Wet flue gas desulfurization (WFGD) process for gypsum through oxidization in tower by using calcium-based strongly basic substance

A technology of wet flue gas desulfurization and internal oxidation, applied in chemical instruments and methods, calcium/strontium/barium sulfate, separation methods, etc., can solve the problems of large equipment investment and high operating costs, and achieve environmental pollution, spraying The effect of reducing the leaching resistance and avoiding the problem of oxidation facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

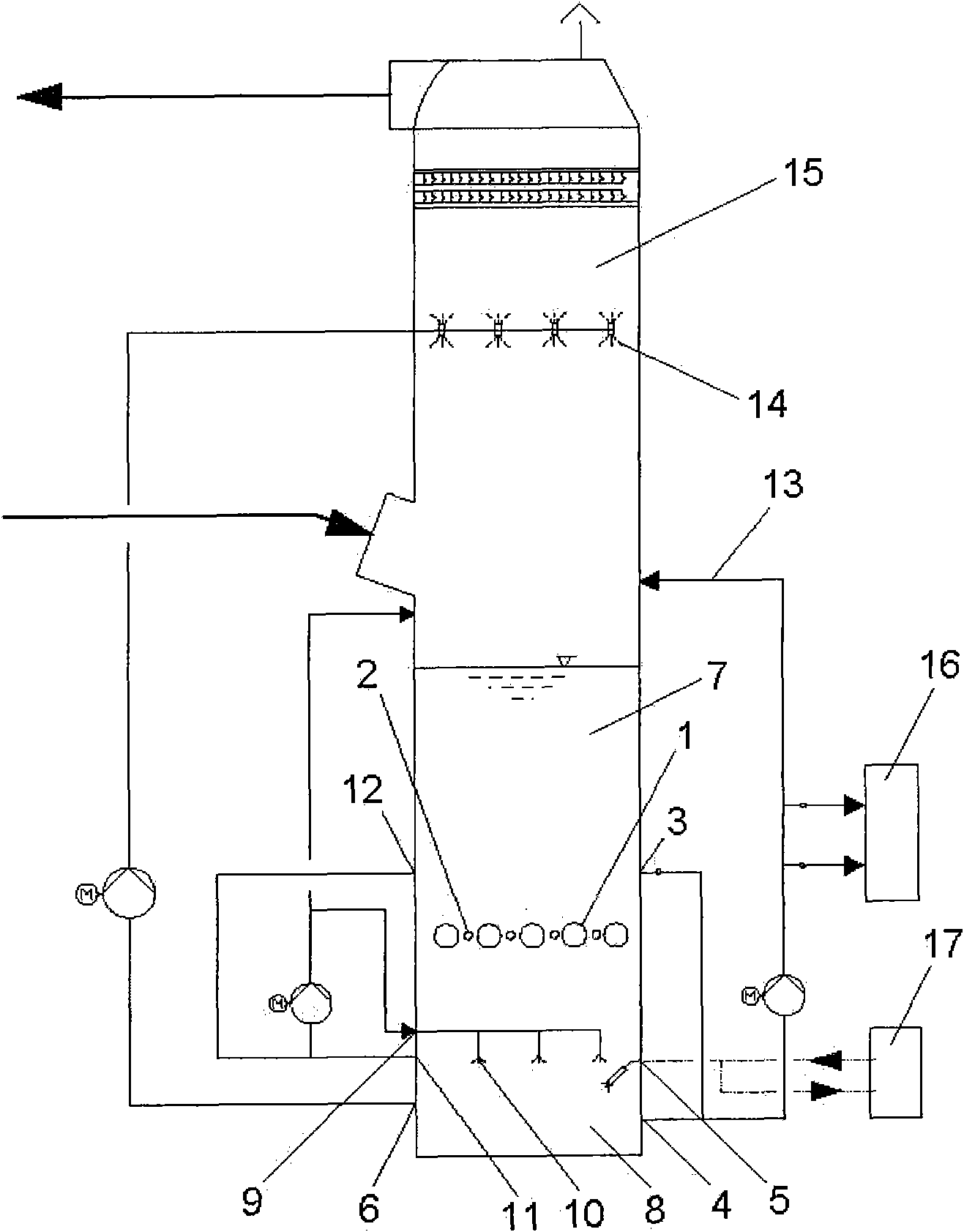

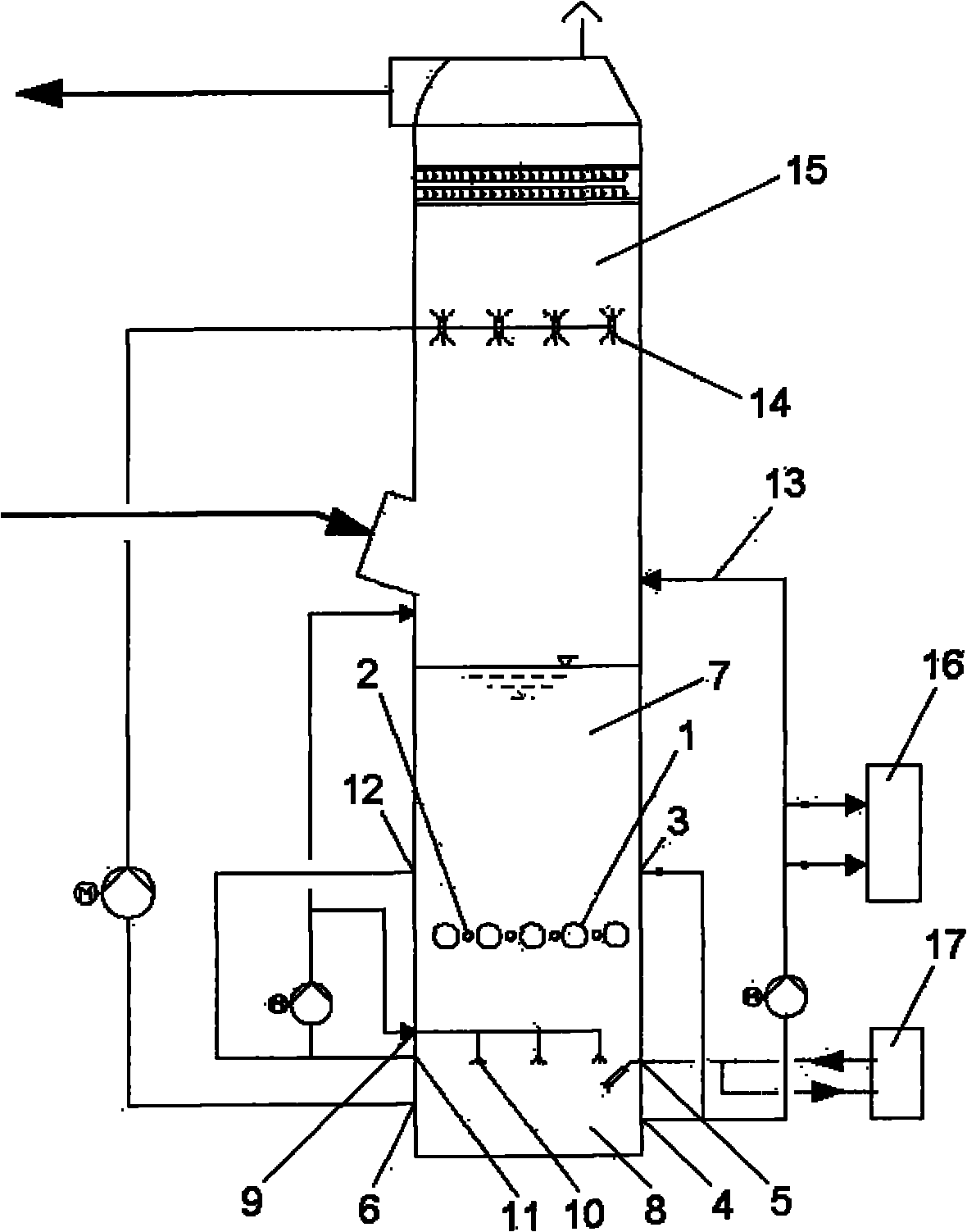

[0021] figure 1 It is the working flow chart of the absorbing tower. It can be seen from the figure that the calcium oxide-based strong alkali gypsum wet flue gas desulfurization process in the tower includes the flue gas desulfurization of the absorbing tower, the slurry supply, circulation and discharge of the absorbent slurry, and the dehydration of the gypsum. system, characterized in that:

[0022] (1) In the slurry tank of the absorption tower, the oxidation automatic isolator 1 and the oxidation air pipe 2 are alternately arranged and arranged alternately, and the entire slurry tank is divided into upper and lower parts: the upper low pH value zone 7 and the lower high pH value zone 8;

[0023] (2) Absorbent slurry tanks use calcium-based strong alkali substances, such as quicklime, slaked lime or carbide slag, etc., which are digested to make absorbent slurry, which is pumped into the slurry pool of the absorption tower by the slurry supply pump 17 and placed at a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com