Method for treating coking wastewater biologically

A technology of coking wastewater and biological method, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of low nitrate nitrogen concentration in denitrification rate, achieve high denitrification rate, volume Small, low-concentration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention relates to a biological method for treating coking wastewater. The water quality of coking wastewater after homogenization, oil separation and air flotation pretreatment is: COD, NH 3 The mass concentrations of -N, phenol and cyanide are 2500-2800 mg / L, 200-250 mg / L, 600-800 mg / L and 25-35 mg / L, respectively.

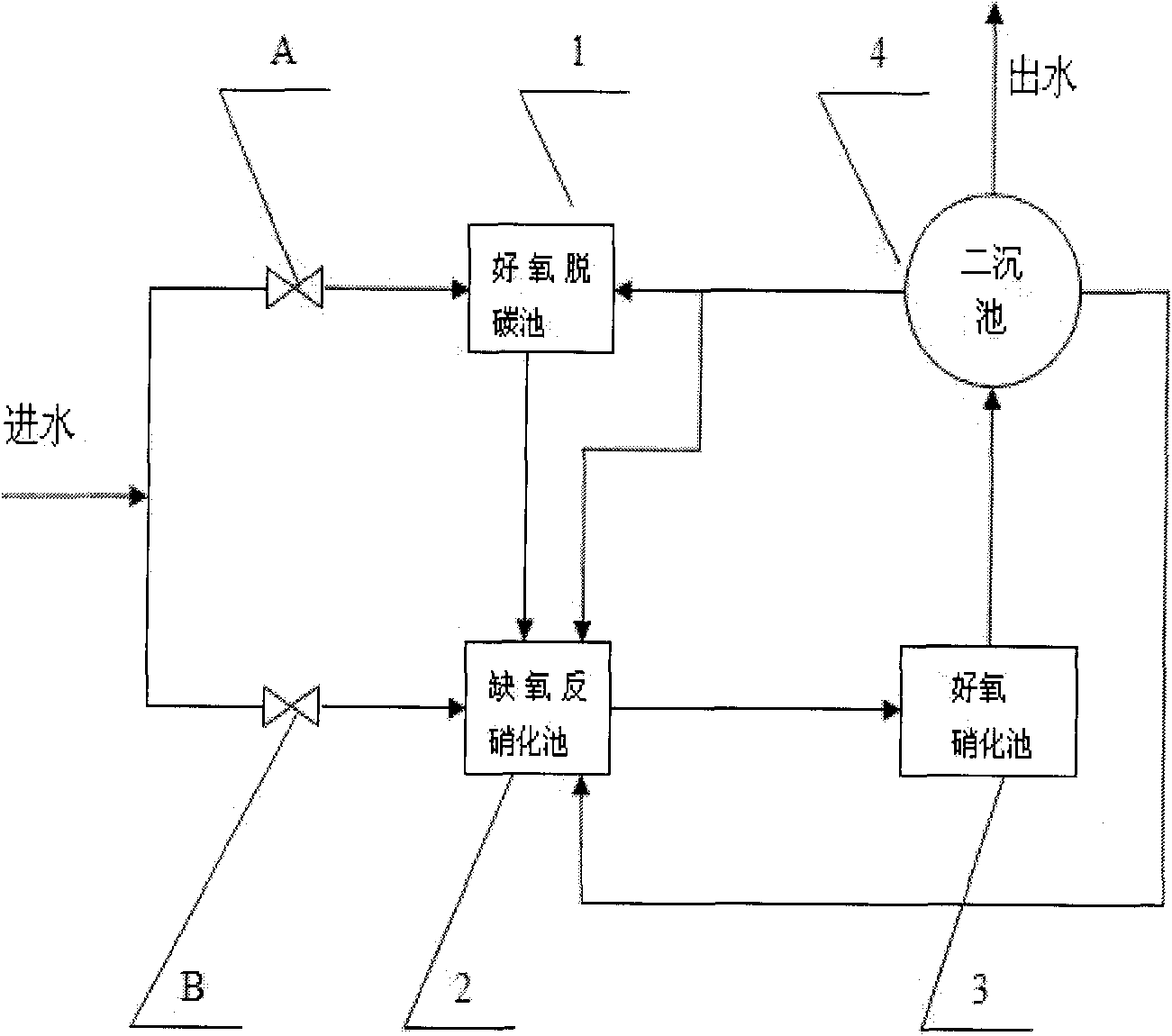

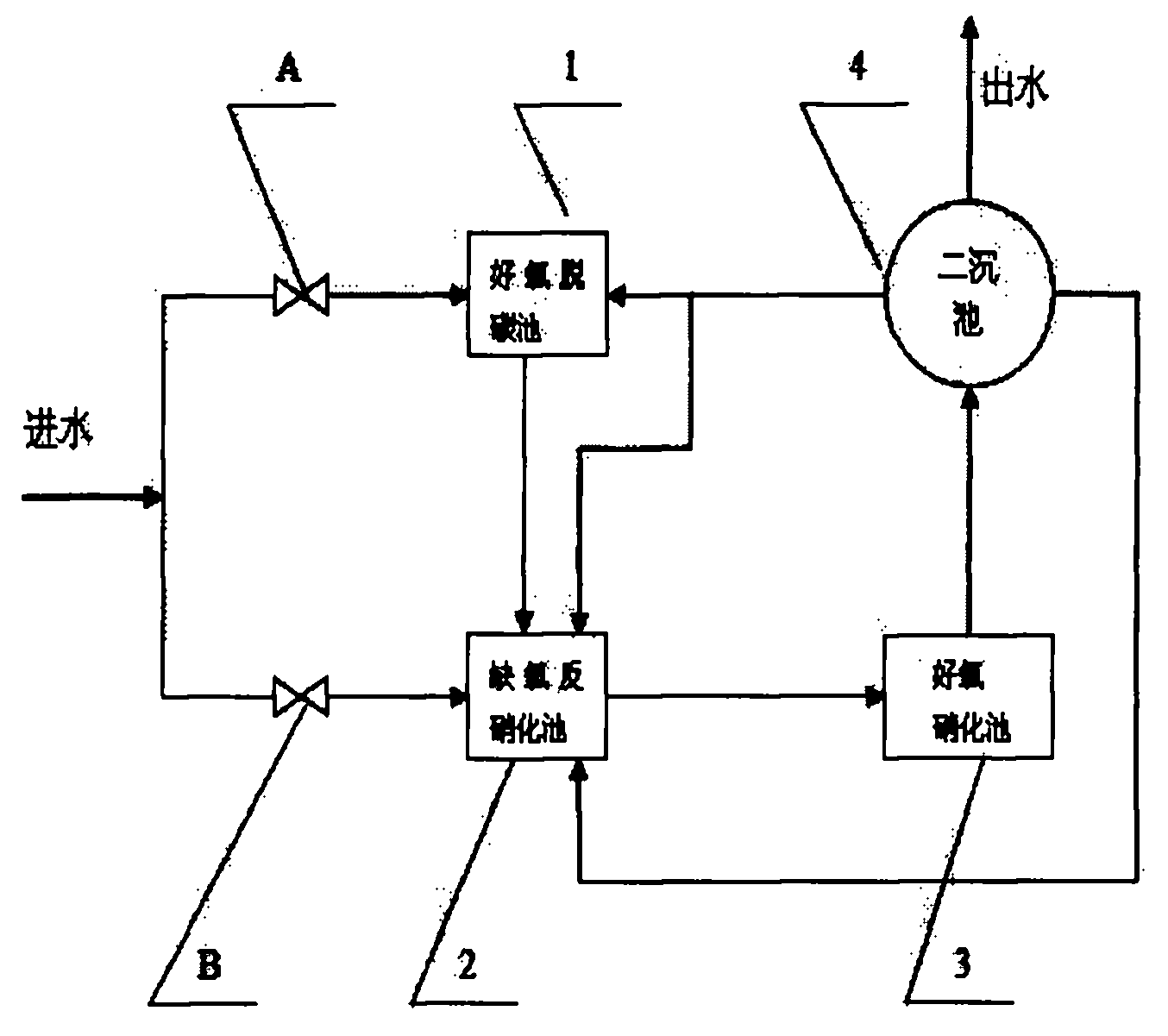

[0022] Its process is as figure 1 As shown, in terms of volume percentage, 30% to 40% of the pretreated coking wastewater is controlled by valve A and enters the aerobic decarbonization pool 1 for decarburization, and stays for 6.5 to 7.5 hours; Oxygen denitrification pool 2, at the same time, 60% to 70% of the pretreated coking wastewater enters the anoxic denitrification pool 2 through valve B, and stays for 22 to 25 hours; 3 Continuously add sodium carbonate solution to neutralize the acid produced in the nitrification process, and the residence time is 20-25 hours; then enter the secondary sedimentation tank 4 for precipitation for 2-3 hours, ...

Embodiment 2

[0026] The invention relates to a biological method for treating coking wastewater. The water quality of coking wastewater after homogenization, oil separation and air flotation pretreatment is: COD, NH 3 The mass concentrations of -N, phenol and cyanide are 2800-3200 mg / L, 250-300 mg / L, 700-900 mg / L and 25-40 mg / L, respectively.

[0027] Its process is as figure 1 As shown, in terms of volume percentage, first 40% to 50% of the pretreated coking wastewater is controlled by valve A and enters the aerobic decarbonization pool 1 for decarburization and stays for 7 to 10 hours; after decarburization, it enters anoxic Denitrification pool 2, at the same time, 50% to 60% of pretreated coking wastewater enters anoxic denitrification pool 2 through valve B, and stays for 20 to 22 hours; Continuously add sodium carbonate solution to neutralize the acid generated in the nitrification process, and the residence time is 24-27h. Then enter the secondary settling tank 4. All the other ...

Embodiment 3

[0030]The invention relates to a biological method for treating coking wastewater. The water quality of coking wastewater after homogenization, oil separation and air flotation pretreatment is: COD, NH 3 The mass concentrations of -N, phenol and cyanide are 3200-3500 mg / L, 300-350 mg / L, 800-1000 mg / L and 25-40 mg / L, respectively.

[0031] Its process is as figure 1 As shown, in terms of volume percentage, 50% to 60% of the pretreated coking wastewater is controlled by valve A and enters the aerobic decarbonization pool 1 for decarburization and stays for 9 to 12 hours; after decarburization, it enters anoxic Denitrification tank 2, at the same time, 40% to 50% of pretreated coking wastewater enters anoxic denitrification tank 2 through valve B, and stays for 18 to 20 hours; Continuously add sodium carbonate solution to neutralize the acid produced in the nitrification process, and the residence time is 25-30h. Then enter the secondary settling tank 4. All the other are wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com