Modified bismaleimide-triazine resin and preparation method thereof

A technology of bismaleimide and triazine resin is applied in the field of high-performance resin and preparation thereof, modified bismaleimide-triazine resin and preparation thereof, and can solve the problem of being unfavorable for maintaining heat resistance of BT resin. It can prevent the problems of excellent flame retardancy of polysiloxane, and reduce the heat resistance of modified resin, so as to achieve the effect of excellent processing technology and phase structure, excellent water repellency, and outstanding heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] After weighing 1.98 g of deionized water and 19.8 g of phenyltrimethoxysilane and mixing them uniformly, slowly add 38% HCl dropwise at room temperature with stirring until the pH of the solution is 1. 10 minutes after the completion of the dropwise addition, the temperature was raised to 50°C to continue the reaction for 4 hours. After the reaction was completed, the methanol was evaporated by vacuum drying to obtain a transparent and viscous hyperbranched polysiloxane with phenyl as the terminal group. Its structural formula is:

[0031]

[0032] Wherein, R is a phenyl group, and Me is a methyl group.

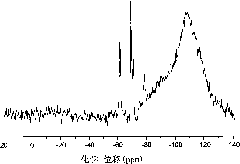

[0033] See attached figure 1 Shown, it is the hyperbranched polysiloxane of the present embodiment 29 Si-NMR spectrum. from figure 1 It can be seen that the synthesized polysiloxane has linear, terminal and branched units, and its branching degree is 0.40, which is a polysiloxane with a typical hyperbranched structure.

[0034] Weigh 1g of the above hyperbranch...

Embodiment 2

[0036] Prepare the hyperbranched polysiloxane with phenyl as the end group by the method of Example 1.

[0037] Weigh 5.3g of the above hyperbranched polysiloxane, 100.0g of bisphenol A type cyanate and 33.0g of diphenylmethane type bismaleimide, and mix them uniformly at 150°C to obtain the modified BT resin.

[0038] Pour the obtained modified BT resin into the preheated casting mold, vacuum defoam at 150°C for 2 hours, and then cure according to the process of 180°C / 2h+200°C / 2h+220°C / 2h+240°C / 4h And post-processing, demoulding after natural cooling, obtains cured modified BT resin. Some properties of cured resins are listed in Figure 2 ~ Figure 6 .

Embodiment 3

[0040] According to the method of Example 1, a hyperbranched polysiloxane with a phenyl group as an end group was prepared.

[0041] Weigh 10.6g of the above-mentioned hyperbranched polysiloxane, 100.0g of bisphenol A type cyanate and 33.0g of diphenylmethane type bismaleimide, and mix them uniformly at 150°C to obtain the modified BT resin.

[0042] Pour the obtained modified BT resin into the preheated casting mold, vacuum defoam at 150°C for 2 hours, and then cure according to the process of 180°C / 2h+200°C / 2h+220°C / 2h+240°C / 4h And post-processing, demoulding after natural cooling, obtains cured modified BT resin. Some properties of cured resins are listed in Figure 2 ~ Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com