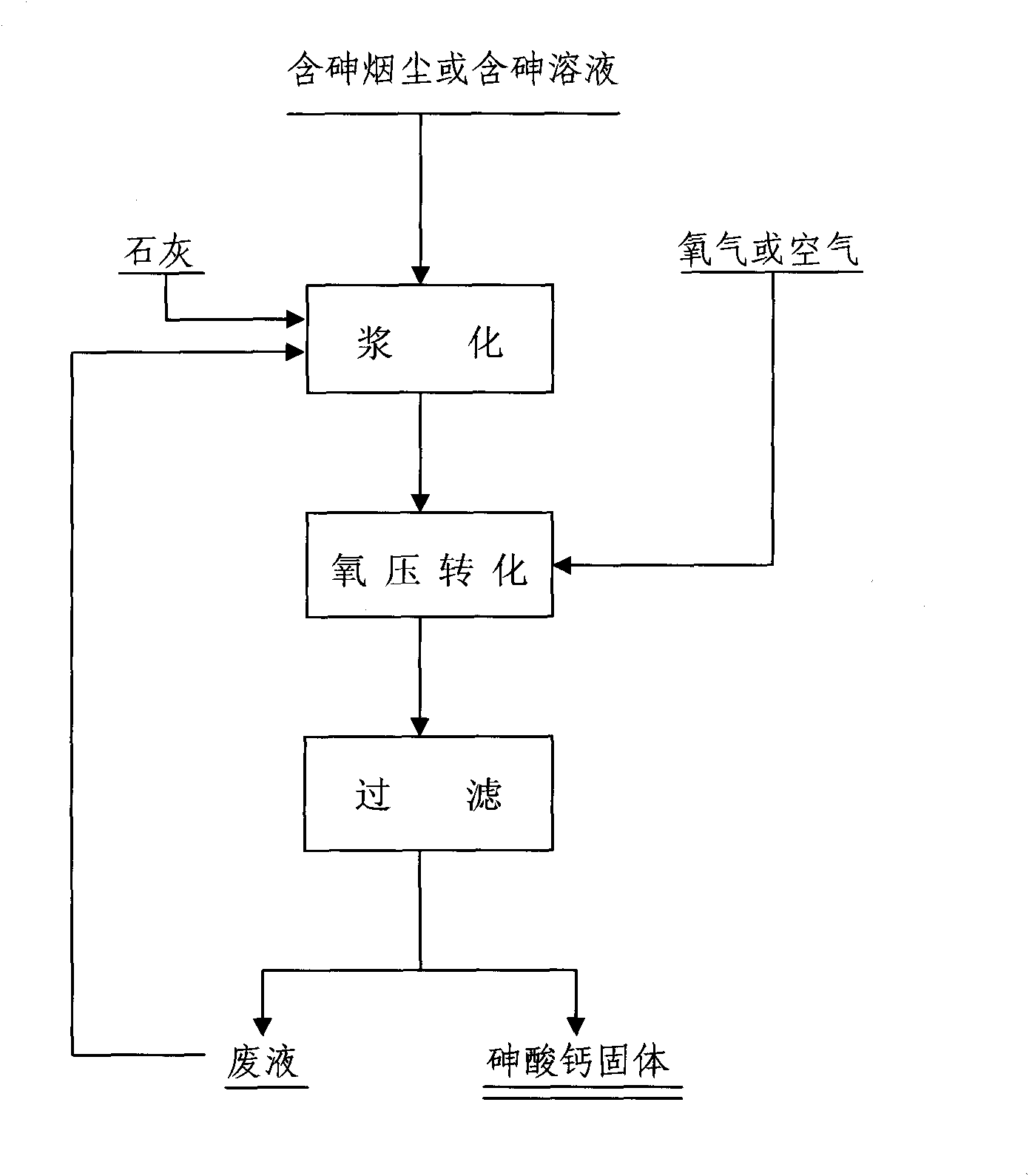

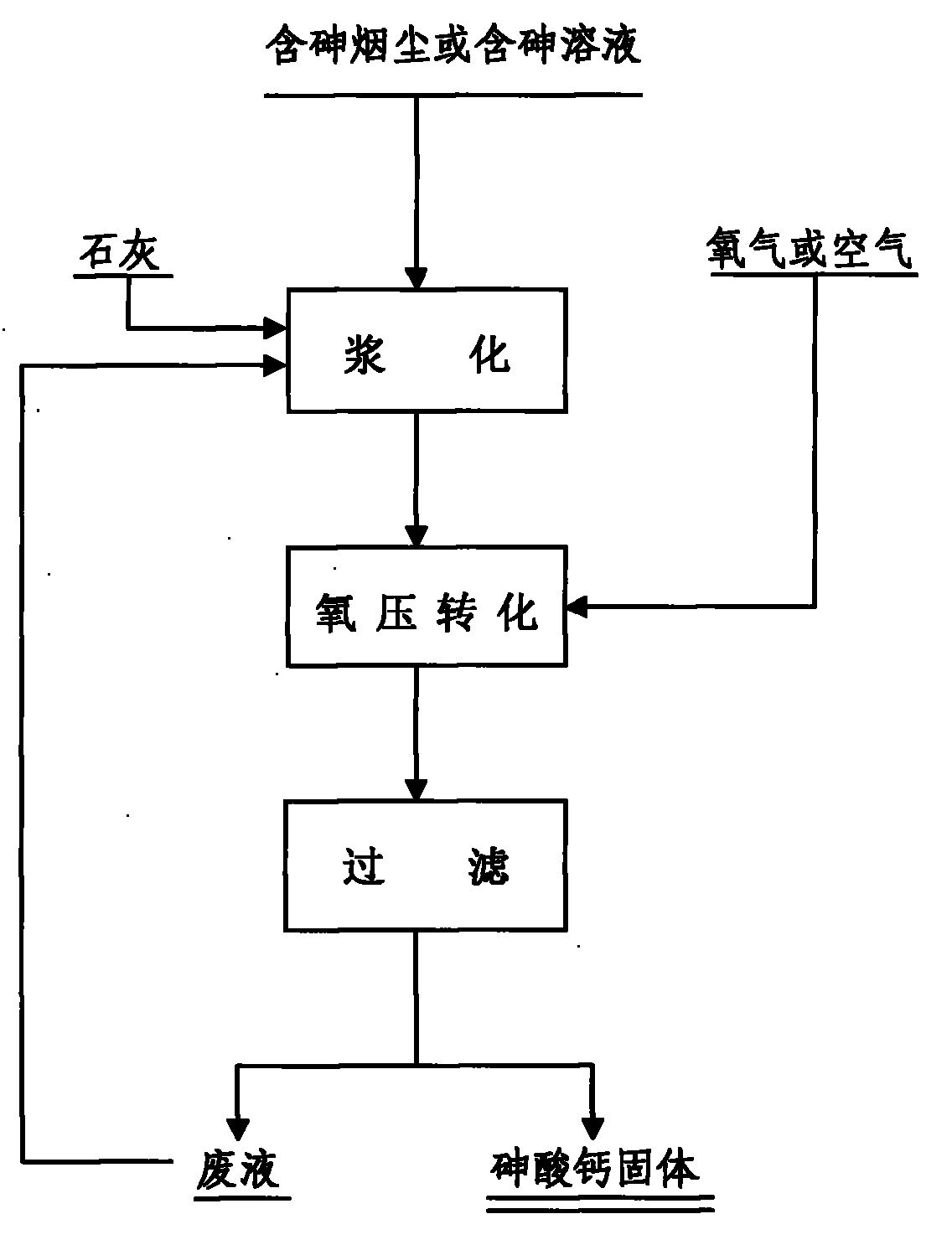

Image

Examples

Embodiment 1

[0024] The soot contains 48.34% arsenic. Add 1Kg of arsenic-containing soot into 8Kg of water, add lime that is 1.5 times the theoretical requirement of arsenic, stir and slurry for 1 hour, then put the slurried material into a closed stirring reactor, heat to 150°C, and pass in oxygen until it is airtight The oxygen partial pressure in the container was 1.0 MPa, and the reaction was stirred for 2 hours. The reacted material is cooled and filtered to obtain stable calcium arsenate solid.

Embodiment 2

[0026] The soot contains 32.84% arsenic. Add 1Kg of arsenic-containing soot into 5Kg of water, add lime that is 2.0 times the theoretical requirement of arsenic, stir and slurry for 1 hour, then put the slurried material into a closed stirring reactor, heat to 180°C, and pass in oxygen until it is airtight The oxygen partial pressure in the container was 0.6 MPa, and the reaction was stirred for 3 hours. The reacted material is cooled and filtered to obtain stable calcium arsenate solid.

Embodiment 3

[0028] The soot contains 67.42% arsenic. Add 1Kg of arsenic-containing soot into 10Kg of water, add lime that is 1.1 times the theoretical requirement of arsenic, stir and slurry for 1 hour, then put the slurried material into a closed stirring reactor, heat to 120°C, and pass in oxygen until it is airtight The oxygen partial pressure in the container was 1.5 MPa, and the reaction was stirred for 2 hours. The reacted material is cooled and filtered to obtain stable calcium arsenate solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com