Agate marble heat-insulation building decorative component of building and installation method thereof

A technology of imitating marble and building decoration, applied in the field of building decoration components, can solve the problems of inconvenient transportation and cutting, high material consumption, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

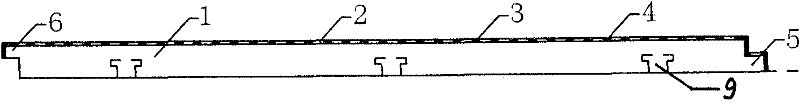

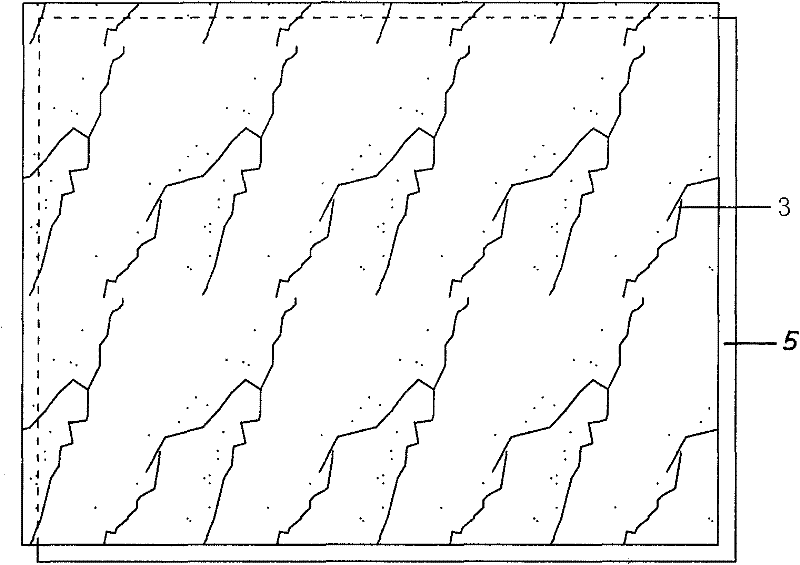

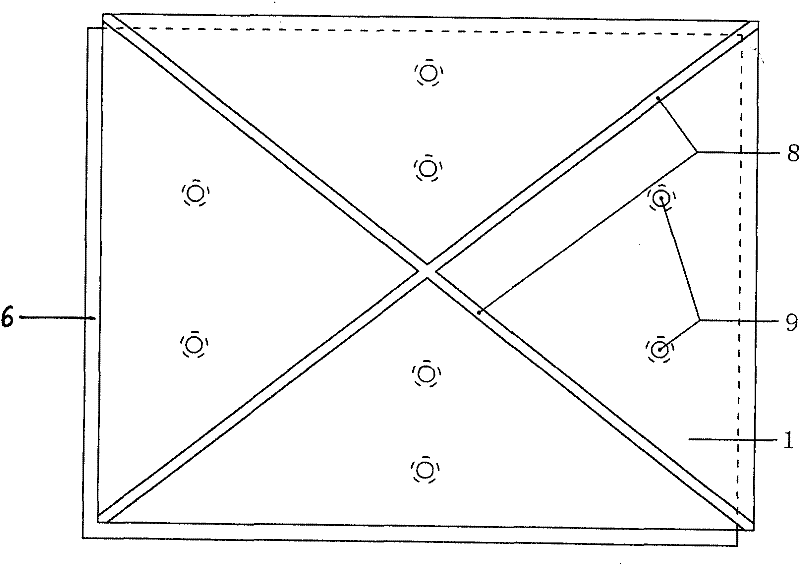

[0014] Such as Figure 1 to Figure 4 Shown, the present invention imitates marble thermal insulation building decoration member, comprises the foam inner layer 1 (being high strength, high density flame-retardant polystyrene foam material) that is contained in building outer wall body surface, in said foam The outer surface of the inner layer 1 is successively provided with a mortar coating 2 (the material is organic polymer mortar, which has a hydrophobic function) and a stone coating 3 (the material is inorganic stone, which has a hydrophobic function), and the mortar coating Layer 2 is provided with mesh cloth layer 4 (the material is alkali-resistant glass fiber mesh cloth, which acts as a reinforcement and has crack resistance). There is no mortar coating 2 and stone coating 3 on the installation surface of the foam inner layer 1 .

[0015] The two sides of the foam inner layer 1 respectively have stepped bosses 5 and recesses 6 (the bosses and recesses between the sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com