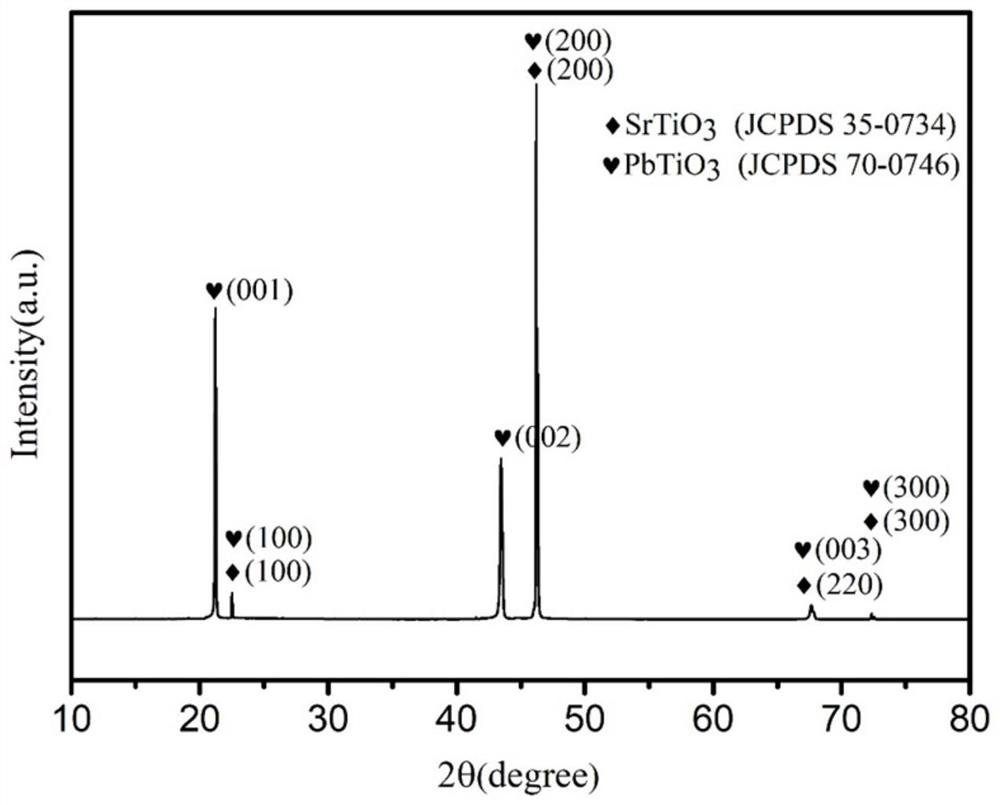

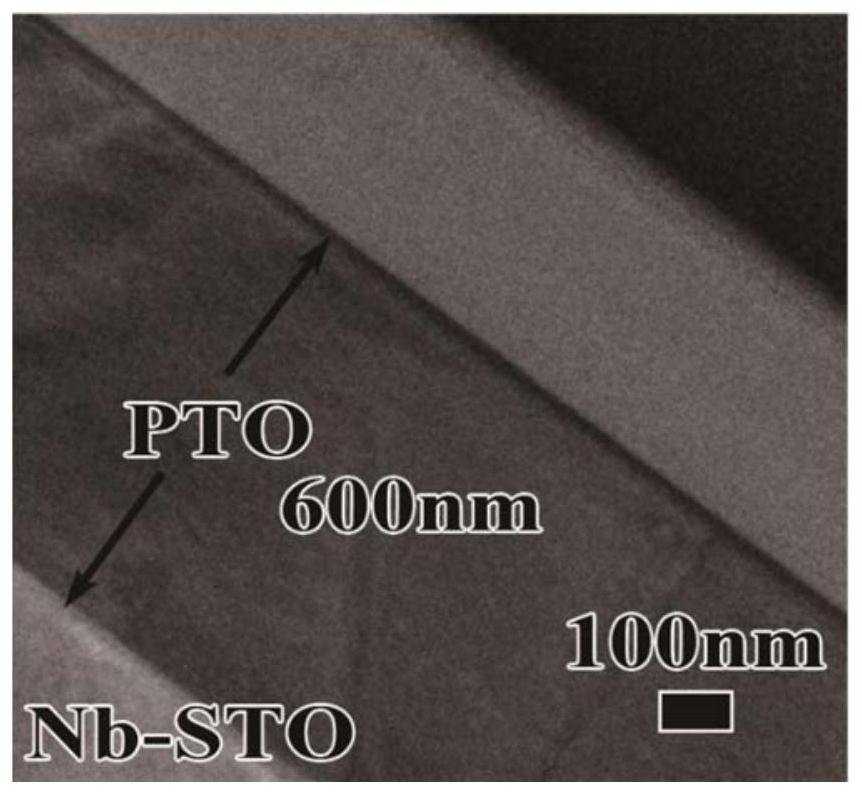

A kind of preparation method of lead titanate film based on strontium titanate doped niobate

A technology doped with strontium niobate titanate and lead titanate, which is applied in the field of preparation of lead titanate thin films, can solve the problems that pure lead titanate thin films cannot be put into practical application, high grain boundary energy, etc., and achieve low cost, easy control, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]1) Weigh an appropriate amount of potassium hydroxide and place it in the inner pot of the polytetrafluoroethylene reactor, add 20 mL of deionized water to dissolve, stir thoroughly, and obtain a potassium hydroxide aqueous solution with a molar concentration of 4 mol / L;

[0026]2) Under stirring, add 1.708 g of tetra-n-butyl titanate to the potassium hydroxide aqueous solution prepared in step 1), and stir for 10 minutes;

[0027]3) Weigh an appropriate amount of lead nitrate, dissolve it in deionized water, and stir thoroughly to obtain an aqueous solution of lead nitrate; the molar ratio of lead to titanium is 1.25;

[0028]4) The lead nitrate aqueous solution prepared in step 3) is added to 2), and the volume of the reaction material in the reactor tank is adjusted with deionized water to reach 80% of the reactor tank volume (the volume of the reactor tank is 45ml ), stir for at least 2h to obtain a precursor solution, the volume base of the molar concentration is the total volume ...

Embodiment 2

[0032]1) Weigh an appropriate amount of potassium hydroxide and place it in the inner pot of the polytetrafluoroethylene reactor, add 20 mL of deionized water to dissolve, stir thoroughly, and obtain a potassium hydroxide aqueous solution with a molar concentration of 4 mol / L;

[0033]2) Under stirring, add 0.854 g of tetra-n-butyl titanate to the potassium hydroxide aqueous solution prepared in step 1), and stir for 10 minutes;

[0034]3) Weigh an appropriate amount of lead nitrate, dissolve it in deionized water, and stir thoroughly to obtain an aqueous solution of lead nitrate. The molar ratio of lead to titanium is 1.25;

[0035]4) Add the lead nitrate aqueous solution prepared in step 3) to 2), adjust the volume of the reaction material in the reactor tank with deionized water to reach 80% of the reactor tank volume, and stir for at least 2 hours to obtain a precursor solution , The volume base of the molar concentration is the total volume of the precursor solution;

[0036]5) Wash the ni...

Embodiment 3

[0039]1) Weigh an appropriate amount of potassium hydroxide and place it in the inner pot of the polytetrafluoroethylene reactor, add 20mL of deionized water to dissolve, stir well, and obtain a potassium hydroxide aqueous solution with a molar concentration of 4.7mol / L;

[0040]2) Under stirring, add 1.708 g of tetra-n-butyl titanate to the potassium hydroxide aqueous solution prepared in step 1), and stir for 10 minutes;

[0041]3) Weigh an appropriate amount of lead nitrate, dissolve it in deionized water, and stir thoroughly to obtain an aqueous solution of lead nitrate. The molar ratio of lead to titanium is 1.25;

[0042]4) Add the lead nitrate aqueous solution prepared in step 3) to 2), adjust the volume of the reaction material in the reactor tank with deionized water to reach 80% of the reactor tank volume, and stir for at least 2 hours to obtain a precursor solution , The volume base of the molar concentration is the total volume of the precursor solution;

[0043]5) Wash the niobium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com