High weatherability self-cleaning fluorocarbon coating

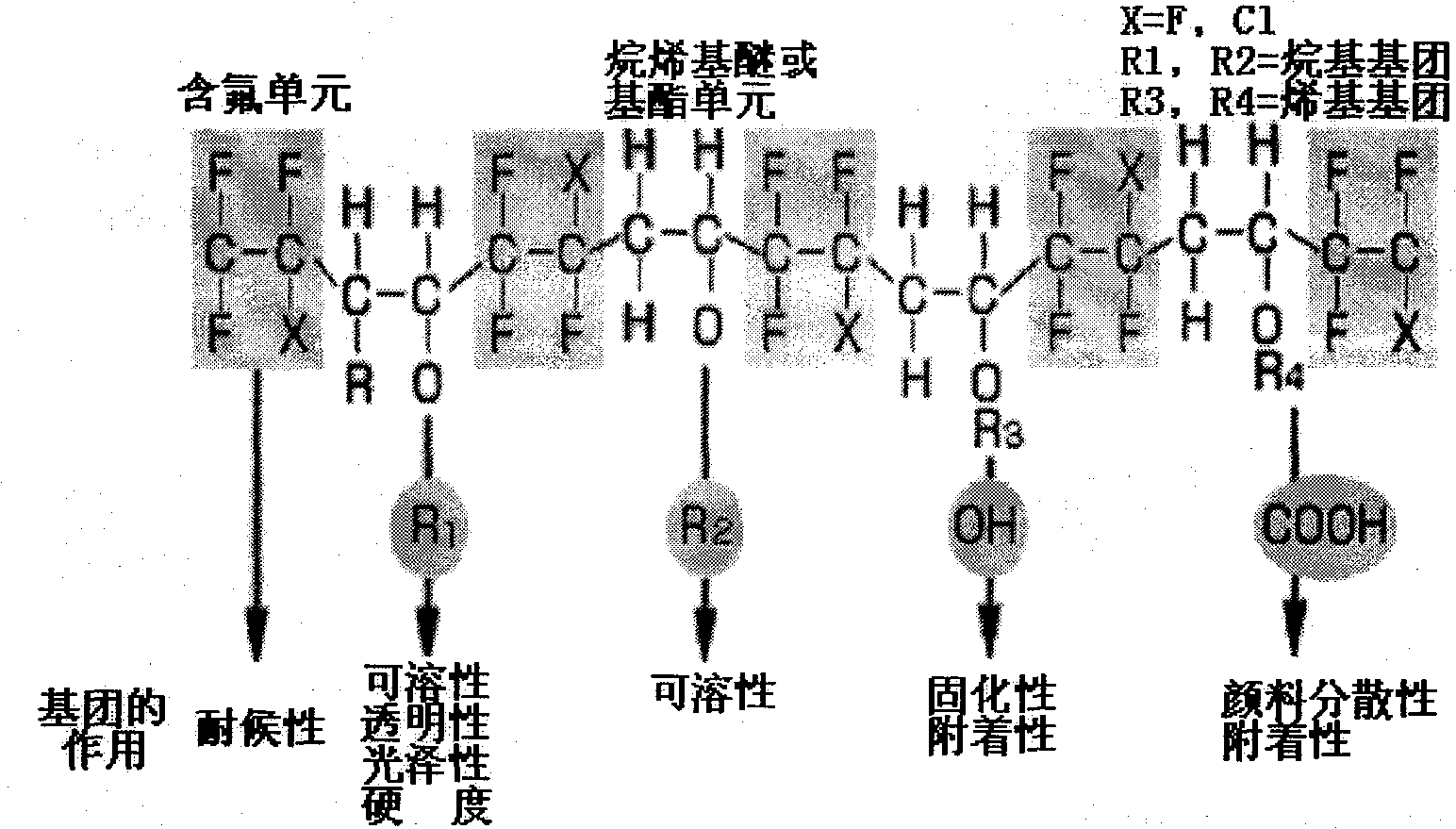

A fluorocarbon coating, high weather resistance technology, applied in the direction of coating, etc., can solve the problems of high VOC content, misunderstanding, low fluorine content of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

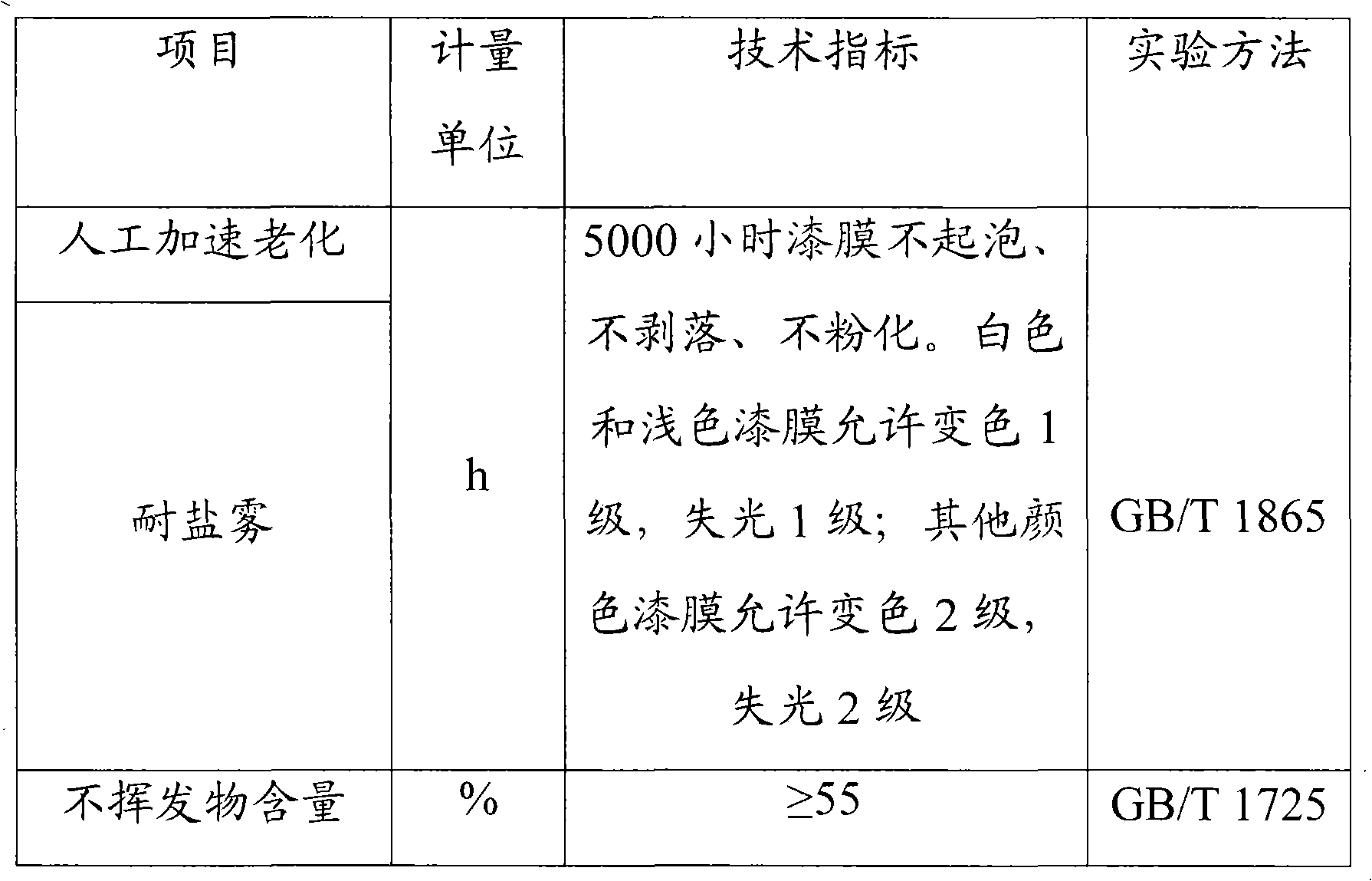

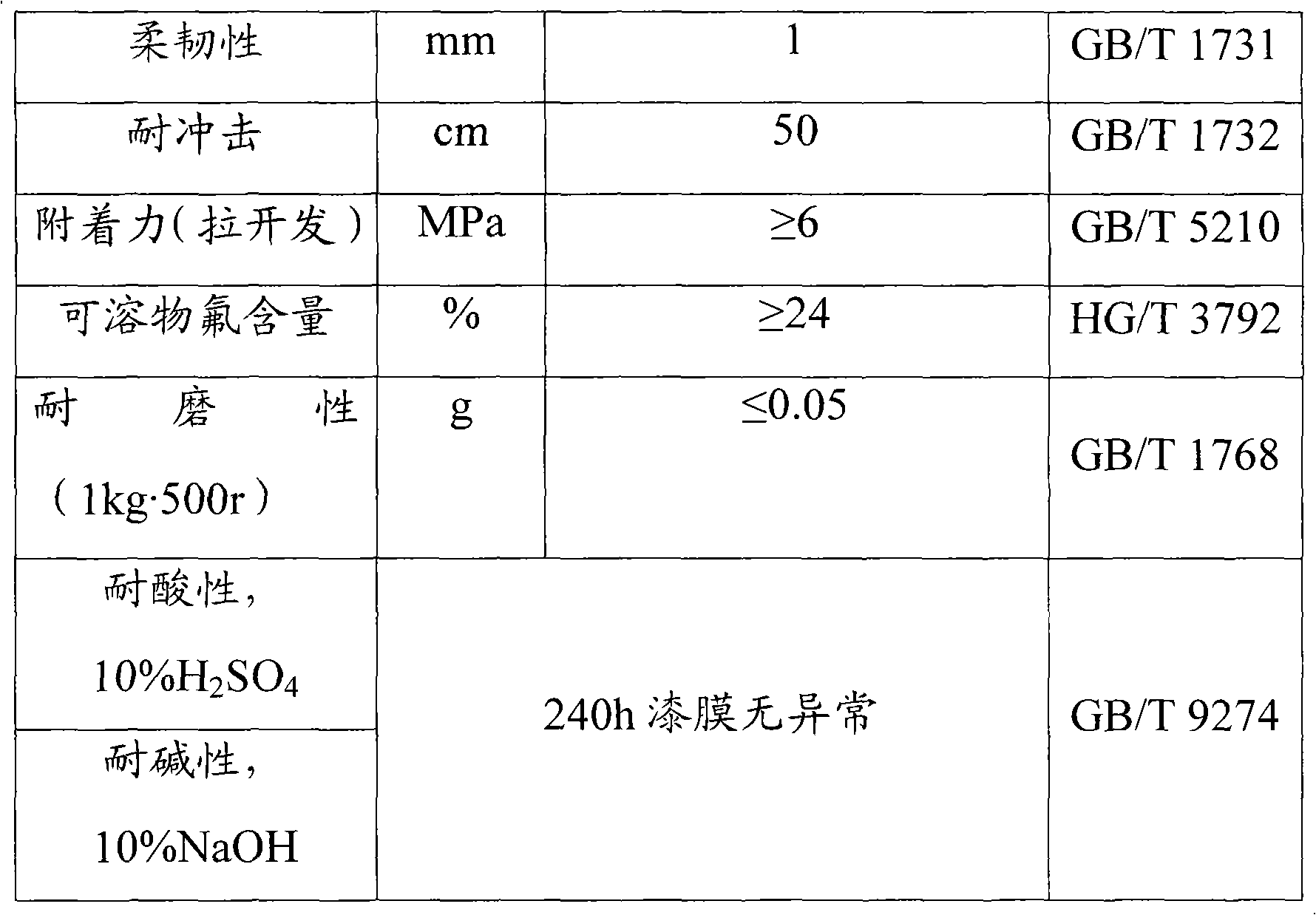

Examples

Embodiment 1

[0066] Preparation of component A: 3 grams of anti-aging agent (wherein ultraviolet absorber phenyl salicylate: quencher nickel di-n-butyldithiocarbamate: free radical scavenger bis(1,2,2,6, The molar ratio of 6-pentamethyl-4-piperidinyl) sebacate is 1.0:0.6:0.6), 2.5 grams of self-cleaning aid fluorine-modified siloxane, 2 grams of modified polysiloxane type fluid Leveling agent, 1.5 grams of wetting and dispersing agent, added to 60 grams of fluorocarbon resin, 10 grams of mixed solvent made of propylene glycol methyl ether acetate and butyl acetate according to 1:2 and stirred for more than 0.5 hours, so that the two were fully mixed Evenly, add 30 grams of titanium dioxide, 3 grams of 1000-mesh mica to the above solution, and stir for more than 0.5 hours until uniform. Grind the mixed slurry to a fineness below 25 μm to obtain a white slurry. Add 40 grams of resin and 5 grams of mixed solvent to the above white paste to prepare component A of the white paint.

[0067] Pr...

Embodiment 2

[0070] Preparation of component A: 3 grams of anti-aging agent (wherein ultraviolet absorber benzophenone: quencher thiobisphenol nickel: free radical scavenger 4-piperidinyl) the molar ratio of sebacate is 1.0: 0.9: 0.8), 2.5 grams of self-cleaning aids, 2 grams of modified polysiloxane type leveling agents, 1.5 grams of wetting and dispersing agents, added to 60 grams of fluorocarbon resin, 10 grams of a mixed solvent made of propylene glycol methyl ether acetate and butyl acetate at a ratio of 1:2 were stirred for more than 0.5 hours to fully mix the two, and 28 grams of medium chrome yellow and 3 grams of talc Add the powder into the above resin solution and stir for more than 0.5 hours until uniform. Grind the mixed slurry to a fineness below 25 μm to obtain medium chrome yellow slurry. Add 40 grams of resin and 5 grams of mixed solvent to the above color paste to prepare component A of medium chrome yellow paint.

[0071] Preparation of component B: Dissolve 65g of HDI...

Embodiment 3

[0074] Preparation of component A: 3 grams of anti-aging agent (wherein UV absorber benzotriazole ester: quencher phosphonic acid monoester nickel: free radical scavenger bis(1,2,2,6,6-pentamethyl The molar ratio of -4-piperidinyl) sebacate is 1.5: 0.8: 0.6), 2.5 grams of self-cleaning additives, 2 grams of modified polysiloxane type leveling agents, 1.5 grams of wetting and dispersing agents, adding Stir in 60 grams of fluorocarbon resin, 10 grams of mixed solvent made of propylene glycol methyl ether acetate and butyl acetate at 1:2 for more than 0.5 hours, so that the two are fully mixed evenly, and 28 grams of chrome yellow, 3 grams Add talcum powder into the above resin solution and stir for more than 0.5 hours until uniform. Grind the mixed slurry to a fineness below 25 μm to obtain medium chrome yellow slurry. Add 40 grams of resin and 5 grams of mixed solvent to the above color paste to prepare component A of medium chrome yellow paint.

[0075] Preparation of compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com