Method for preparing nitrogenous porous carbon material for electrode material of super-capacitor

A technology of supercapacitors and electrode materials, applied in capacitors, electrolytic capacitors, circuits, etc., to achieve the effects of low cost, good rate performance, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Supercapacitor electrode material nitrogen-containing porous carbon I.

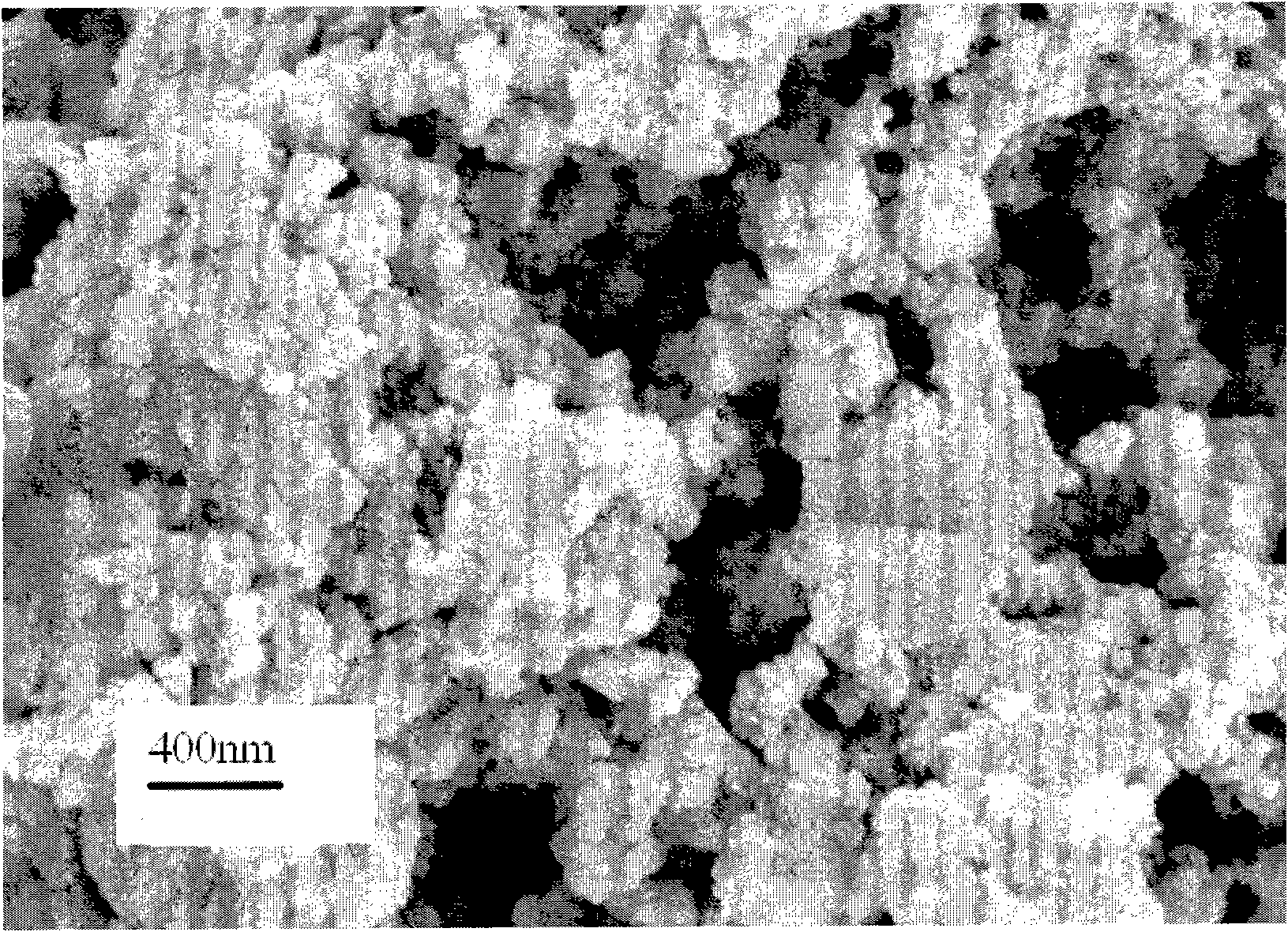

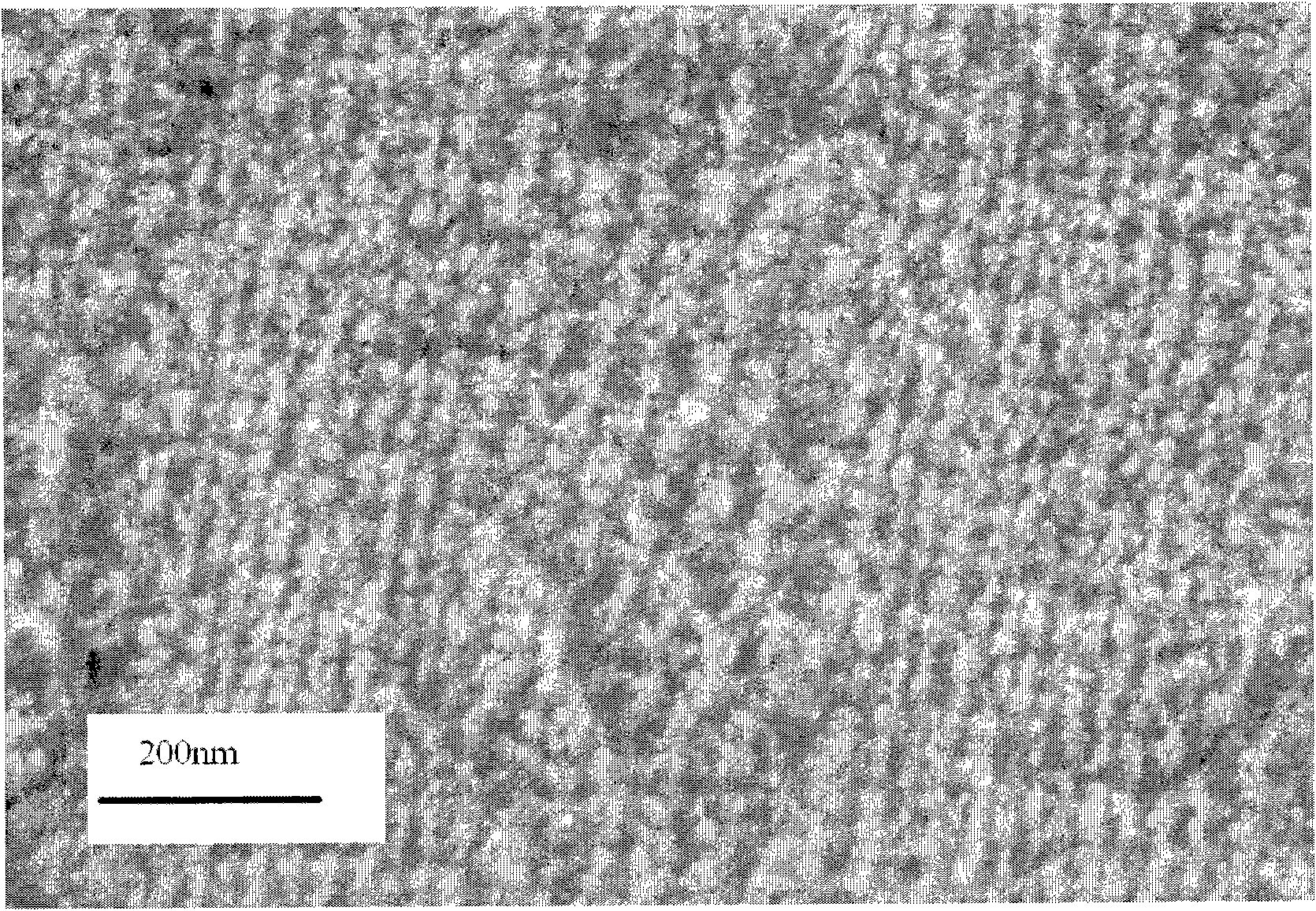

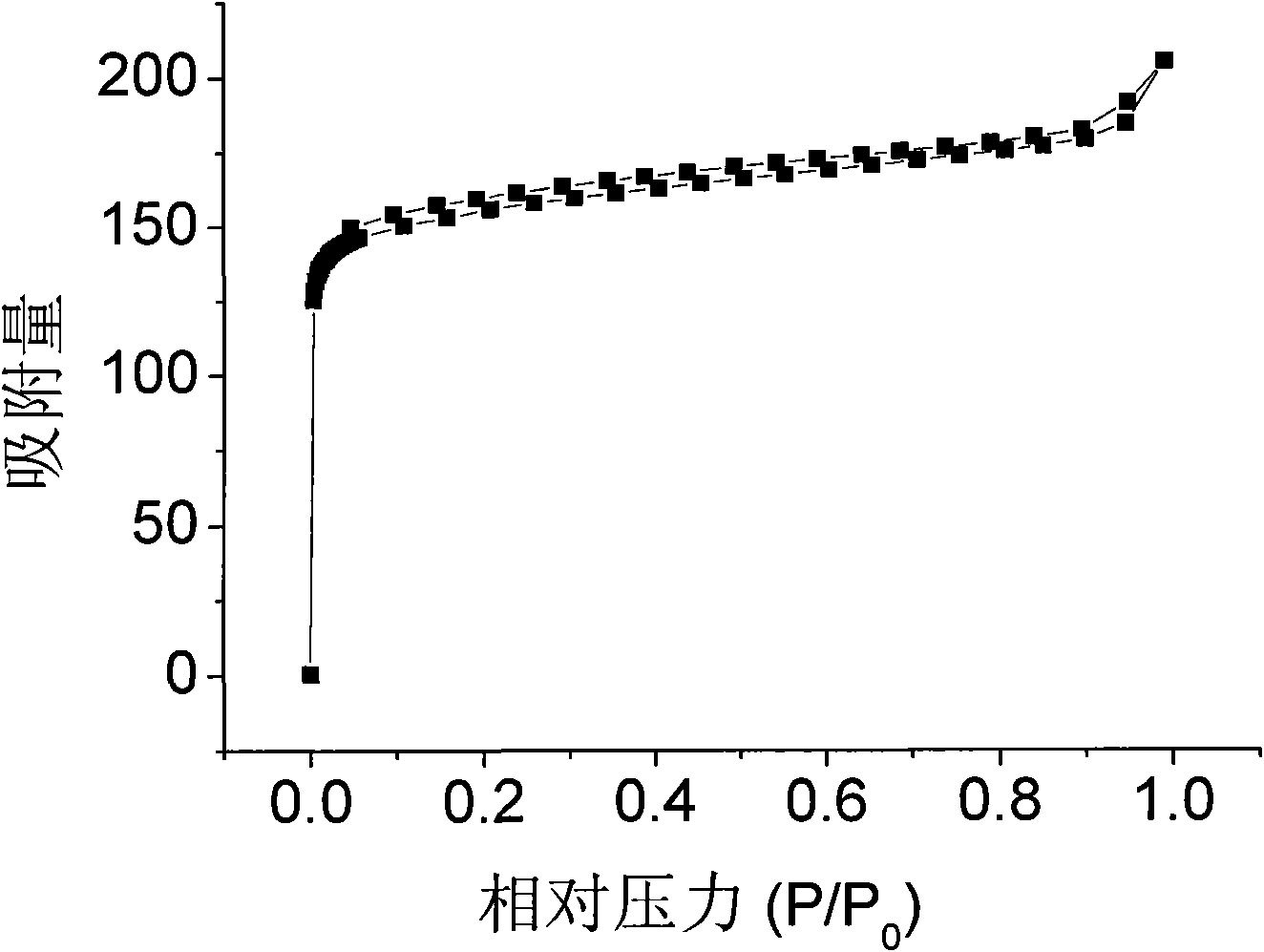

[0019] Glucosamine hydrochloride and deionized water were uniformly mixed at a ratio of 1:9, and hydrothermally treated at 180° C. for 12 hours in a polytetrafluoroethylene autoclave to obtain a hydrothermal nitrogen-containing porous carbon precursor. figure 1 It is a typical scanning electron micrograph of a porous carbon precursor synthesized by hydrothermal method. The nitrogen content of the precursor is 7.1%, the carbon content is 67.22%, and the specific surface area is 18m 2 / g; then the precursor and potassium hydroxide were mixed in a mass ratio of 1:2, under the protection of nitrogen, kept at 600° C. for 4 hours, and the obtained product was washed with water to neutrality to obtain nitrogen-containing porous carbon I. Typical scanning electron micrographs of nitrogen-containing porous carbons are as follows: figure 2 . The nitrogen content of the nitrogen-containing po...

Embodiment 2

[0020] Example 2: Supercapacitor electrode material Nitrogen-containing porous carbon II.

[0021] Glucosamine hydrochloride and deionized water are uniformly mixed at 1:9, and in a polytetrafluoroethylene autoclave, 180° C. of hydrothermal treatment for 12 hours obtains a hydrothermal nitrogen-containing porous carbon precursor; then the precursor is mixed with Potassium hydroxide was mixed at a mass ratio of 1:8, and kept at 600° C. for 4 hours under the protection of nitrogen, and the obtained product was washed with water to neutrality to obtain nitrogen-containing porous carbon II. The nitrogen content of the nitrogen-containing porous carbon is 1.3%, and the carbon content is 18.22%. Its specific surface area is 330m 2 / g. The electrode material has a maximum specific capacitance of 86F / g in 1M sulfuric acid electrolyte. The specific capacitance of the electrode material in 6M potassium hydroxide can be as high as 61F / g. The highest specific capacitance of the electr...

Embodiment 3

[0022] Example 3: Supercapacitor Electrode Material Nitrogen-Containing Porous Carbon III.

[0023] Glucosamine hydrochloride and deionized water are uniformly mixed at 1:9, and in a polytetrafluoroethylene autoclave, 180° C. of hydrothermal treatment for 12 hours obtains a hydrothermal nitrogen-containing porous carbon precursor; then the precursor is mixed with Potassium hydroxide was mixed in a mass ratio of 1:4, under the protection of nitrogen, kept at 600°C for 4 hours, and the obtained product was washed with water until neutral to obtain nitrogen-containing porous carbon III. The nitrogen content of the nitrogen-containing porous carbon is 2.8%, and the carbon content is 40.8%. Its specific surface area is 600m 2 / g. The electrode material has a maximum specific capacitance of 269F / g in 1M sulfuric acid electrolyte. The specific capacitance of the electrode material in 6M potassium hydroxide can be as high as 175F / g. The highest specific capacitance of the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com