Proportional bio-diesel and preparation method thereof

A biodiesel and blending technology, applied in biofuels, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of easy deterioration of unsaturated fatty acids, complicated processes, excessive alcohol, etc., and achieve normal atomization, high calorific value, Storage stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mineral diesel oil 45%, vegetable oil 30%, methanol 18%, sodium dodecylsulfonate 2.0%, OP emulsifier 1.5%, triethanolamine 2.0%, naphthenic acid 1.49%, biological compound enzyme 0.01%, the percentage is mass percentage.

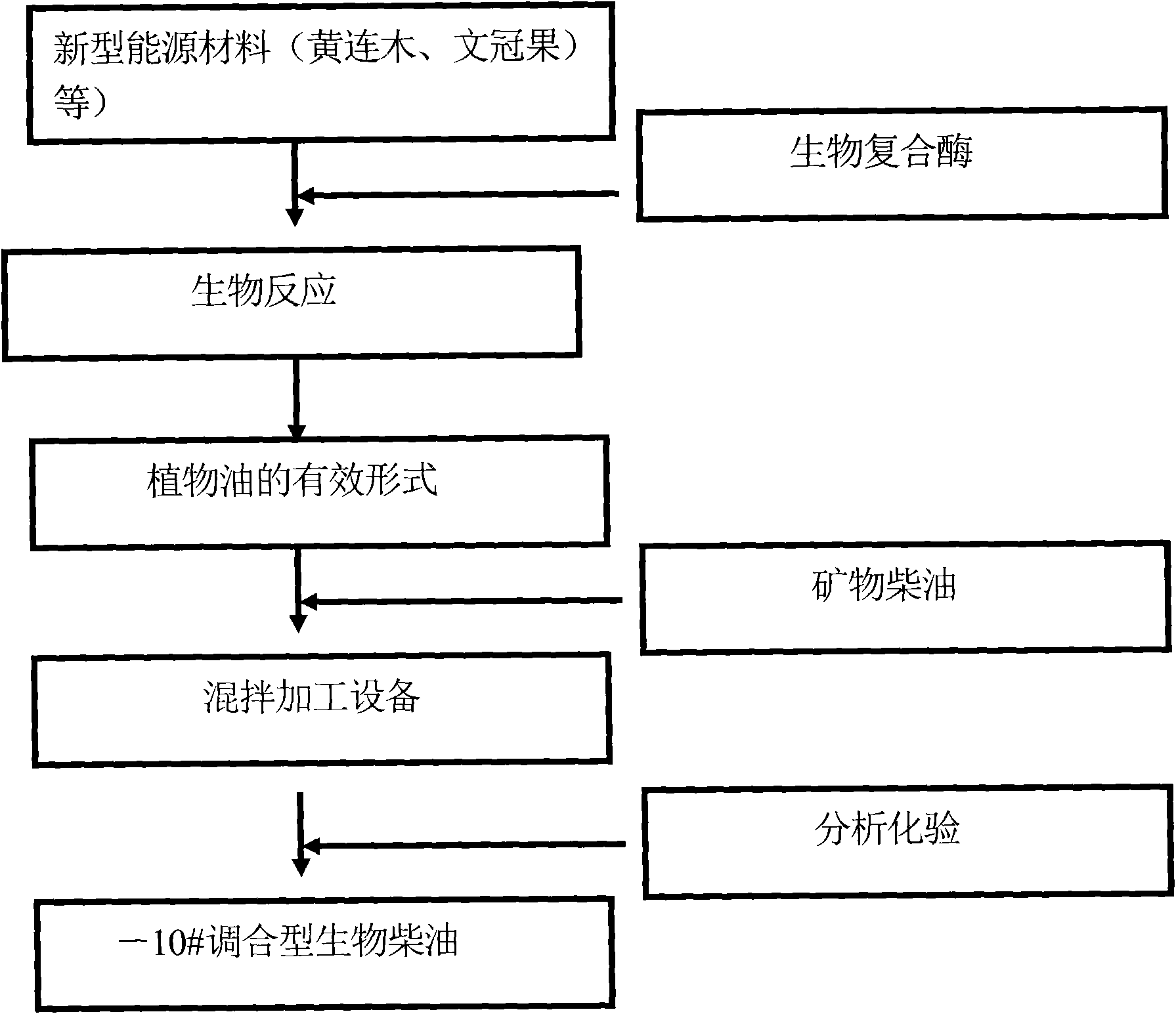

[0021] The preparation method is: as shown in the figure, mix vegetable oil with methanol, sodium dodecylsulfonate, OP emulsifier, and triethanolamine according to the above mass percentage; slowly pour the mixed solution into mineral diesel oil while stirring , and at the same time, add naphthenic acid and biological compound enzyme according to the mass percentage requirements, stir and mix thoroughly, and then the -10# blended biodiesel that can be stored for more than half a year without stratification can be obtained.

Embodiment 2

[0023] Mineral diesel 60%, vegetable oil 25%, methanol 10%, sodium dodecylsulfonate 1.0%, OP emulsifier 1.5%, triethanolamine 1.0%, naphthenic acid 1.48%, biological compound enzyme 0.02%, the percentage is mass percentage.

Embodiment 3

[0025] Mineral diesel 60%, vegetable oil 20%, methanol 14%, sodium dodecylsulfonate 1.0%, OP emulsifier 1.5%, triethanolamine 2.0%, naphthenic acid 1.48%, biological compound enzyme 0.02%, the percentage is mass percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com