Preparation method of cigarette absorption type flavor compensation material

An adsorption-type, aroma-based technology, applied in tobacco, e-liquid filter elements, applications, etc., can solve the problems of limited tar reduction, non-existence, complex addition process, etc., and achieve the effect of stable crushing and not easy crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

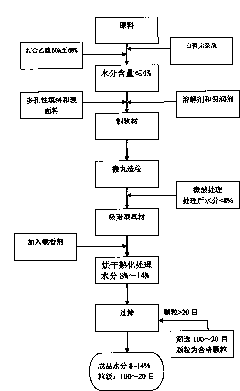

Method used

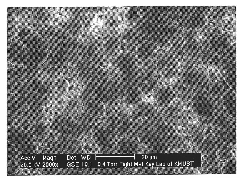

Image

Examples

Embodiment 1

[0031] Aroma compensating granules made by the following process

[0032] a. Material selection: cellulose acetate with moisture content ≤4%;

[0033] b. Mix 200 g of cellulose acetate, 650 g of acetone, and 150 g of propylene glycol, add them to the cellulose acetate, stir evenly, and store in airtight conditions at normal temperature and pressure for 3 hours to obtain a cellulose acetate solution;

[0034] c. Add 1kg of cellulose acetate solution prepared in b to 1kg of expanded silicate rock fine powder below 80 mesh, then add 300g of rush fine powder below 80 mesh, mix well and make it into a ball that can be lightly touched Instant soft materials, sealed for 3 hours;

[0035] d. Make the soft material obtained in step c into pellets of 20 to 60 meshes with a pellet machine, dry them quickly with microwaves, and then bake them with 40% firepower for 10 minutes to remove the lignin in the base material , that is, the adsorption substrate;

[0036] e. Extract grosvenoria ...

Embodiment 2

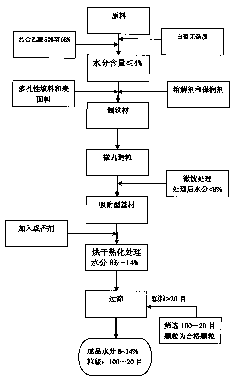

[0041] Aroma compensating granules made by the following process

[0042] a. Material selection: cellulose acetate with moisture content ≤4%;

[0043] b. Mix 400 g of cellulose acetate, 850 g of acetone, and 250 g of ethanol, add it to the cellulose acetate, stir evenly, and store it in airtight conditions at normal temperature and pressure for 1 hour to obtain a cellulose acetate solution;

[0044] c. Add 1 kg of cellulose acetate solution prepared in b to 1 kg of lignin fine powder below 80 mesh, and then add 300 g of rush fine powder below 80 mesh, mix evenly and make it into a ball that can be held and disperse when lightly touched. Soft materials, sealed for 3 hours;

[0045] d. Make the soft material obtained in step c into 20 to 60 mesh pellets with a pellet machine, dry them quickly with microwaves, and then bake them with 40% firepower for 10 minutes to remove the lignin in the substrate , that is, the adsorption substrate;

[0046] e. Extract grosvenoria grosvenor...

Embodiment 3

[0051] Aroma compensating granules made by the following process

[0052] a. Material selection: cellulose acetate with moisture content ≤4%;

[0053]b. Mix 400 g of cellulose acetate, 650 g of acetone, 250 g of ethanol, and 100 g of propylene glycol, add them to the cellulose acetate, stir evenly, and store in airtight conditions at normal temperature and pressure for 1 hour to obtain a cellulose acetate solution;

[0054] c. Add 1 kg of cellulose acetate solution prepared in b to 1 kg of plant cellulose (below 80 mesh) fine powder, then add 300 g of rush grass fine powder below 80 mesh, mix evenly and make it into a ball that can be lightly touched Instant soft materials, sealed for 3 hours;

[0055] d. Make the soft material obtained in step c into pellets of 20 to 60 meshes with a pellet machine, dry them quickly with microwaves, and then bake them with 40% firepower for 10 minutes to remove the lignin in the base material , that is, the adsorption substrate;

[0056] e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com