Clean energy utilization method for municipal solid wastes

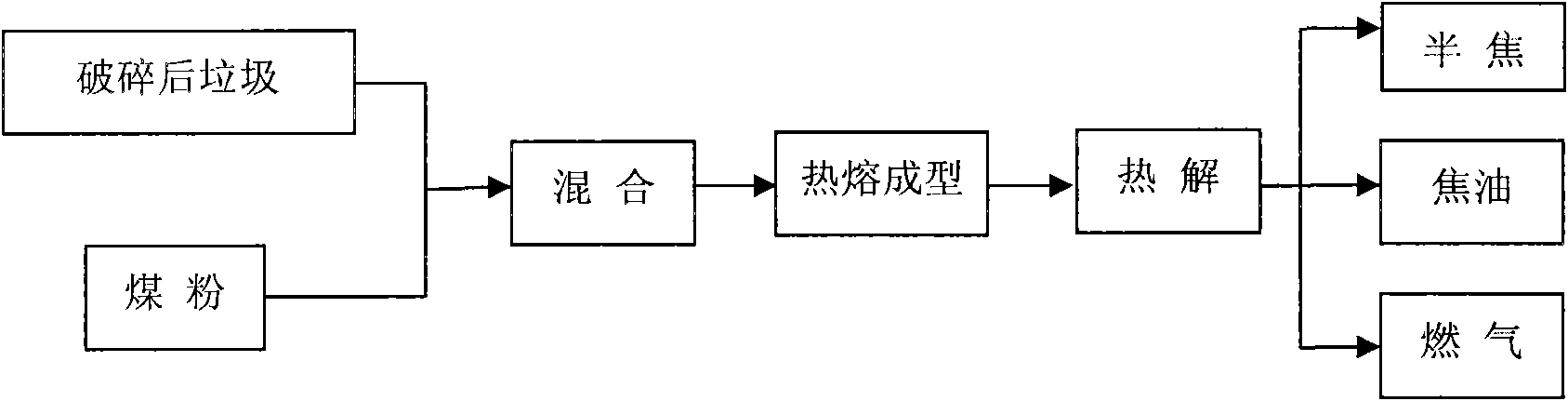

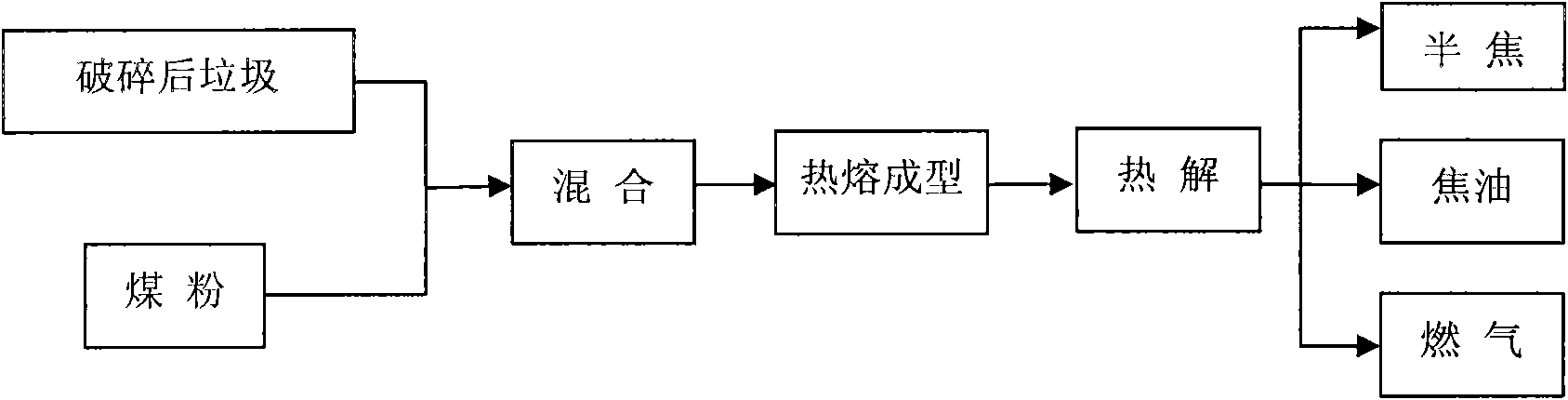

A technology of municipal solid waste and clean energy, which is applied in the field of clean energy utilization of municipal solid waste, and can solve problems such as difficulty in realizing resource utilization and energy utilization value, difficulty in realizing economic benefits of process technology, and poor quality of coke produced by pyrolysis and carbonization , to achieve high value-added utilization, avoid generation and diffusion, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take municipal solid waste on a 15mm sieve, and recover magnetic substances through magnetic separation. Crushed to 20mm, and dried with a drum, the moisture content of the dried garbage was detected to be 8.3%. Coal powder is selected from Shenhua coal with a moisture content of 13.4%. According to the total amount of 2kg on a dry basis, the proportion of municipal solid waste added is 70% for batching, mix evenly, heat and compact the mixed material to a density of 400kg / m 3 Left and right, into the 2kg small coke oven experimental device. Keep the temperature in the center of the furnace at 100°C for 5 minutes, then continue to increase the temperature, and turn off the heating system when the temperature in the center of the furnace reaches 960°C for 2 minutes. The product yield is 68.0% of coke, 13.6% of tar, and 18.4% of gas, of which the calorific value of semi-coke is 12420KJ / Kg, and the calorific value of gas is 13349KJ / m 3 .

Embodiment 2

[0033] Take municipal solid waste on a 15mm sieve, and recover magnetic substances through magnetic separation. Crushed to 20mm, and dried with a drum, the moisture content of the dried garbage was detected to be 8.3%. Coal powder is selected from Shenhua coal with a moisture content of 13.4%. According to the total amount of 2kg on a dry basis, the proportion of municipal solid waste added is 50% for batching, mix evenly, heat and compact the mixed material to a density of 400kg / m 3 Left and right, into the 2kg small coke oven experimental device. Keep the temperature in the center of the furnace at 100°C for 5 minutes, then continue to increase the temperature, and turn off the heating system when the temperature in the center of the furnace reaches 960°C for 2 minutes. The product yield is 70.0% of coke, 10.2% of tar, and 19.8% of gas, of which the calorific value of semi-coke is 16240KJ / Kg, and the calorific value of gas is 11698KJ / m 3 .

Embodiment 3

[0035] Take municipal solid waste on a 15mm sieve, and recover magnetic substances through magnetic separation. Crushed to 20mm, and dried with a drum, the moisture content of the dried garbage was detected to be 8.3%. Coal powder is selected from Shenhua coal with a moisture content of 13.4%. According to the total amount of 2kg on a dry basis, the proportion of municipal solid waste added is 30% for batching, mix evenly, heat and compact the mixed material to a density of 400kg / m 3 Left and right, into the 2kg small coke oven experimental device. Keep the temperature in the center of the furnace at 100°C for 5 minutes, then continue to increase the temperature, and turn off the heating system when the temperature in the center of the furnace reaches 960°C for 2 minutes. The product yield is 68.8% of coke, 4.4% of tar, and 26.8% of gas, of which the calorific value of semi-coke is 22720KJ / Kg, and the calorific value of gas is 13231KJ / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com