Enamel non-stick fry pan

A non-stick pan and ceramic technology, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problems of non-stick pans losing non-stick function, harmful to human body, toxic products, etc., and achieve good chemical stability And cold and hot rapid change performance, safe and long-term use, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

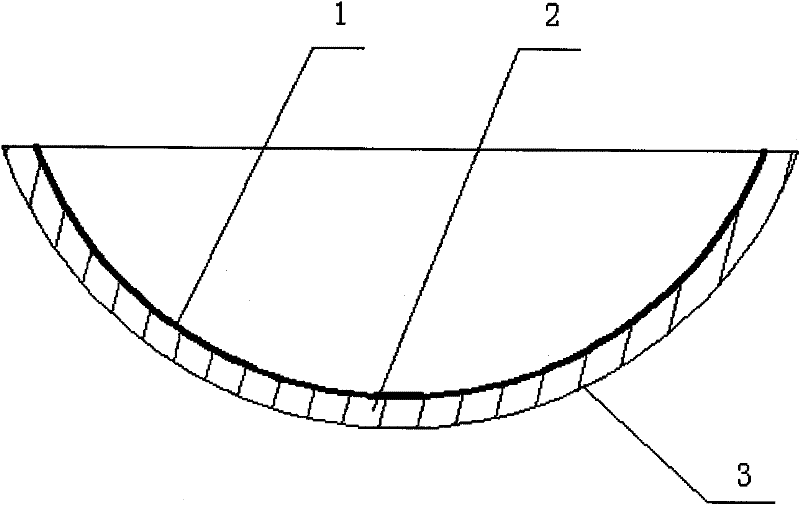

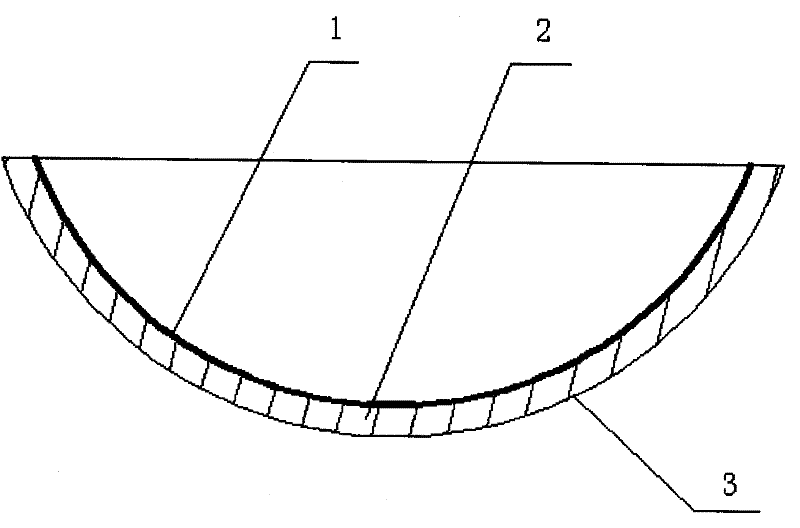

[0014] Embodiment 1: As shown in the accompanying drawings, the enamelled pottery non-stick pan of the present invention includes a pot body 2, and a pottery surface glaze layer 1 is enamelled on the inner surface of the pot body 2. The bottom glaze 3 is enamelled on the surface; the ceramic surface glaze layer 1 is provided with dense capillary pores; the diameter of the capillary pores is 0.1-120.0 microns.

[0015] The ceramic surface glaze in the present invention comprises the following components, and the weight ratios of each component are respectively: 20% of granular barren material, 79.2% of pottery slurry, and 0.8% of pore-forming agent; wherein the material of granular barren material is quartz Any one of texture, corundum texture, mullite texture, and clay texture, and the particle size of the granular barren material is ≤ 100 mesh; the pore-forming agent is sodium carbonate. The ceramic slurry is a kind of mixed slurry with low sintering temperature and has high-...

Embodiment 2

[0016] Embodiment 2: The enamelled pottery non-stick pan of the present invention comprises a pot body 2, and a pottery surface glaze layer 1 is enamelled on the inner surface of the pot body 2, and the pottery surface glaze layer 1 is provided with dense capillary pores ; Wherein the pore diameter of the capillary is 0.1-120.0 microns.

[0017] In the present invention, the ceramic surface glaze comprises the following components, and the weight ratios of each component are respectively: 60% of granular barren material, 39.8% of pottery slurry, and 0.2% of pore-forming agent; wherein the material of granular barren material is quartz Quality, corundum quality, granular barren material particle size ≤ 100 mesh; ceramic slurry is a kind of mixed slurry with low sintering temperature, which has high temperature binder properties; the pore forming agent is calcium carbonate.

Embodiment 3

[0018] Embodiment 3: The enamelled pottery non-stick pan of the present invention comprises a pot body 2, a pottery surface glaze layer 1 is enamelled on the inner surface of the pot body 2, and a bottom is enamelled on the outer surface of the pot body 2 Glaze 3; ceramic surface glaze layer 1 is provided with dense capillary pores; wherein the diameter of the capillary pores is 0.1-120.0 microns.

[0019] In the present invention, the ceramic surface glaze layer comprises the following components, and the weight ratio of each component is respectively: 30% of granular barren material, 69.5% of pottery slurry, and 0.5% of pore-forming agent; wherein the material of granular barren material is Quartz, corundum, mullite, particle size of granular barren materials ≤ 100 mesh; ceramic slurry is a kind of mixed slurry with low sintering temperature, which has high temperature binder characteristics; pore forming agent is carbon powder .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com