Multi-optical fiber channel laser infrared gas sensor

A gas sensor and multi-fiber technology, applied in the field of infrared gas sensors, can solve the problems of strong heating, obvious delay, damage, etc., and achieve the effects of high detection sensitivity, improved integration, and good identifiability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

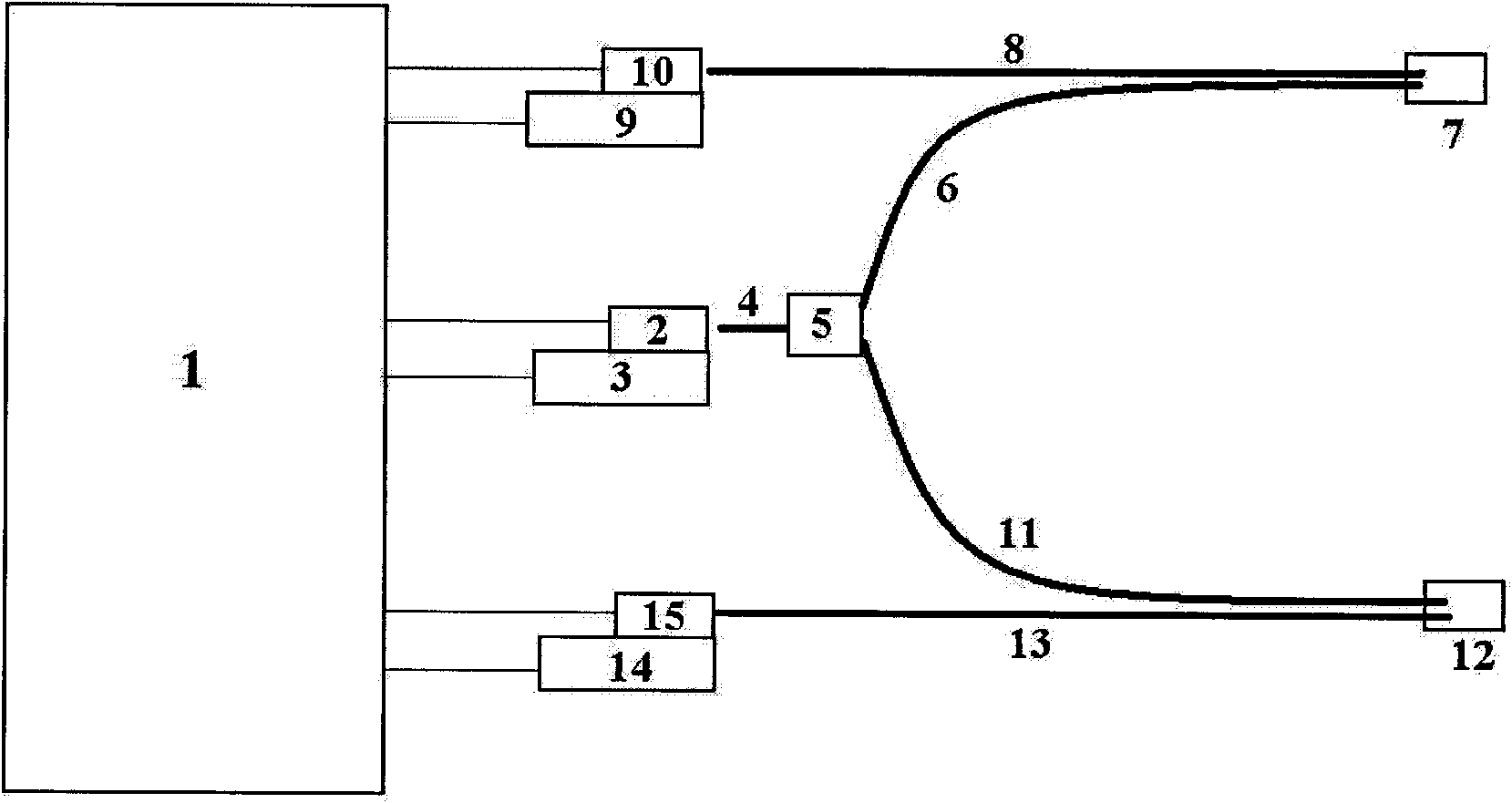

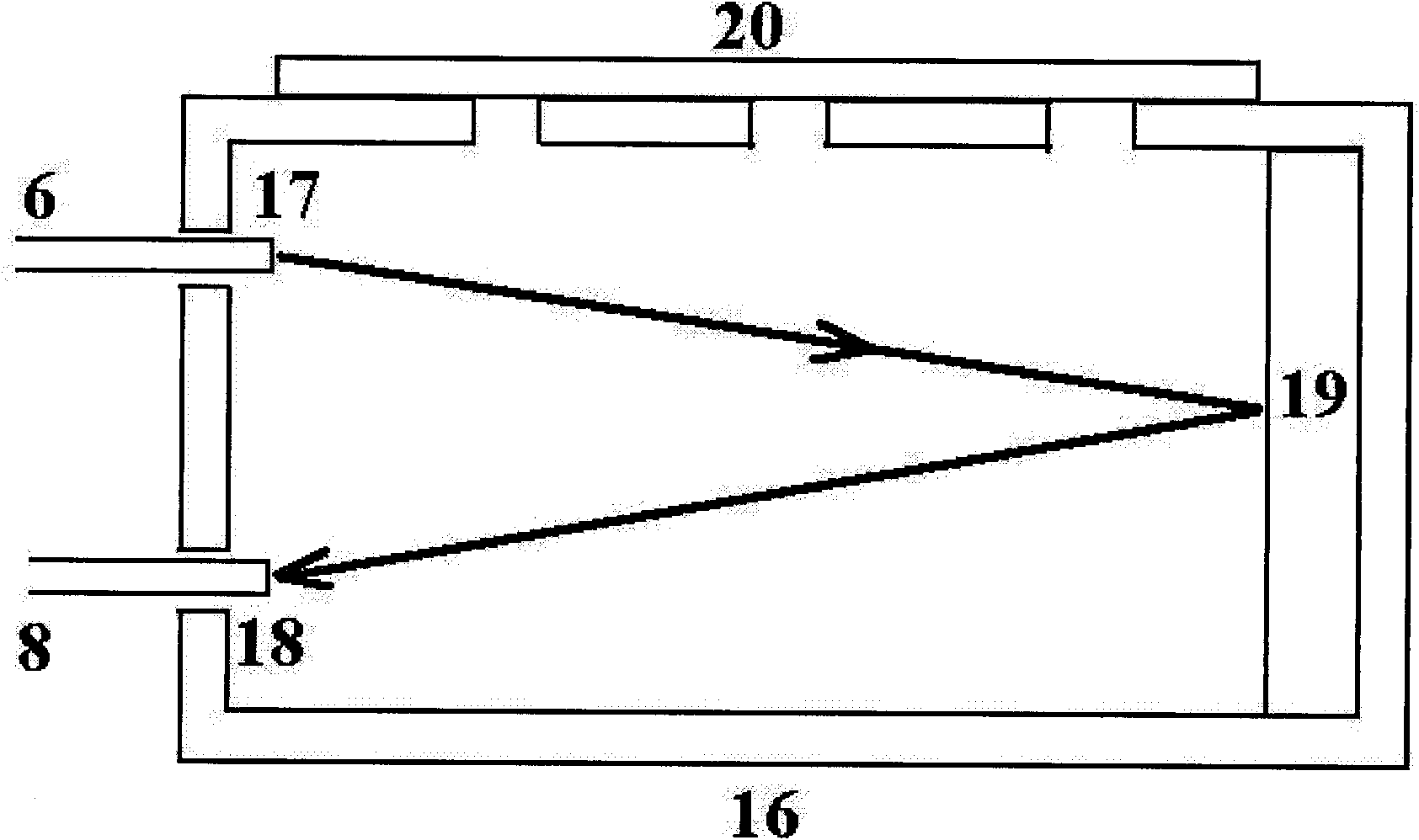

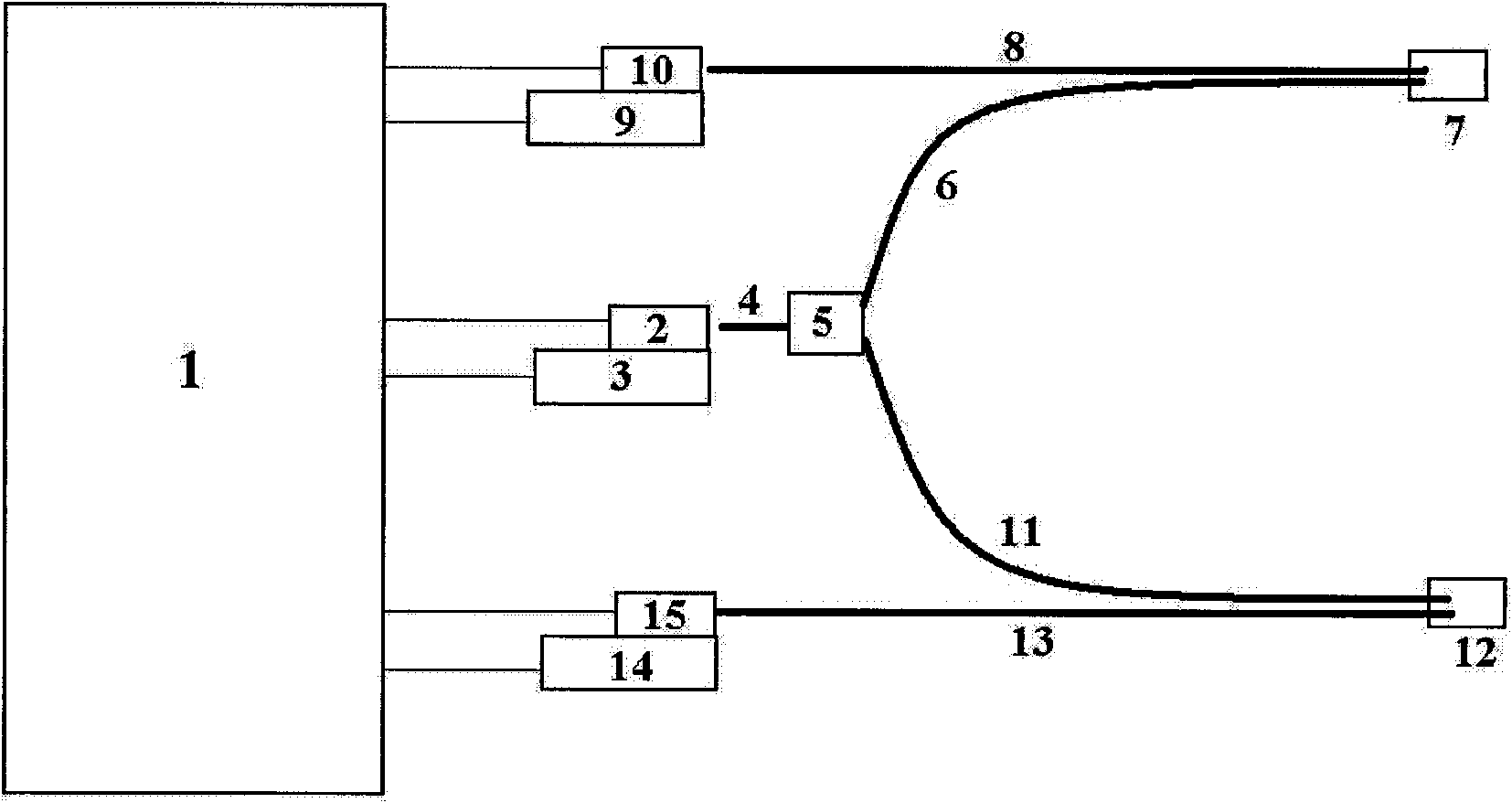

[0021] like figure 1 As shown, the multi-fiber channel (taking two fiber channels as an example) laser infrared gas sensor of the present invention includes: circuit and man-machine exchange module 1, used for power supply management, system control, phase-locked amplification, acquisition and storage of signals , analysis and reading, and human-computer interaction; the first semiconductor thermoelectric cooler 2 is connected with the circuit and the human-machine exchange module 1 for temperature control; the quantum cascade laser 3 is fixed on the first semiconductor thermoelectric cooler 2 and be connected with the circuit and the man-machine exchange module 1 for emitting infrared laser; the lens fiber 4 (the first optical fiber), near the light-emitting end of the quantum cascade laser, is used to collimate the infrared light emitted by the quantum cascade laser and Lead in optical fiber; fiber coupler 5, connect lens optical fiber 4, divide laser light into a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com