DC toughened glass insulator

A glass insulator and section steel technology, applied in inorganic insulators, insulators, suspension/strain insulators, etc., can solve the problem that the disc-shaped suspension tempered glass fiber reinforced plastic insulator cannot be directly applied, the mechanical strength of steel feet and tempered glass insulators is reduced, and the tempered glass insulator is aging. and other problems, to achieve the effect of reducing the amount of migrated charge, increasing the air distance and flashover voltage, and reducing the aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

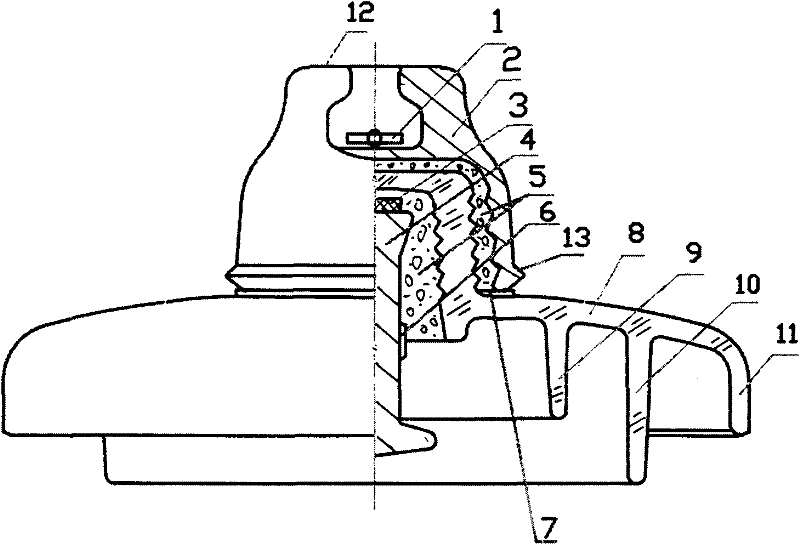

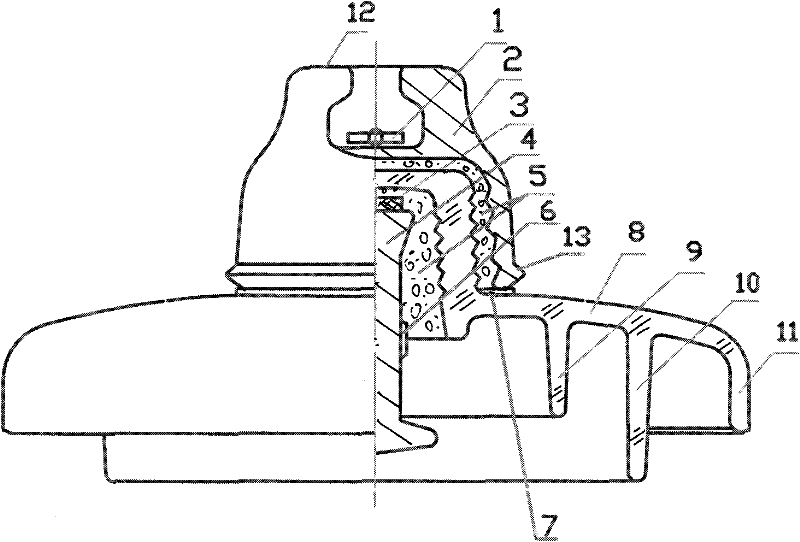

[0014] Example 1, in figure 1 Wherein, the DC-type tempered glass insulator includes an iron cap 2, a glass piece 8, a steel foot 4, and a glue 5. The iron cap 2 has a zinc ring 13 at the lower end, and the iron cap is supported on the glass piece by a lower gasket 7. , The steel foot 4 passes through the inner hole of the glass piece 8 and is connected to the glass piece through the locking pin 1 and the upper gasket 3. The glass piece has a maximum disc diameter of 320 mm and a weight of 11 kg. A glue 5 is filled in between, a zinc sleeve 6 is set on the steel foot, and a glue is filled between the steel foot and the glass piece, the glue is ordinary Portland cement, and the glass piece has a circular ring shape. The outer umbrella skirt 11, the circular first inner umbrella skirt 10 and the circular second inner umbrella skirt 9, the heights of the outer umbrella skirt, the first inner umbrella skirt and the second inner umbrella skirt are respectively The distance from the...

Embodiment 2

[0015] Example 2, reference figure 1 The glass piece 8 has a maximum disc diameter of 400 mm and a weight of 15 kg. The weight percentages of the main chemical components of the glass piece are: sodium oxide 18.8%, potassium oxide 16.1%, magnesium oxide 7.1%, barium oxide 2.48%, aluminum oxide 2.39%, the rest is silica. The other structure is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com