Method for preparing high-quality ZnO monocrystal film on sapphire substrate

A sapphire substrate and single crystal thin film technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as small viscosity coefficient, short migration length, easy island growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

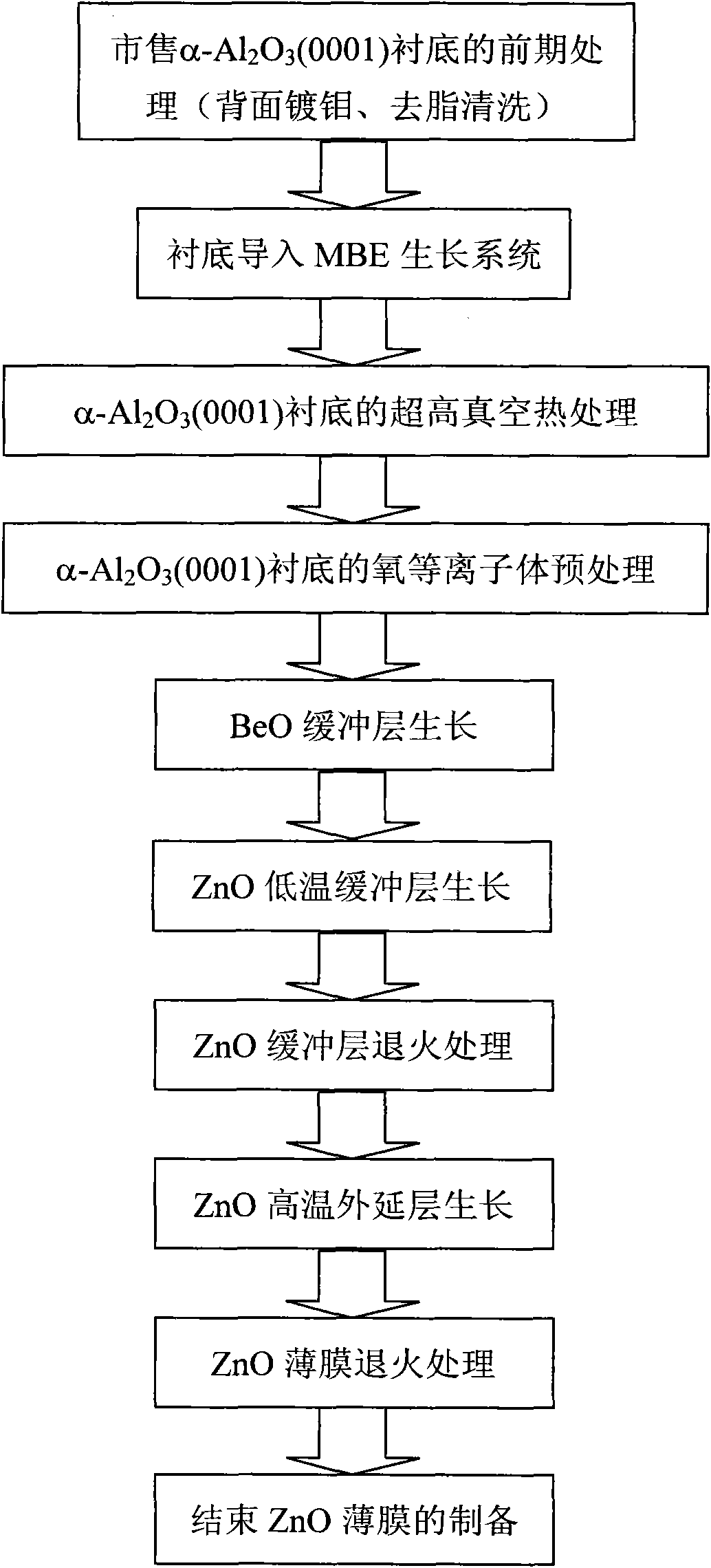

[0039] Such as figure 1 Shown process flow diagram of the present invention, the concrete steps of preparing high-quality ZnO single crystal thin film on sapphire (0001) substrate are as follows:

[0040] 1. Use known methods to carry out molybdenum plating on the back of the commercially available sapphire (0001) substrate, and perform chemical degreasing and cleaning, and then import the substrate into the MBE system;

[0041] 2. First in ultra-high vacuum (not less than 1×10 -8 mbar) conditions, the substrate is heated to 700°C for 30 minutes of heat treatment, and then the substrate surface is treated with active oxygen plasma for 30 minutes at 100°C, the radio frequency power is 300W, and the oxygen flow rate is 2.0sccm;

[0042] 3. The epitaxial growth of the BeO buffer layer is carried out at a substrate temperature of 500°C, and the equivalent vapor pressure of the Be beam is 5x10 -4 Around Pa, a thin layer of BeO with a thickness of about 2nm is obtained;

[0043] ...

Embodiment 2

[0050] Such as figure 1 Shown process flow diagram of the present invention, the concrete steps of preparing high-quality ZnO single crystal thin film on sapphire (0001) substrate are as follows:

[0051] 1. Use known methods to carry out molybdenum plating on the back of the commercially available sapphire (0001) substrate, and perform chemical degreasing and cleaning, and then import the substrate into the MBE system;

[0052] 2. First, in ultra-high vacuum (not less than 1×10 -8 mbar) conditions, the substrate is heated to 800°C for 20 minutes of heat treatment, and then the surface of the substrate is treated with active oxygen plasma at 300°C for 20 minutes, the radio frequency power is 300W, and the oxygen flow rate is 2.0sccm;

[0053] 3. The epitaxial growth of the BeO buffer layer is carried out under the condition of the substrate temperature of 1000°C, and the equivalent vapor pressure of the Be beam is 5x10 -4 Around Pa, a thin layer of BeO with a thickness of ab...

Embodiment 3

[0060] Such as figure 1 Shown process flow diagram of the present invention, the concrete steps of preparing high-quality ZnO single crystal thin film on sapphire (0001) substrate are as follows:

[0061] 1. Use known methods to carry out molybdenum plating on the back of the commercially available sapphire (0001) substrate, and perform chemical degreasing and cleaning, and then import the substrate into the MBE system;

[0062] 2. First in ultra-high vacuum (not less than 1×10 -8 mbar), the substrate is heated to 900°C for 10 minutes of heat treatment, and then the surface of the substrate is treated with active oxygen plasma at 500°C for 10 minutes, the radio frequency power is 300W, and the oxygen flow rate is 2.0sccm;

[0063] 3. The epitaxial growth of the BeO buffer layer is carried out at a substrate temperature of 1500°C, and the equivalent vapor pressure of the Be beam is 5x10 -4 pa, obtain a thin layer of BeO with a thickness of about 30nm;

[0064] 4. Deposit a Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com