Novel oxy-fuel combustion glass melting furnace

An all-oxygen combustion, glass melting furnace technology, applied in glass production, glass furnace equipment, glass manufacturing equipment and other directions, can solve the problems of increasing output, unable to increase the temperature of the melting furnace indefinitely, to increase output, be conducive to clarification and uniformity Optimal, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

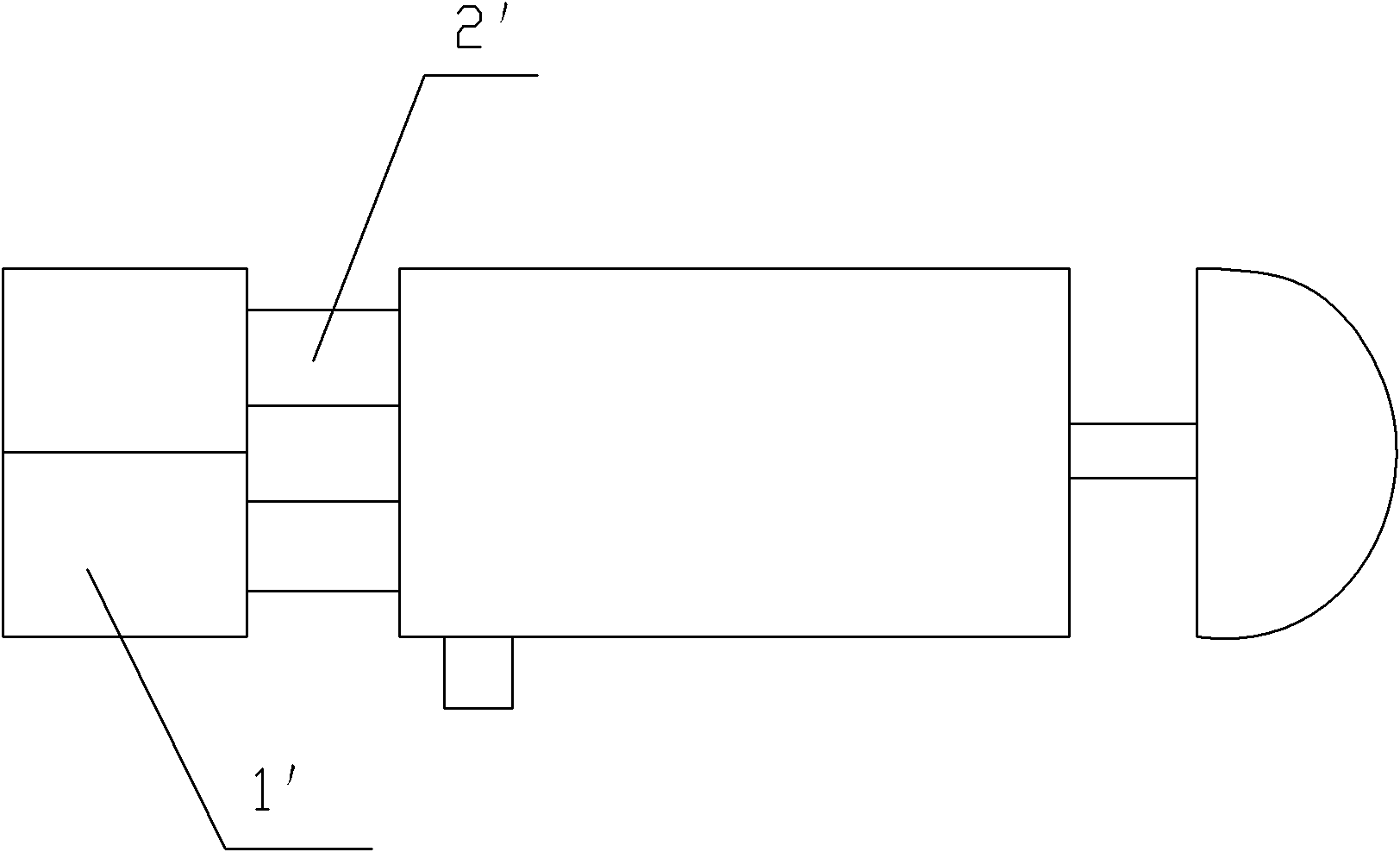

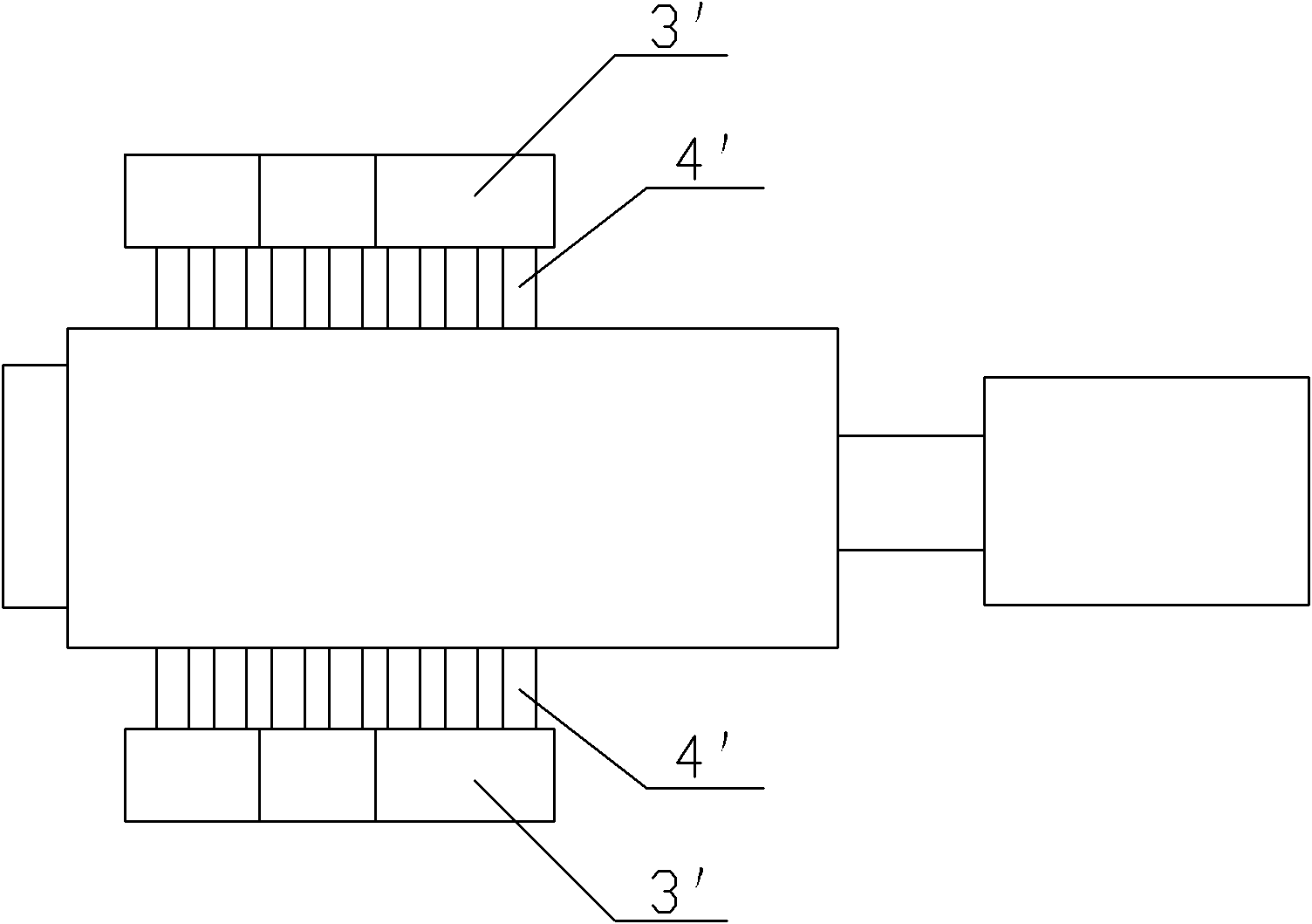

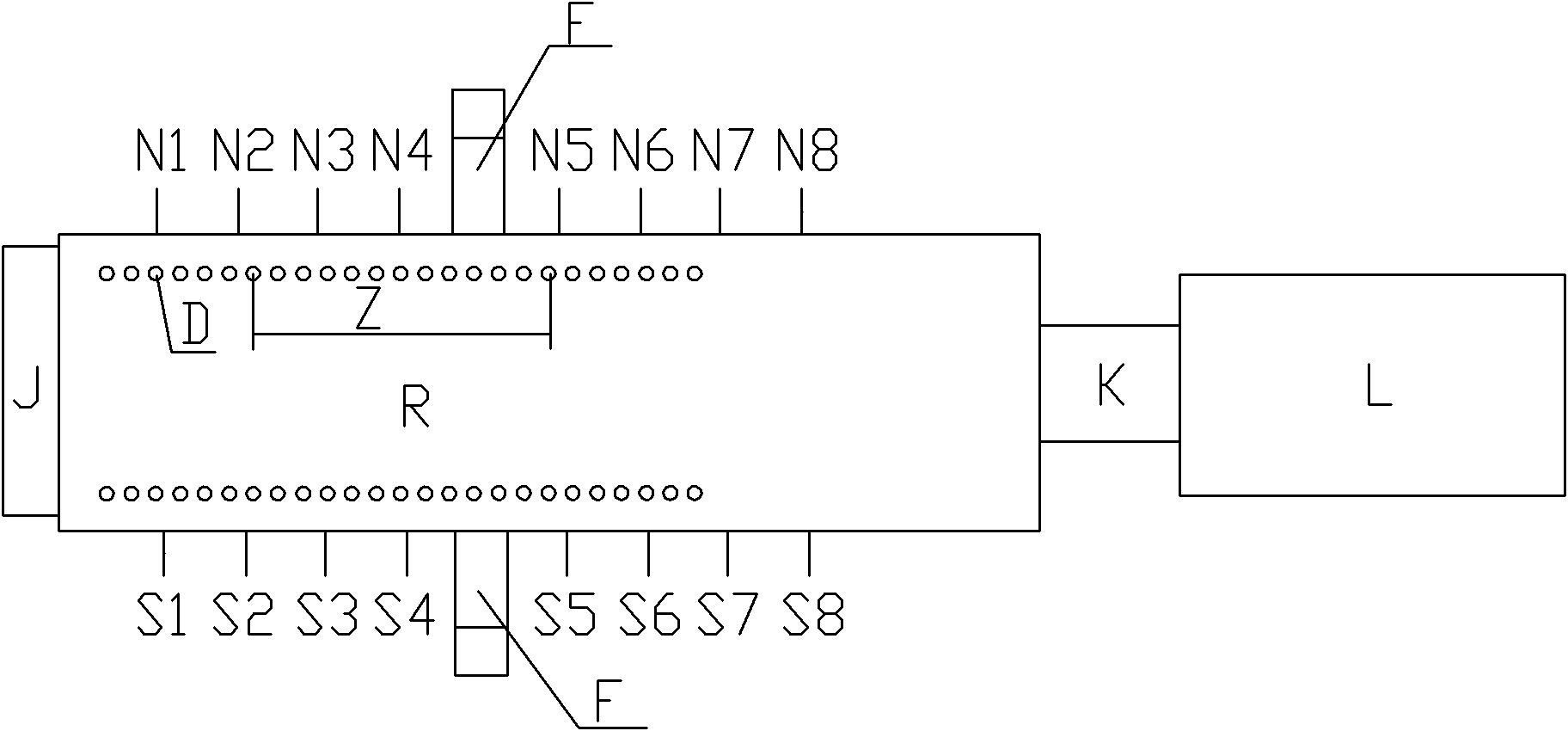

[0023] Example 1, please refer to image 3 , Figure 4 As shown, a novel oxy-fuel combustion glass melting furnace of the present invention includes a feeding port J, a melting part R, a neck or a flow hole K and a cooling part L; a feeding port J, a melting part R, a neck Or the liquid flow hole K and the cooling part L are connected in sequence; the melting part R includes a melting pool and parapets X arranged on both sides of the melting pool; the melting part R is provided with a hot spot along the middle section of the feeding direction of the molten glass ; There is also a flue F and 8 oxygen burners on the parapet walls on both sides of the melting part R, of which one side is the oxygen burner S1, the oxygen burner S2, the oxygen burner S3, the oxygen burner Burning gun S4, full oxygen burning gun S5, full oxygen burning gun S6, full oxygen burning gun S7, full oxygen burning gun S8; the other side is full oxygen burning gun N1, full oxygen burning gun N2, full oxyge...

Embodiment 2

[0032] Embodiment 2, a new type of all-oxygen glass melting furnace of the present invention, please refer to Figure 5 As shown, the difference from Example 1 is that the arrangement of the pill-shaped molybdenum electrodes D' in the third area near the neck or the liquid hole K side is along the direction perpendicular to the flow of the molten glass. Give directions in two rows. Apparently, the arrangement of the pill-shaped molybdenum electrodes D' in the third area on the side of the neck or the flow hole K is beneficial to the pill-shaped molybdenum electrodes D' when the temperature of the molten glass rises and the convection strengthens, which is equivalent to that in the molten glass. The horizontal direction of the kiln acts as a barrier, which can improve the horizontal and vertical convection of the molten glass, prolong the residence time of the molten glass in the melting furnace, and reduce the amount of molten glass flowing back from the cooling part L to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com